Method and device for determining multiaxial fatigue load spectrum

A fatigue load spectrum and determination method technology, applied in the field of multiaxial fatigue load spectrum determination method and device, can solve the problems of inability to obtain fatigue load spectrum, high cost, and high requirements for bench equipment, so as to improve reliability and apply performance, reducing the number of determinations and verifications, ensuring durability and longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

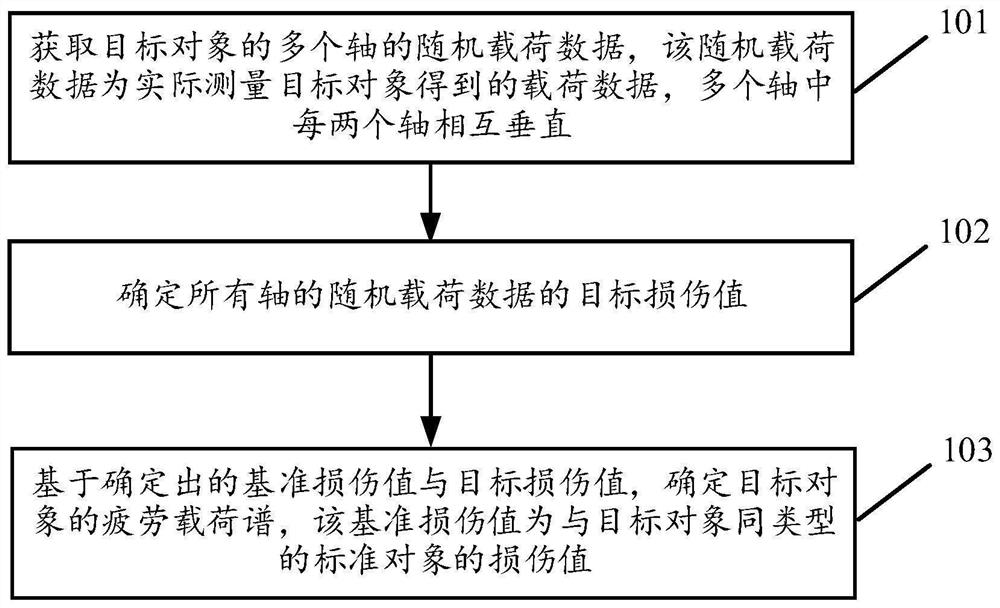

[0036] see figure 1 , figure 1 It is a schematic flowchart of a method for determining a multiaxial fatigue load spectrum disclosed in an embodiment of the present invention. like figure 1 The method shown can be applied in the fatigue load spectrum determination system / fatigue load spectrum determination device / fatigue load spectrum determination terminal, as in figure 1 As shown, the multiaxial fatigue load spectrum determination method may include the following operations:

[0037] 101. Acquire random load data of multiple axes of the target object, where the random load data is load data obtained by actually measuring the target object, and every two axes of the multiple axes are perpendicular to each other.

[0038] In this embodiment of the present invention, the target object includes parts of any article (for example, a car).

[0039] In this embodiment of the present invention, the random load data of the multiple axes includes at least two axes of random load data,...

Embodiment 2

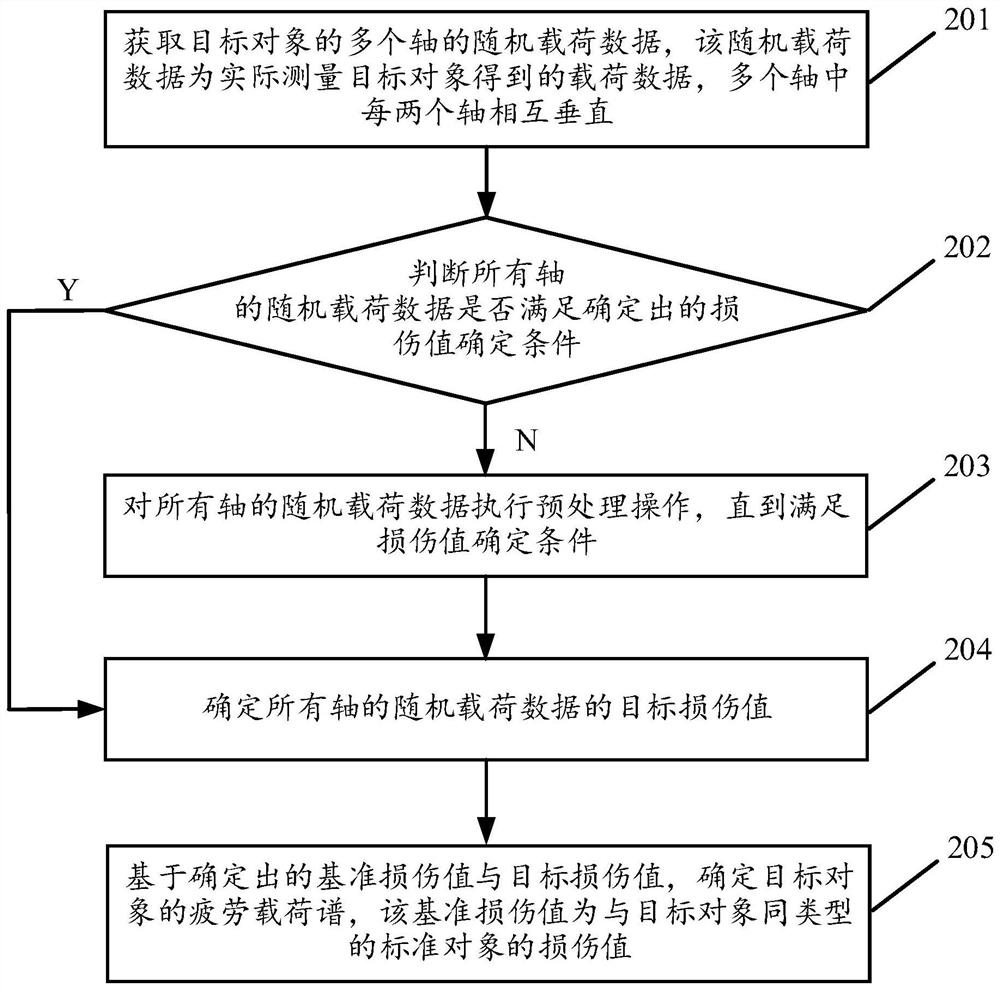

[0098] see figure 2 , figure 2 It is a schematic flowchart of another multiaxial fatigue load spectrum determination method disclosed in the embodiment of the present invention. like figure 2 The method shown can be applied in the fatigue load spectrum determination system / fatigue load spectrum determination equipment / fatigue load spectrum determination terminal, such as figure 2 As shown, the multiaxial fatigue load spectrum determination method may include the following operations:

[0099] 201. Acquire random load data of multiple axes of the target object, where the random load data is load data obtained by actually measuring the target object, and every two axes of the multiple axes are perpendicular to each other.

[0100]202. Determine whether the random load data of all axes meet the determined damage value determination conditions; when it is determined that the damage value determination conditions are not met, trigger step 203; when it is determined that the ...

Embodiment 3

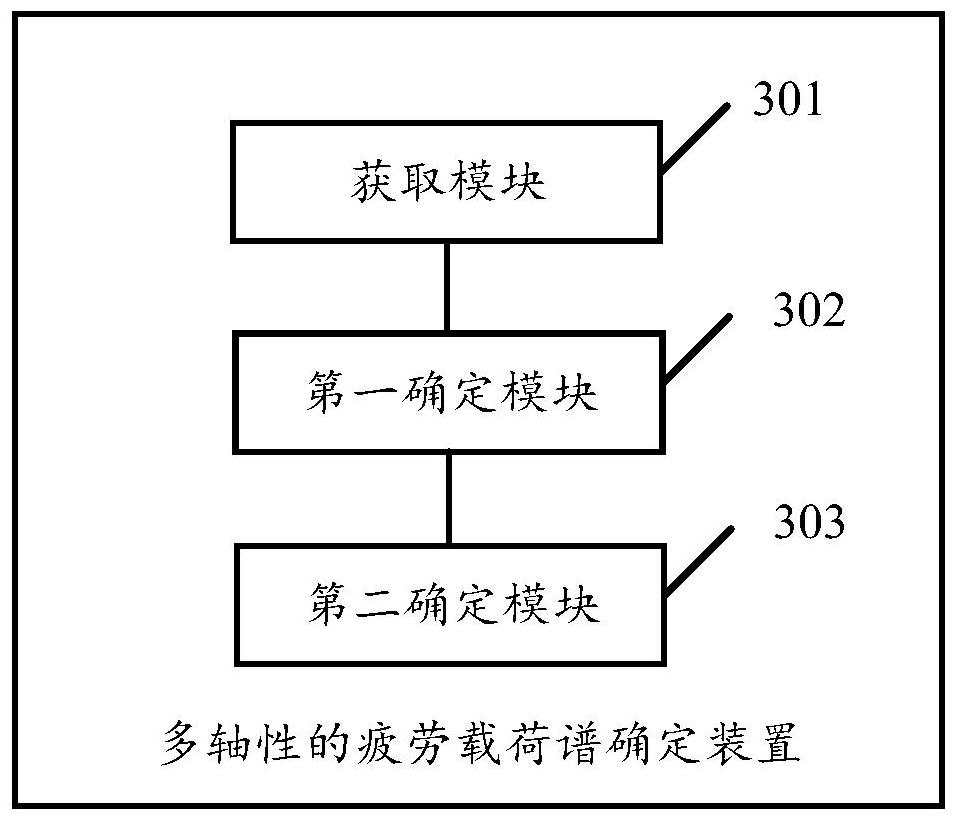

[0116] see image 3 , image 3 It is a schematic structural diagram of a multiaxial fatigue load spectrum determination device disclosed in the embodiment of the present invention. like image 3 The apparatus shown can be applied in a fatigue load spectrum determination system / fatigue load spectrum determination device / fatigue load spectrum determination terminal, such as image 3 As shown, the multiaxial fatigue load spectrum determination device may include: an acquisition module 301, a first determination module 302 and a second determination module 303, wherein:

[0117] The acquiring module 301 is configured to acquire random load data of multiple axes of the target object, where the random load data is the load data obtained by actually measuring the target object, and every two axes of the multiple axes are perpendicular to each other.

[0118] The first determination module 302 is used for determining the target damage value of the random load data of all axes.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com