Piezoelectric element

A piezoelectric element and piezoelectric layer technology, which is applied in electrical elements, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., can solve the complex structure of wire-shaped piezoelectric elements and difficult to use piezoelectric elements , high manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, the piezoelectric element of the present invention will be described in detail based on the drawings.

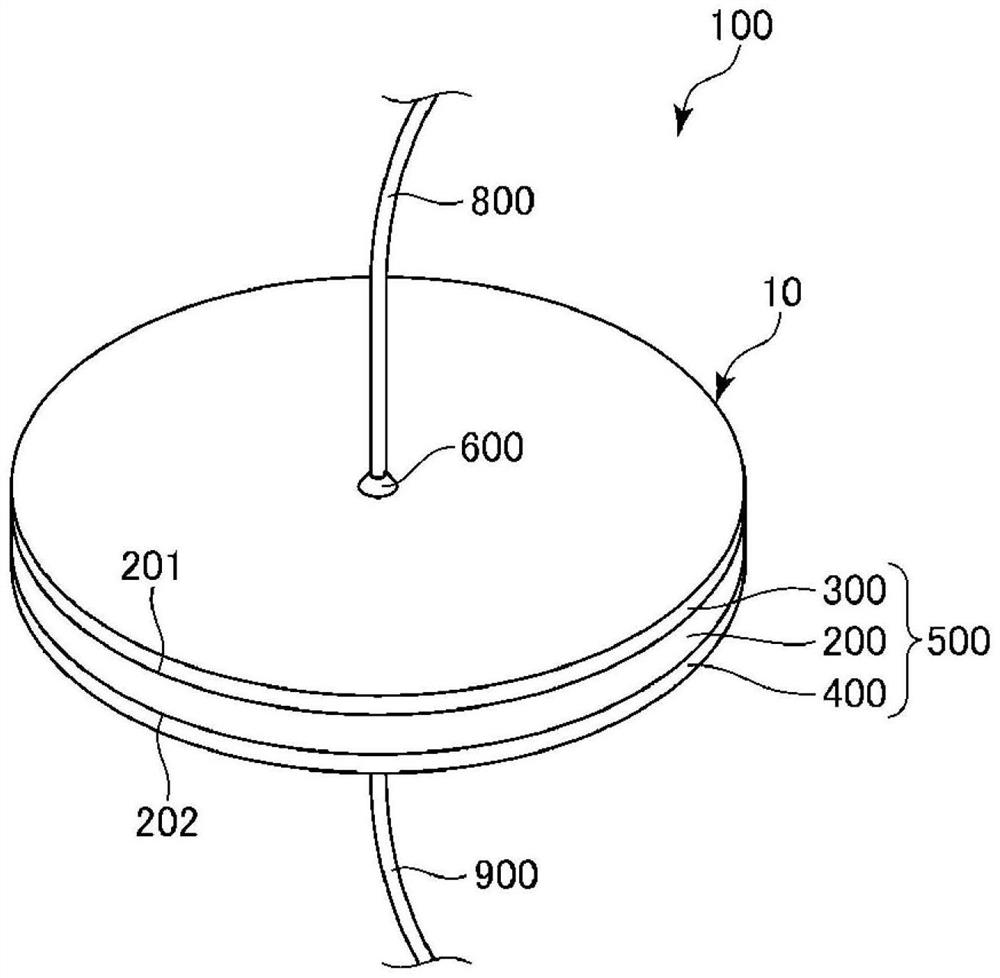

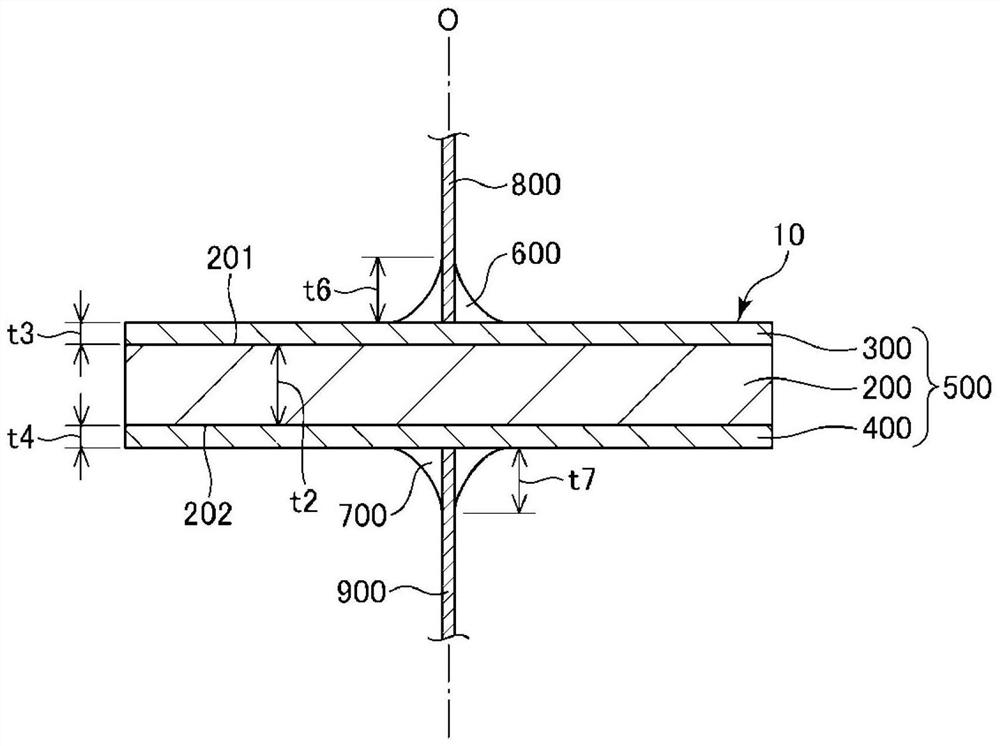

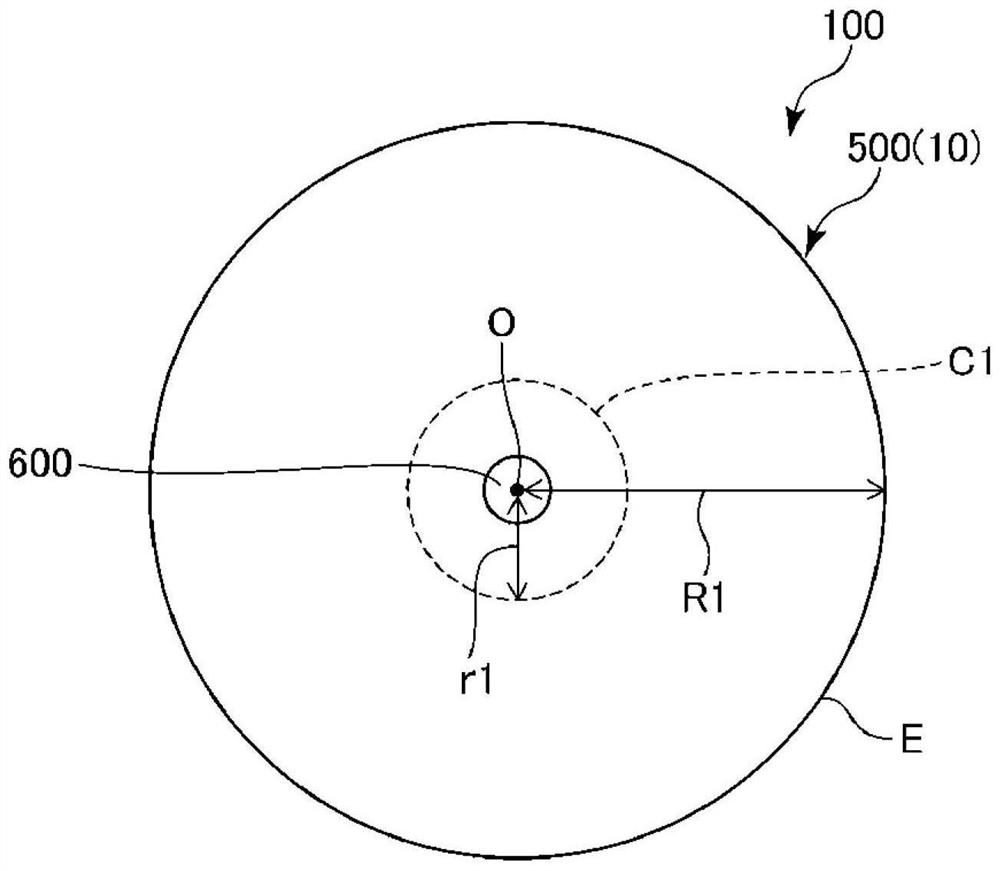

[0021] figure 1 It is a perspective view showing the piezoelectric element according to the embodiment. figure 2 Yes figure 1 Cross-sectional view of the piezoelectric element shown. image 3 Yes figure 1 Top view of the piezoelectric element shown.

[0022] 1. Piezoelectric element

[0023] figure 1 as well as figure 2 The illustrated piezoelectric element 100 includes a laminate 500 including a piezoelectric layer 200 , a first electrode layer 300 , and a second electrode layer 400 . The piezoelectric layer 200 has a first surface 201 and a second surface 202 having a front-back relationship with each other. The first electrode layer 300 is provided on the first surface 201 of the piezoelectric layer 200 . The second electrode layer 400 is provided on the second surface 202 of the piezoelectric layer 200 .

[0024] In addition, the piezoelec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com