Sludge well easy to clean

A sedimentation well and sewage cleaning technology, applied in water/sludge/sewage treatment, sewer pipe cleaning, water/sewage treatment, etc., can solve the problems of inability to effectively guarantee the personal safety of dredging workers, poor dredging effect, and high cost problems, achieve thorough desilting effect, facilitate production and construction, and ensure health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

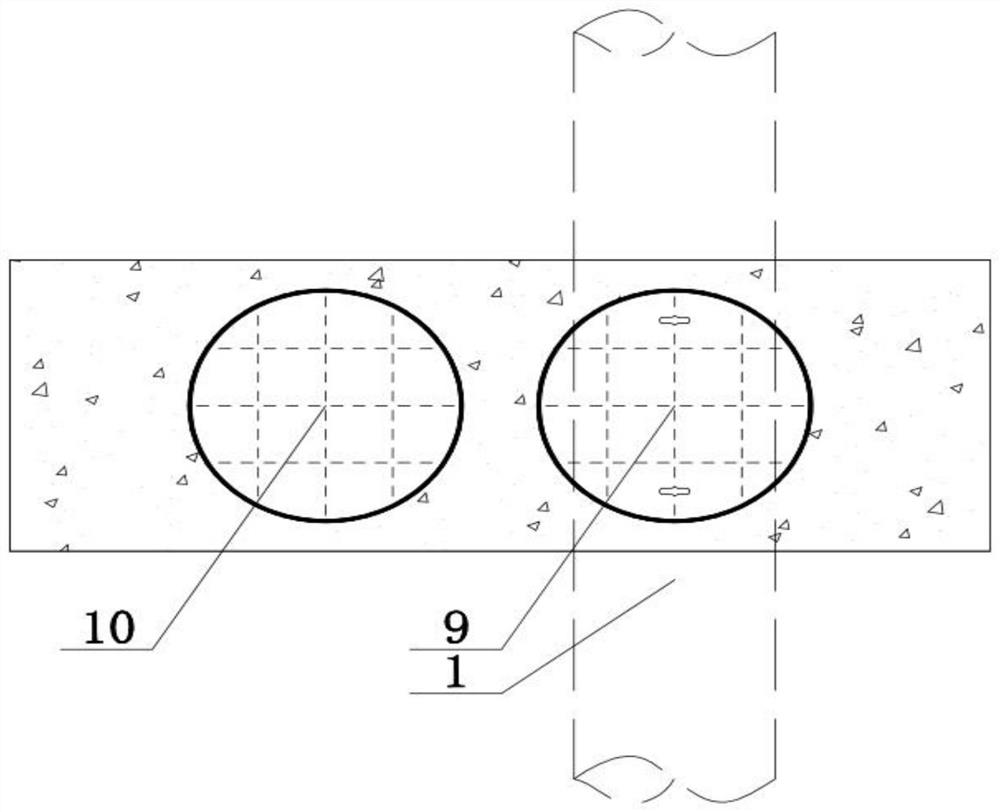

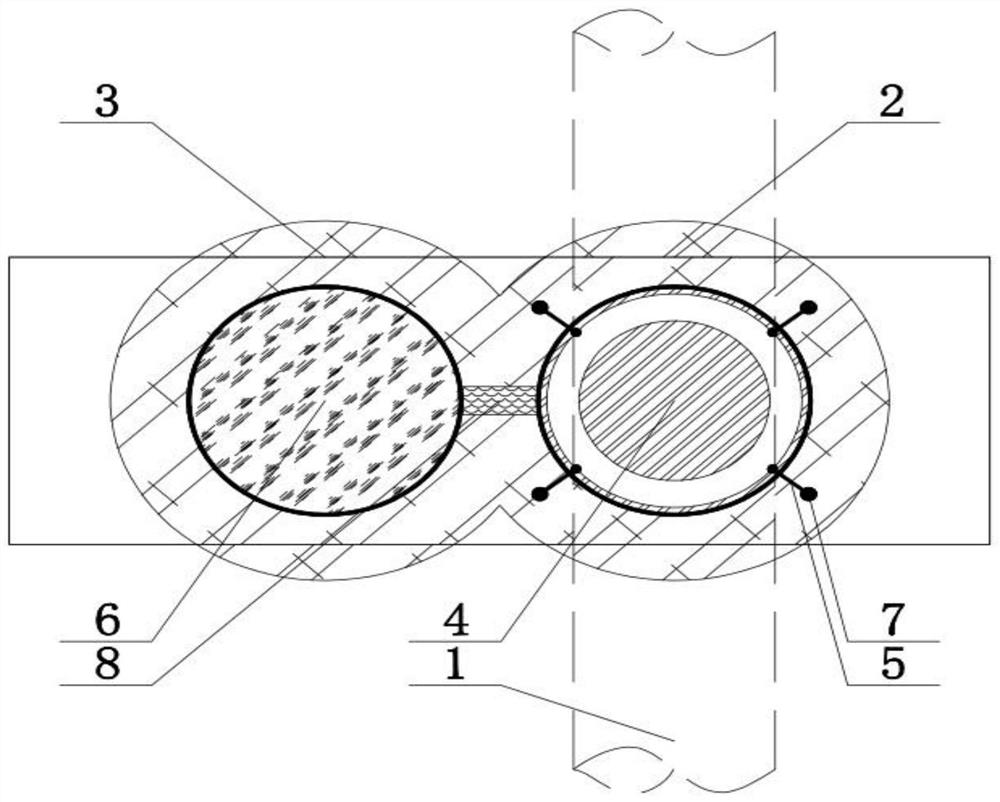

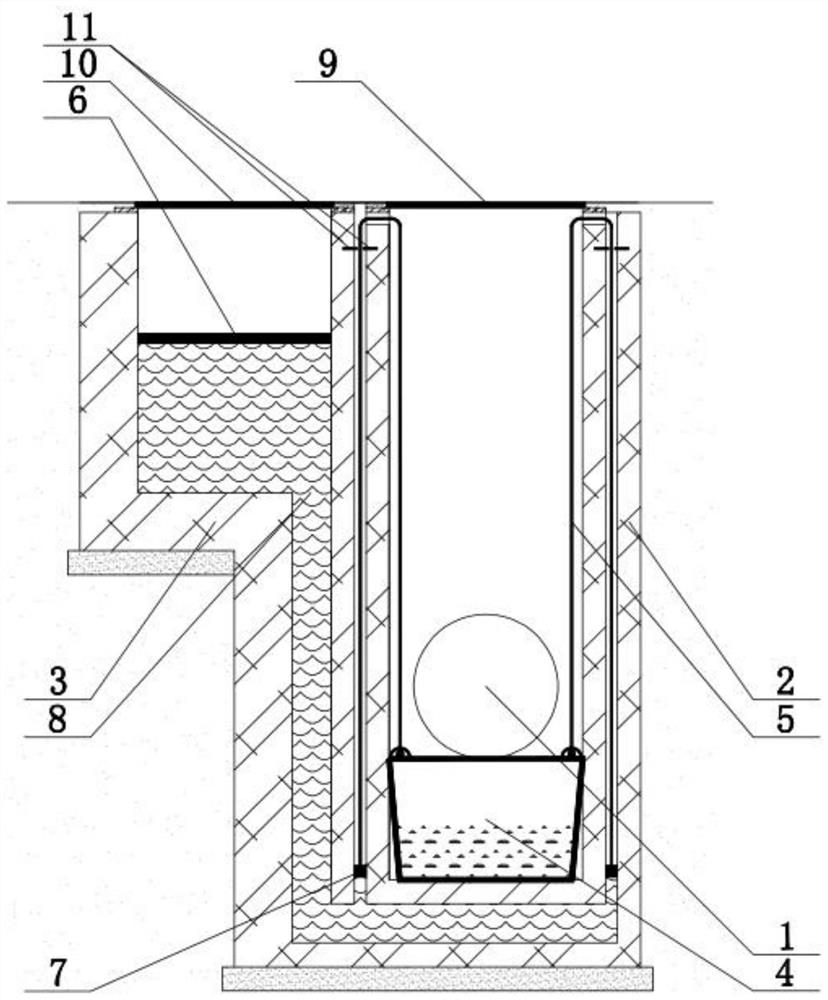

[0026] The present invention provides an easy-to-clean silt well. In order to make the purpose, technical solution and use effect of the present invention clearer and clearer, the present invention is further described in detail below with reference to the accompanying drawings.

[0027] see figure 2 and image 3 , An easy-to-clean type silt well provided by the present invention is characterized in that: the movable silt tank (4) is arranged at the bottom of the silt well (2), and the movable silt tank (4) is connected to the bottom of the silt well (2). The working piston (7) of the hollow part of the outer wall of the mud well (2) is connected by a transmission rod (5). The space part under the power piston (6) located in the control well (3) is communicated with the hollow part under the working piston (7) arranged in the outer wall of the silt well (2), and the space between the two pistons is filled with hydraulic pressure Oil (8), together form a simple hydraulic con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com