Multi-inner-core pressure forming concrete filled steel tube composite member and manufacturing method thereof

A technology of steel tube concrete and laminated components, applied in the field of steel tube concrete, can solve the problems of not conforming to the design concept of strong joints, weakening the mechanical properties of joint positions, and poor fire resistance of FRP pipes, so as to achieve enhanced synergistic effects, delay temperature transfer speed, Good molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to have a clearer understanding of the technical features, objects and effects of the present invention, the specific embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

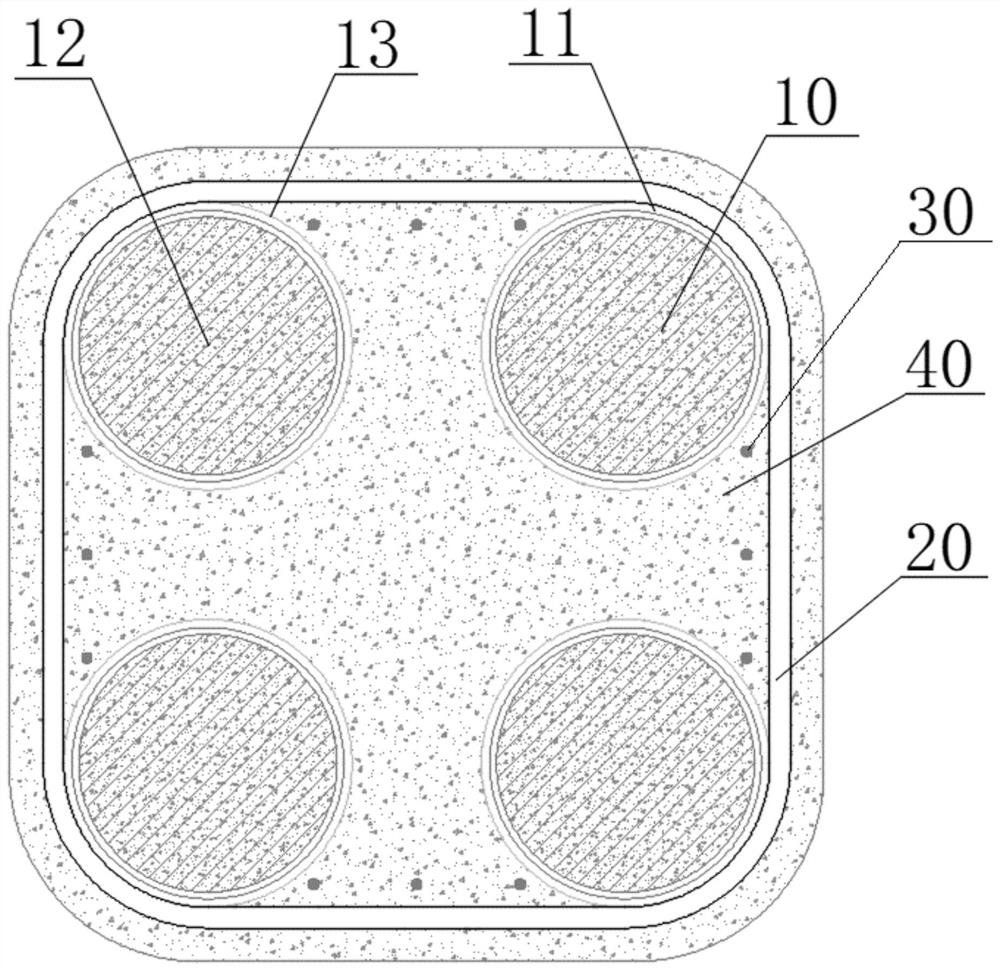

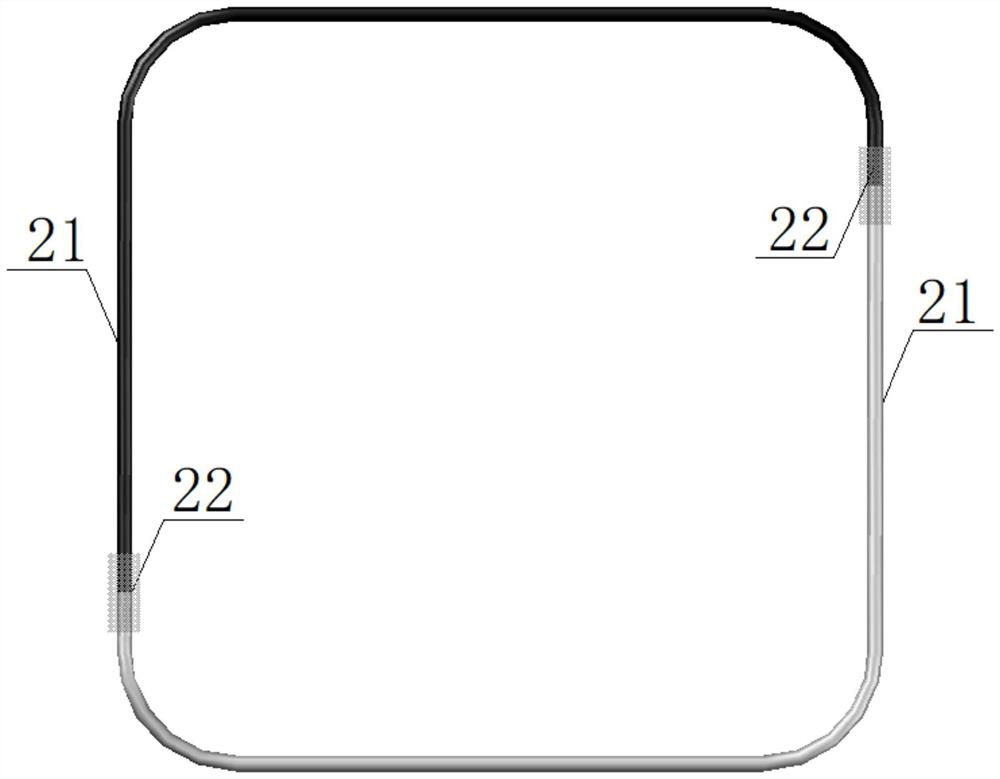

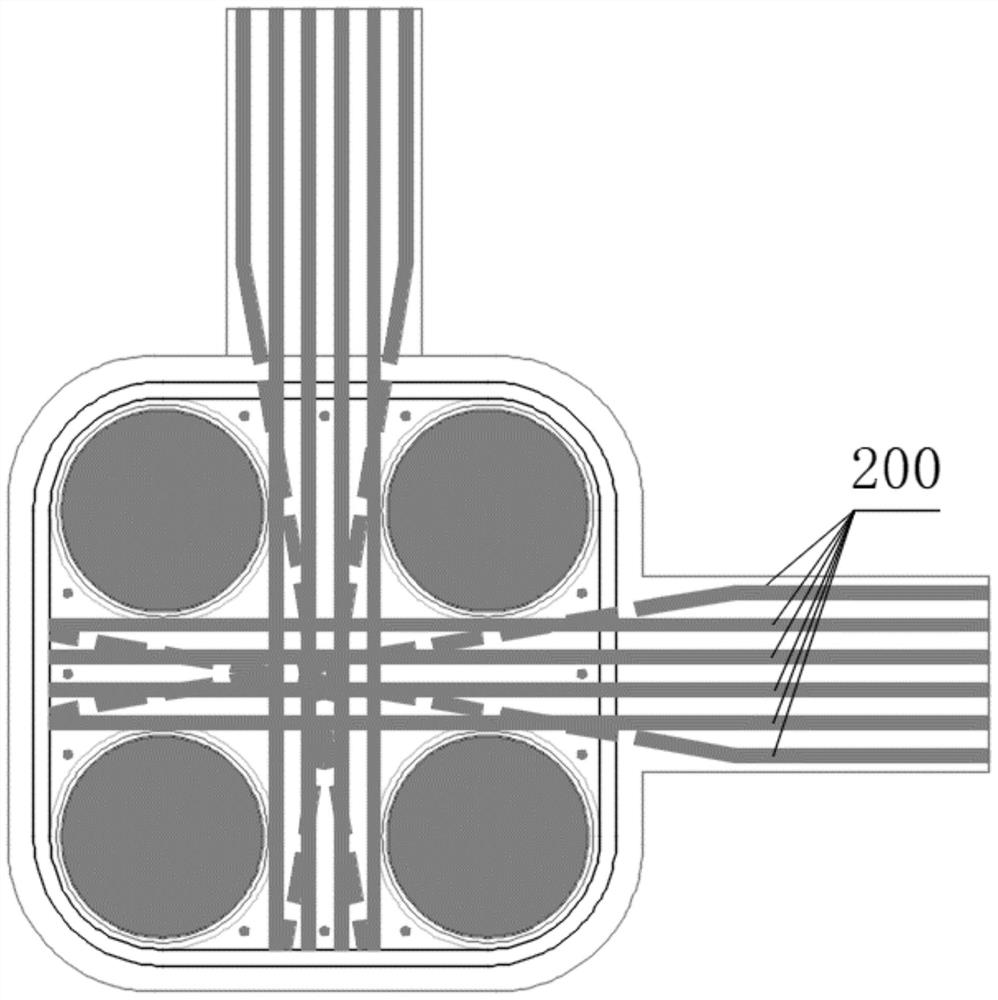

[0038] like figure 1 As shown, a multi-core pressure-formed concrete-filled steel tubular composite member provided in the first embodiment of the present invention includes four pressure-formed concrete-filled steel tubular core columns 10 , stirrups 20 and peripheral concrete 40 . The pressure-formed concrete-filled steel tubular core column 10 includes a steel pipe 11, a pressure-formed concrete 12 poured inside the steel pipe 11, and a fiber composite material 13 coated on the outer surface of the steel pipe 11. Make the concrete more dense, thereby improving the axial bearing capacity of the CFST core column. The stirrups 20 are bound on the periphery of the four pressure-formed concrete-filled steel tubular core columns 10 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com