Vibrating-type material level switch suitable for flammable and explosive environment with high temperature and high pressure

A flammable, explosive, high temperature and high pressure technology, applied in the direction of displaying liquid level indicators through pressure measurement, can solve the problems of inability to use, reduce the strength of the level gauge, and not suitable for use in flammable and explosive environments, and achieve high reliability , Improve the effect of reliability and applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

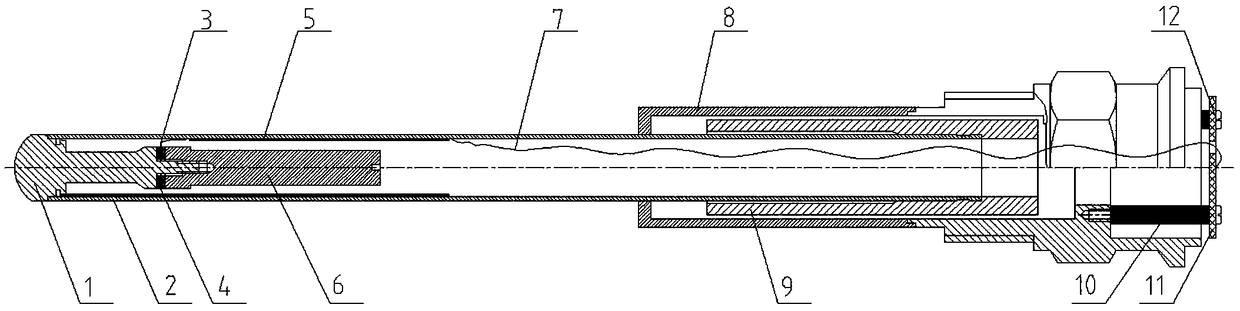

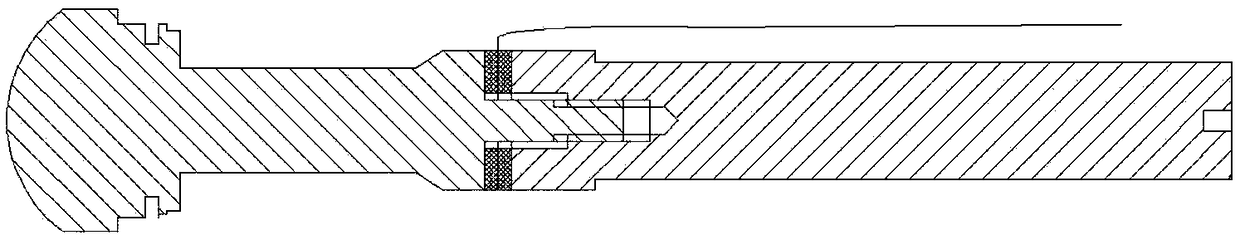

[0029] A vibrating material level switch suitable for high temperature, high pressure, flammable and explosive environments, including: vibrating head 1, vibrating rod 2, lead electrode 3, piezoelectric ceramics 4, pressing copper sheet 5, pressing copper column 6, Electrode lead wire 7, installation base 8, vibration rod copper sleeve 9, support copper column 10, transfer circuit board 11, compression screw 12;

[0030] The material of the compressed copper column 6 is brass, and its upper end surface is in the form of a slotted screw, so as to facilitate fastening with a screwdriver; its lower end surface is a smooth plane as large as the piezoelectric ceramic 4; With internal threads, it cooperates with the screw on the rear end of the vibrating head 1 to fasten the piezoelectric ceramic 4 between the compressed copper column 6 and the vibrating head 1 to achieve a tight fit; the lead electrode 3 is a circular copper sheet with an opening in the middle , which is located in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com