Polarizing plate and method for producing same

A manufacturing method and polarizer technology, applied in polarizing elements, identification devices, instruments, etc., can solve problems such as no prompt alternatives, and achieve the effects of improved color durability and excellent polarization degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0213] A transparent unstretched polyvinyl alcohol (PVA) film (PE60, KURARAY) with a saponification degree of 99.9% or more was immersed in water (deionized water) at 25° C. for 1 minute and 20 seconds to swell, and then iodine-containing Dyeing was performed by immersion in an aqueous solution for dyeing at 30°C of 1 mM / L, 1 wt % of potassium iodide and 0.3 wt % of boric acid for 2 minutes and 30 seconds. At this time, in the swelling and dyeing steps, stretching was performed at a stretching ratio of 1.56 times and 1.64 times, respectively, so that the cumulative stretching ratio after passing through the dyeing tank was 2.56 times. Then, it was immersed in an aqueous solution for crosslinking at 56° C. containing 13.9% by weight of potassium iodide, 3% by weight of boric acid, and 0.5% by weight of zinc nitrate from Oi Kakin Co., Ltd. for 26 seconds (first crosslinking step) to crosslink it. Stretching was performed at a draw ratio of 1.7 times. Then, it was immersed in an...

Embodiment 2 to 8 and comparative example 1 to 3

[0217] In addition to the composition (type and concentration), temperature, total cumulative draw ratio, and metal salt content relative to the total weight of the polarizer of the metal salt in the crosslinking liquid or the color correction liquid, as described in Tables 1 and 2 below Except for this, a polarizing plate was produced by the same method as in Example 1.

[0218] [Table 1]

[0219]

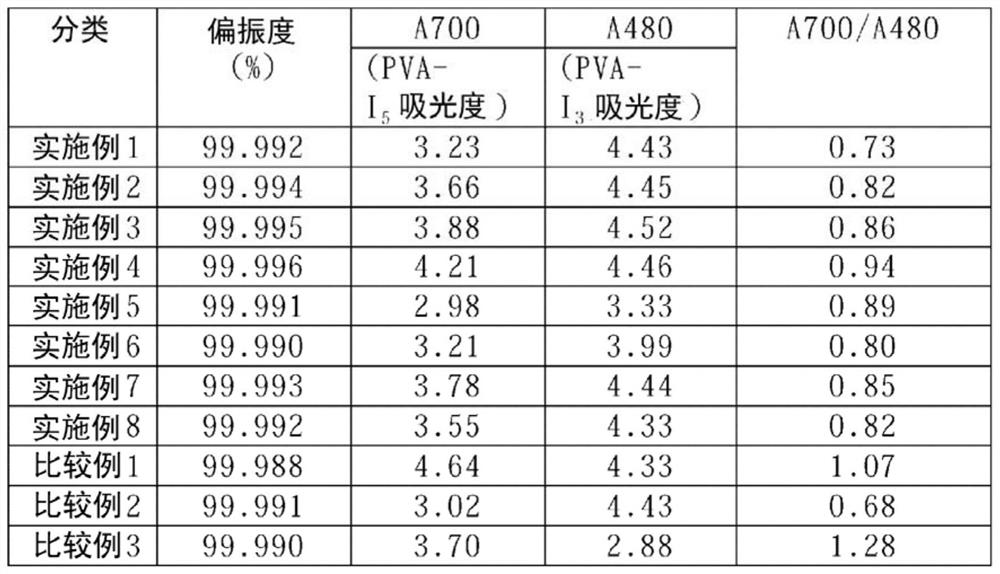

[0220] [Table 2]

[0221]

[0222] Analysis example

[0223] The distance between the crystals in the PVA of the polarizing plate manufactured in the said Example and the comparative example was measured by the following method.

[0224] (1) Distance between crystals in PVA (Long Period)

[0225] Using the Synchrotron Beam of Pohang Accelerator Institute (PAL), the distance from the sample to the detector was set to 3.0 m at the X-ray wavelength of 1.567 angstroms, and the peak of the scattering vector q was measured until the beam path 1 mm passed through the dyeing tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com