Lubricating oil way structure of gear box

A technology of lubricating oil circuit and gear box, applied in the direction of gear lubrication/cooling, components with teeth, belt/chain/gear, etc. Improper, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

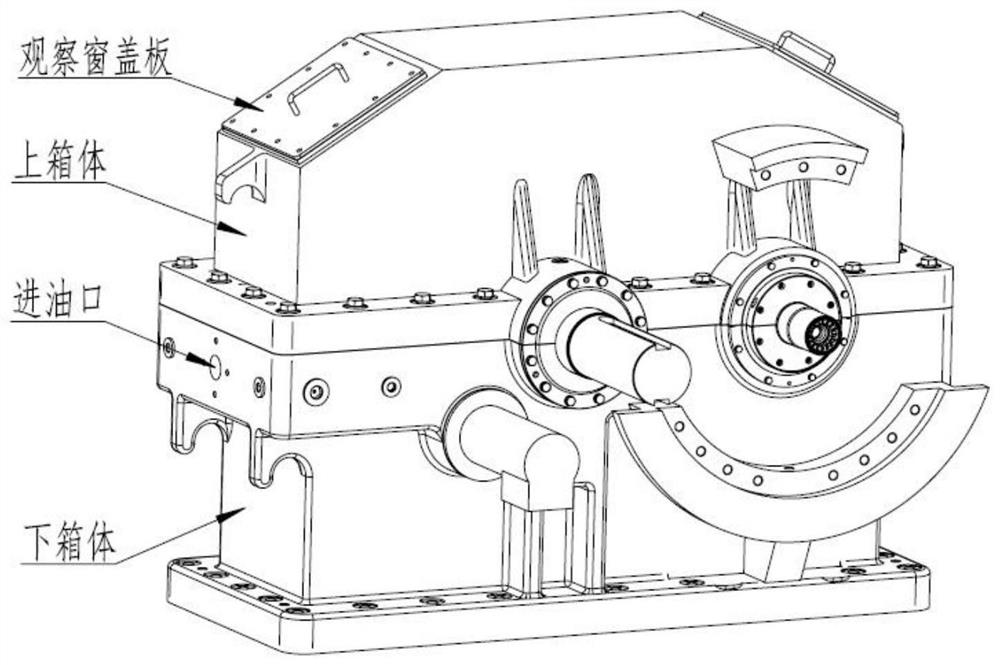

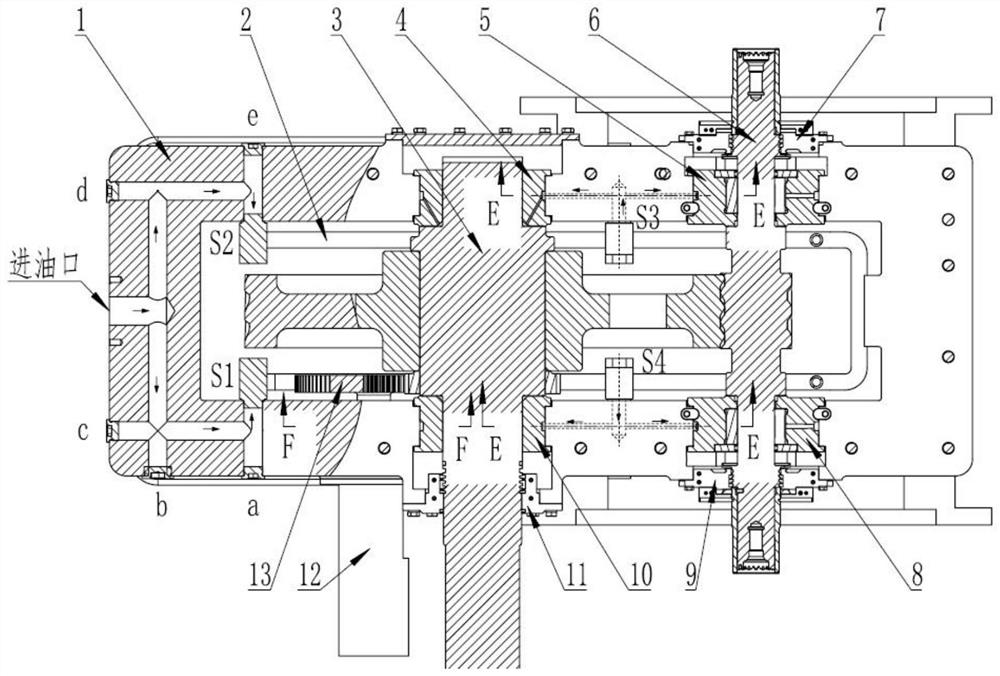

[0022] see Figure 1-Figure 5 , which is an embodiment of a lubricating oil circuit structure of a gearbox.

[0023] figure 1 It is an appearance diagram of a gearbox of the present invention, which is a horizontally split gearbox up and down, and the upper and lower boxes are connected by screws, because the upper box needs to be disassembled when the gearbox is overhauled. It is fully arranged in the lower box, and the observation window is used to observe the gear meshing and oil injection lubrication.

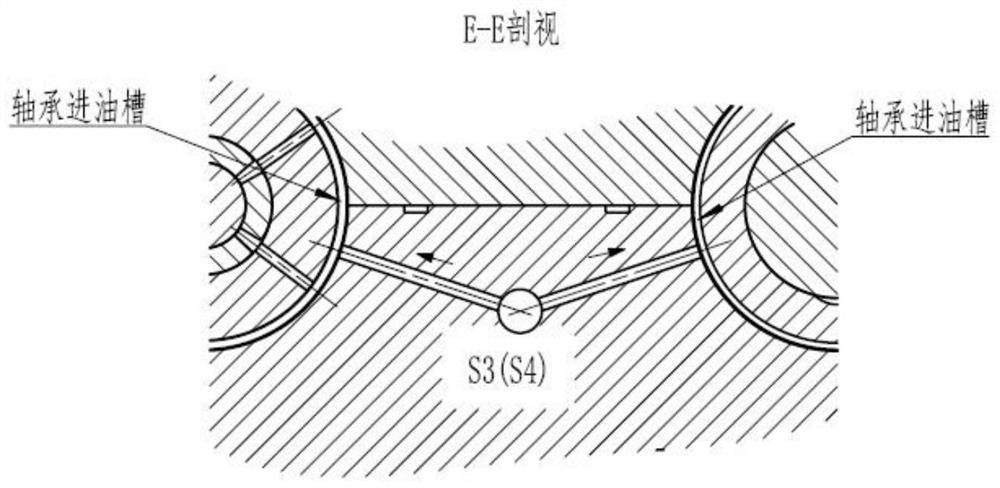

[0024] figure 2 It is a horizontal sectional view of the oil inlet of the gearbox of the present invention, wherein there are input gears and oil pump driving gears on the low-speed shaft 3, and oil pump driven gears are installed on the oil pump shaft 13, wherein the input gear and the high-speed gear shaft 6 (with small Gear) meshing, the oil pump driving gear meshes with the oil pump driven gear, the low-speed front bearing 4 and the low-speed rear bearing 10 support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com