Steel reinforced concrete composite structure beam column core area joint structure and construction method

A technology for concrete beams and composite structures, which is applied to structural elements, building structures, building components, etc., can solve problems such as difficult construction, weakening cross-sectional strength, and affecting the performance of steel materials, so as to facilitate on-site operation and construction and improve construction efficiency. , the effect of novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

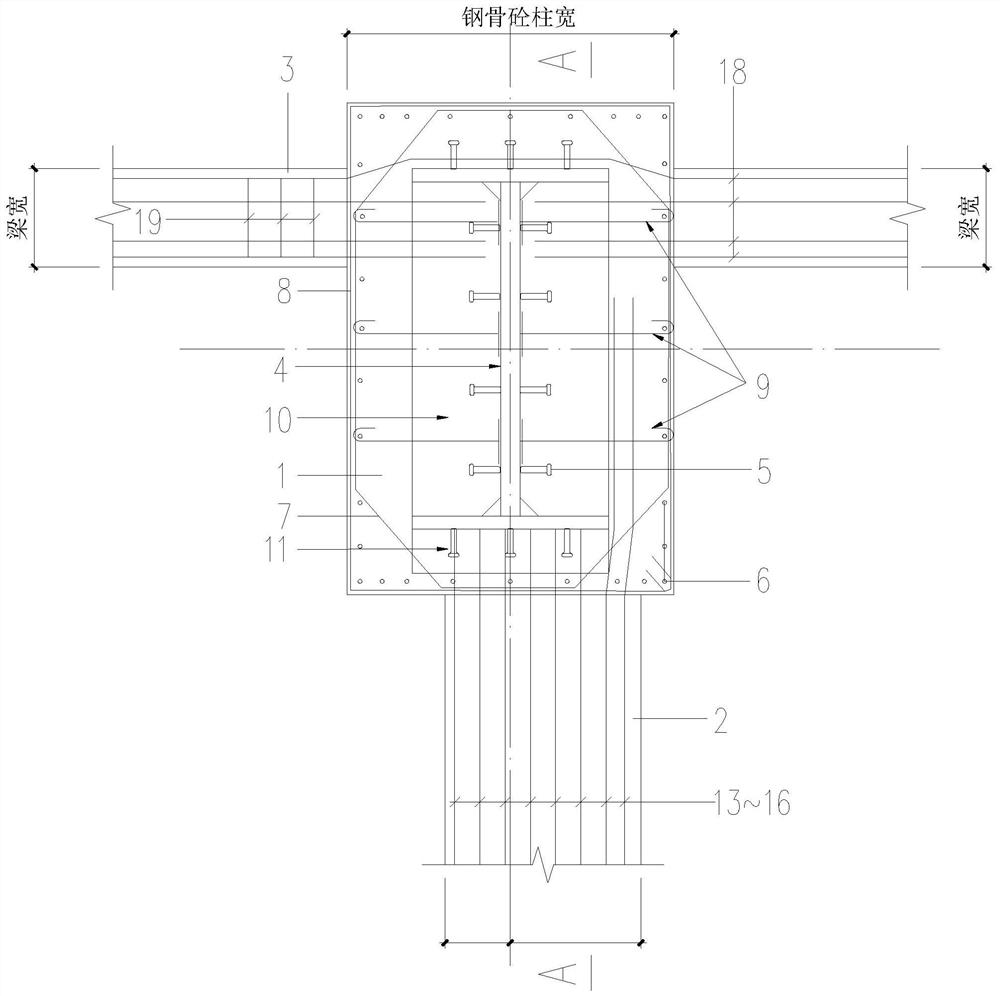

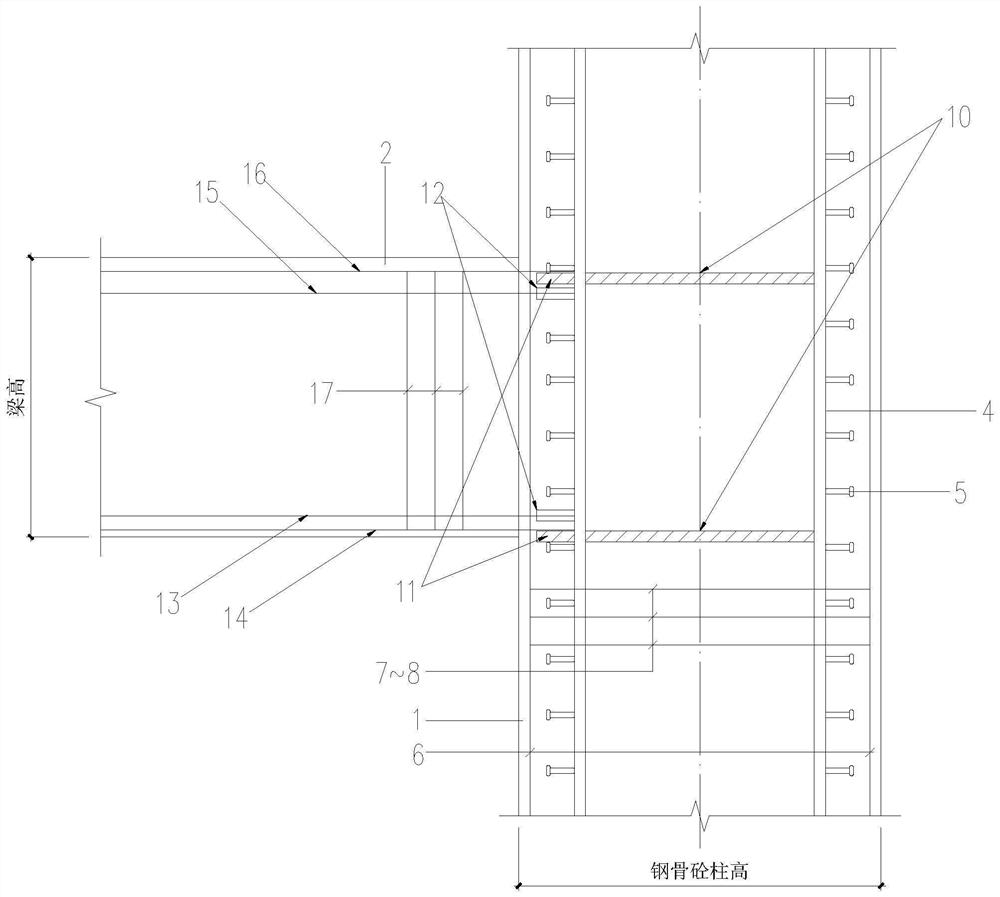

[0029] like figure 1 and figure 2 As shown in the figure, a joint structure of the beam-column core area of a profiled steel-concrete composite structure of the present invention includes a steel-reinforced concrete column 1 and a flange-direction concrete beam 2 and a web-direction concrete beam 3 respectively connected with the steel-reinforced concrete column 1; The steel reinforced concrete column 1 includes a profiled steel column 4 in an "H" shape and a number of longitudinal reinforcement bars 6 arranged on the outer periphery of the profiled steel column 4. The profiled steel column 4 may preferably have a cross-section of H1100*600*60*60, and the H-shaped steel of the trade mark Q355B. , a number of studs 5 can also be set on it to improve its strength, and the longitudinal reinforcement bars 6 of each column are provided with a number of octagonal stirrups 7 and peripheral stirrups 8 from bottom to top in the longitudinal direction. Several reinforcement hooks 9 ...

Embodiment 2

[0035] The construction method of the beam-column core area node structure of a profiled steel-concrete composite structure described in Embodiment 1 includes the following steps:

[0036] A. Process and manufacture the profiled steel column 4 according to the design drawings, and at the corresponding position of the profiled steel column 4, complete the welding and installation work of the steel corbel 11, the first threaded sleeve 12, the second threaded sleeve and the stiffening plate 10;

[0037] B. Complete the binding, formwork installation and concrete pouring of the longitudinal reinforcement bars 6, octagonal stirrups 7, peripheral stirrups 8 and reinforcement hooks 9 at the lower part of the steel reinforced concrete column 1 in the beam-column core area of the beam-column core area of the steel-concrete composite structure. In the flange direction and web direction of the profiled steel column 4 of the bone concrete column 1, install the beam bottom formwork of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com