No.0 block supporting structure suitable for rigid frame bridge and construction method of No.0 block supporting structure

A technology for supporting structures and rigid-frame bridges, applied in bridges, bridge construction, bridge parts, etc., can solve the problem of time-consuming and labor-intensive bracket installation, and achieve the effect of saving materials, saving material consumption, and speeding up turnover.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

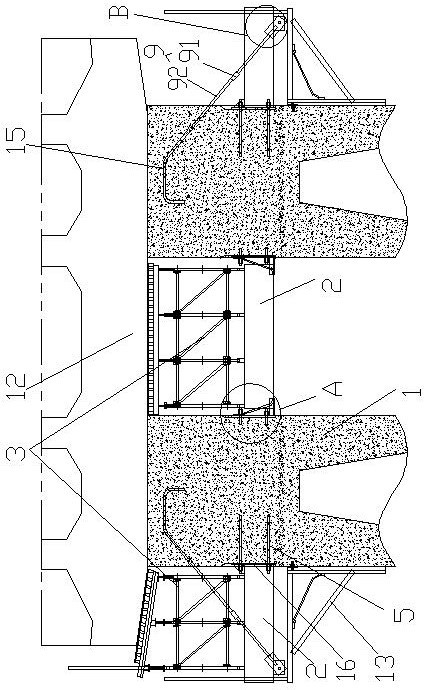

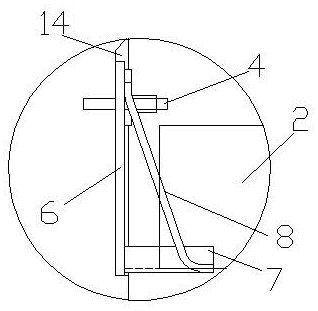

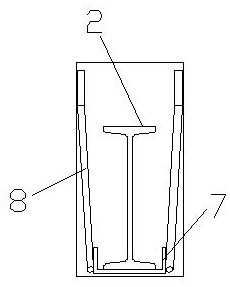

[0035] Example 2, which differs from Example 1 in that, as figure 2 and image 3 As shown, the support platform includes a steel plate one 6 detachably connected with the embedded bolts 4 and a channel steel 7 vertically connected to the lower part of the steel plate one 6. The outside of the channel steel 7 is also connected to the steel plate one 6 through a reinforcing connecting rod 8. The reinforcing connecting rod 8 includes a vertical section and a horizontal section fixed to the outside of the steel plate 1 6 and the channel steel 7 respectively, and the vertical section and the horizontal section are connected by a transition through inclined ends. The opening of the channel steel 7 is upward, and the two ends of the support beam 2 are respectively supported and placed in the opening of the channel steel 7 of a pair of supporting platforms.

Embodiment 3

[0036] Example 3, the difference from Example 1 is that, as Figure 4 and Figure 5 As shown, the connection mechanism includes a second steel plate 16 detachably connected to the threaded steel 5 , the support beam 2 is vertically fixed on the second steel plate 16 , and a reinforcing rib plate is also provided between the support beam 2 and the second steel plate 16 .

Embodiment 4

[0037] Embodiment 4, a construction method applicable to the support structure of the No. 0 block of a rigid frame bridge, including the above-mentioned support structure applicable to the No. 0 block of a rigid frame bridge, and also comprising the following steps:

[0038] S1. Construction of pre-embedded parts: During the construction of the top section of pier column 1 of a thin-walled hollow pier with double limbs, a certain size of groove is reserved, and the inner side of the pier column 1 is pre-embedded with pre-embedded nuts 4, and the outer side is pre-embedded with precision-rolled rebar. 5 and bending embedded parts 15;

[0039] S2, the processing of the support platform, that is, the components of the support platform include a steel plate 6, a channel steel 7 and a reinforcing connecting rod 8 to be welded and connected;

[0040] S3. The erection of the support system on the inner side of the pier column 1: including bolting the steel plate 1 6 of the supporting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com