Venturi type high-speed cavitation water tunnel testing device

A Venturi-type, test device technology, applied in the field of Venturi-type high-speed cavitation water tunnel test device, can solve the problems of inability to conduct cavitation water tunnel test research, not easy to cavitate, and low water flow velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

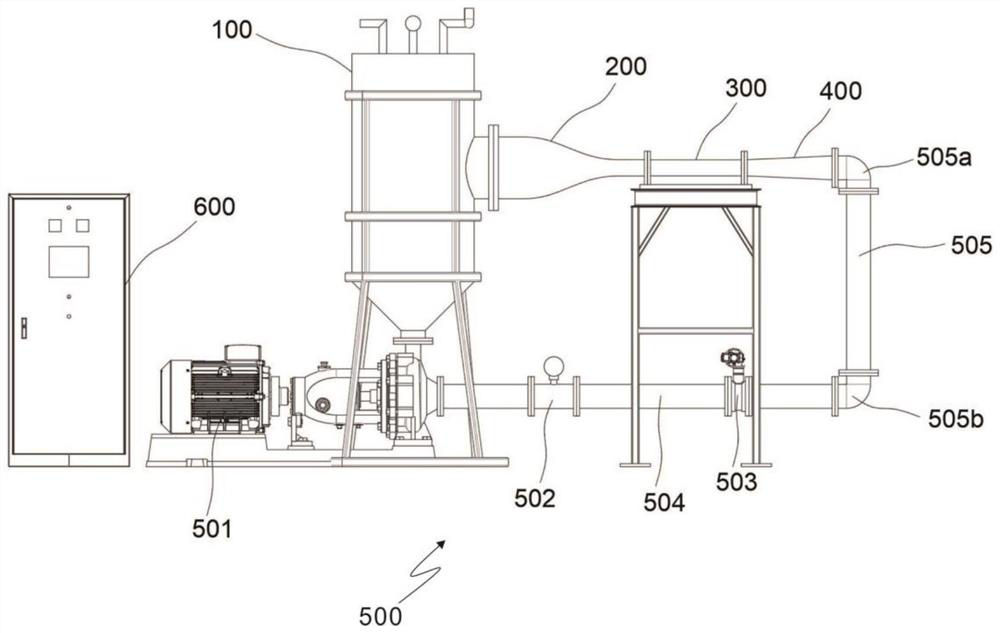

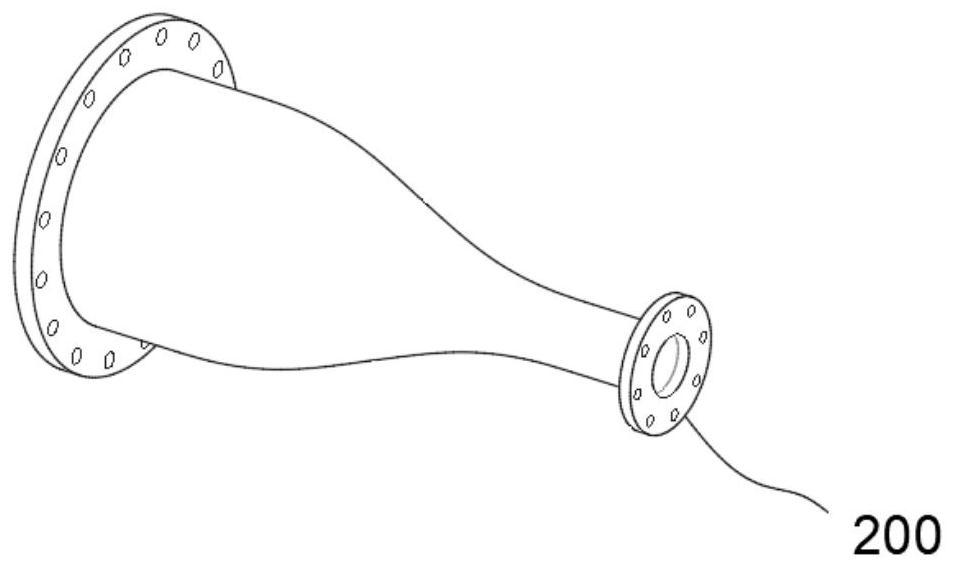

[0032] refer to figure 1 , is the first embodiment of the present invention, which provides a Venturi type high-speed cavitation water tunnel test device, including a tank body 100 , a constriction section 200 , a test section 300 , a diffusion section 400 and a connection assembly 500 . The tank body 100 is provided with a water inlet 101 , a water outlet 102 and a return outlet 103 . The constricted section 200 is connected to the water outlet 102 . The test section 300 includes a tube shell 301 and a venturi tube 302 arranged in the tube shell 301 , and the test section 300 is connected to the end of the constricted section 200 away from the water outlet 102 . The diffusion section 400 is connected to the end of the test section 300 away from the constriction section 200 . One end of the connection assembly 500 is connected to one end of the diffusion section 400 away from the test section 400 , and the other end is connected to the return port 103 . The connection assem...

Embodiment 2

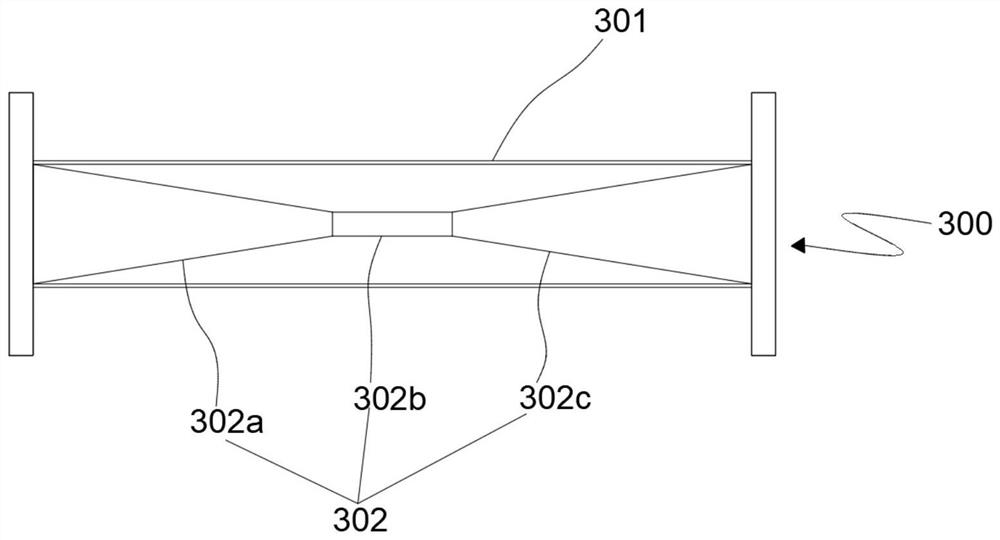

[0035] refer to figure 2 , image 3 , is the second embodiment of the present invention, which is based on the previous embodiment, and the difference is that the venturi 302 includes an inlet pipe 302a, a throat pipe 302b and an outlet pipe 302c. One end of the inlet pipe 302a is matched with one end of the constricted section 200 away from the water outlet 102, the diameter of the inlet pipe 302a decreases toward the other end, the diameter of the throat pipe 302b is the same everywhere and is matched with the inlet pipe 302a, and the structure of the outlet pipe 302c is the same as that of the inlet pipe 302a And the end with the smaller diameter is matched with the throat pipe 302b. The inlet pipe 302a, the throat pipe 302b and the outlet pipe 302c are sequentially connected to form a whole. The overall cross-section of the venturi tube 302 shows a trend of first decreasing and then increasing. The diameter of the inlet pipe 302a varies linearly, and the ratio of the d...

Embodiment 3

[0039] refer to Figure 4 , Figure 5, is the third embodiment of the present invention, which is based on the previous embodiment, and the difference is that the tank body 100 is provided with an inner side plate 104 connected to the water outlet 102 . The inner side plate 104 includes a first straight plate 104a, a second straight plate 104b, a third straight plate 104c, and a bottom plate 104d. The first straight plate 104a and the second straight plate 104b have the same height and are connected vertically. The second straight plate 104b and the third straight plate 104c have the same height and are vertically connected. One side of the bottom plate 104d is connected to the first straight plate 104a, the second straight plate 104b, the The bottom of the three straight plates 104c is a rectangular shape, and the other side is an arc shape matched with the inner wall of the tank body 100 . The bottom of the water outlet 102 is parallel to the bottom plate 104 d , and the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com