Computer nixie tube packaging device

A packaging device, digital tube technology, applied in packaging recycling, transportation and packaging, conveyor objects, etc., can solve the problems of dust removal, increase labor intensity, and digital tube sticking and falling off, and achieve the effect of ensuring cleanliness and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

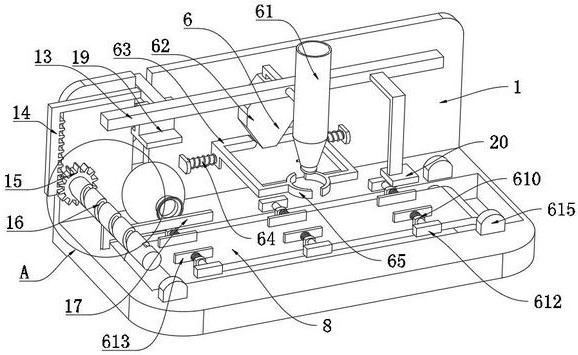

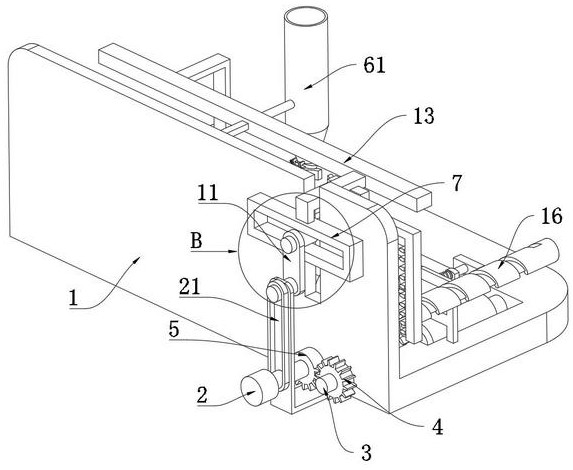

[0037] see figure 1 and image 3 and Figure 5, including the base plate 1, the rear end surface of the base plate 1 is fixedly connected with the drive motor 2 through the mounting plate 21, the output shaft of the drive motor 2 is fixedly connected with the half gear 5 through one end of the mounting plate 21, and the inner cavity wall of the base plate 1 is symmetrically rotated and connected with a Transmission shaft 3, a conveyor belt 8 is connected to the outer wall of the transmission shaft 3, and a gear 4 is fixedly connected to one end of the transmission shaft 3 through the rear end surface of the base plate 1. Mechanism 6, the rear end surface of the base plate 1 is slidably connected with the sliding frame 7 through the sliding rod 13, the rear end surface of the mounting plate 21 is connected with the support shaft 9 through rotation, and the outer wall of the output shaft of the drive motor 2 is connected with the support shaft 9 through the belt 10. The front ...

Embodiment 2

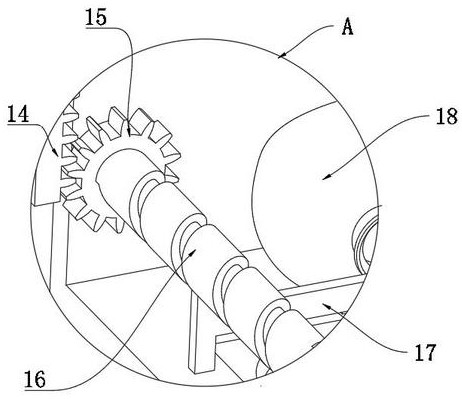

[0040] see Figure 1 to Figure 2 , the left side wall of the sliding rod 13 is fixedly connected with the rack 14, the front end surface of the base plate 1 is rotatably connected with a spiral groove rod 16, and the groove plate of the spiral groove rod 16 is slidably connected with the cleaning brush plate 17 through the slider, and the spiral groove rod 16 The outer wall of the base plate 1 is fixedly connected with a gear ring 15, the gear ring 15 is engaged with the rack 14, the cleaning brush plate 17 is slidingly connected with the upper end surface of the base plate 1, and the lower end surface of the sliding rod 13 is fixedly connected with a pressure rod 19.

[0041] During operation, through the cooperation of the rack 14, the ring gear 15, the spiral groove rod 16, and the cleaning brush plate 17, when the sliding rod 13 descends, the rack 14 will be driven to descend synchronously, and the gear ring 15 will be engaged to drive the spiral groove rod 16 to rotate. W...

Embodiment 3

[0043] see figure 1 and Image 6 and Figure 7 and Figure 8 , the extrusion limit mechanism 6 includes a rubber tube 61 and a diamond-shaped block 62. The front end surface of the sliding rod 13 is fixedly connected with a rubber tube 61, and the lower end surface of the sliding rod 13 is fixedly connected with a diamond-shaped block 62. The front end surface of the base plate 1 is symmetrically slidingly connected with The guide rod 63, one end of the guide rod 63 close to each other is attached to the outer wall of the diamond block 62, the front end surface of the base plate 1 is fixedly connected with the outer wall of the guide rod 63 through the spring telescopic rod 64, and the two guide rods 63 are fixedly connected to each other at one end of the guide rod 63 close to each other. Squeeze plate 65, the outer wall of the rubber tube 61 close to the lower part is symmetrically and fixedly connected with a convex block 67, the side wall of the convex block 67 is rotata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com