Equal channel angular extruding, twisting and deforming mold for large plastic forming process

A technology of equal-diameter angle extrusion and twisting and forming process, applied in the direction of metal extrusion dies, etc., can solve the problems of uneven deformation and small amount of deformation in a single pass, so as to improve the uniformity of deformation, improve material properties, and improve the yield of finished products. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

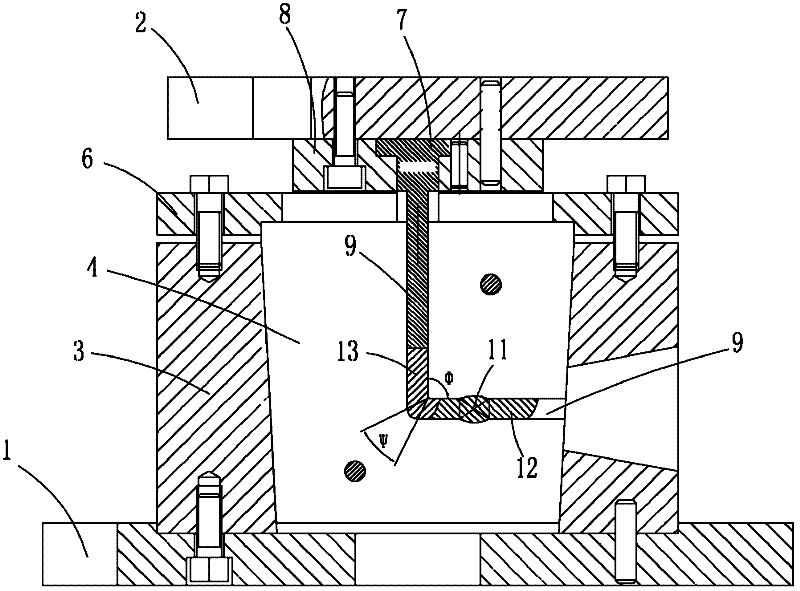

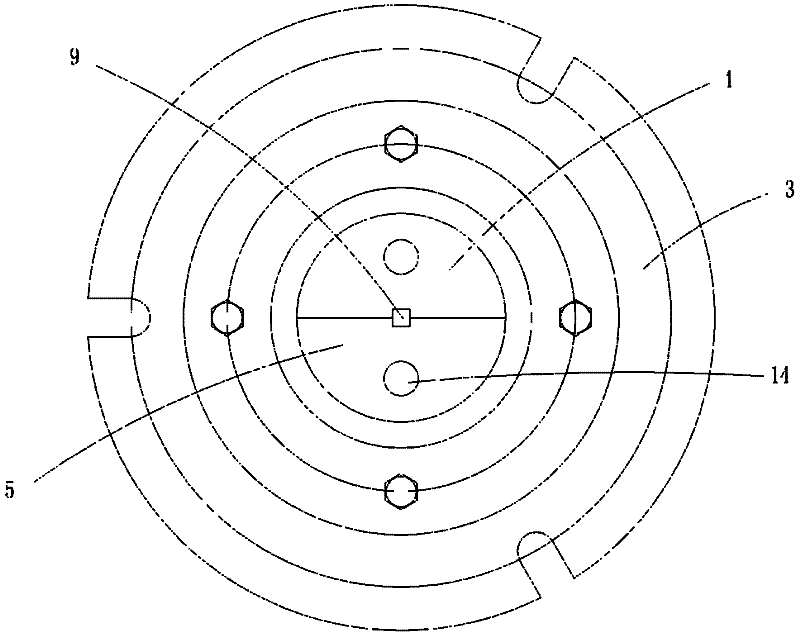

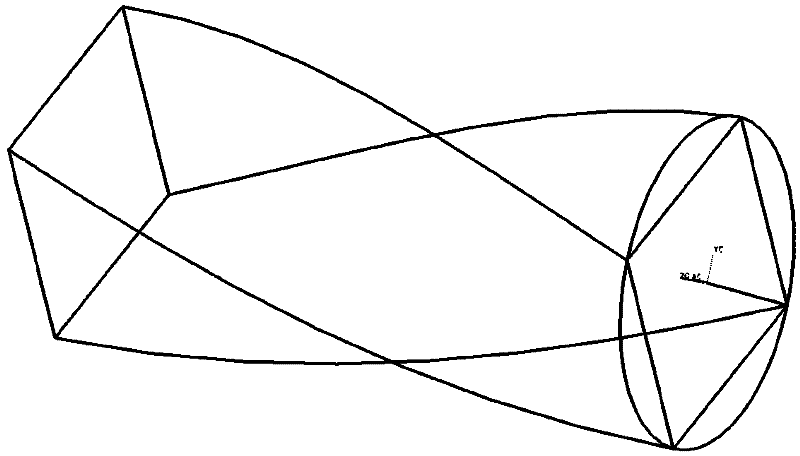

[0029] see figure 1 , figure 2 , torsion deformation mold, is provided with punch 7 and die, die is made up of die one 4 and die two 5, and die one 4 and die two 5 are two semi-cylindrical mating with channel grooves , connected as a whole by bolts, an inlet channel 9 and an outlet channel 10 communicating with the corner of the inlet channel 9 are arranged in the die, the inlet channel 9 and the outlet channel 10 have the same cross section, the punch 7 and the inlet channel 9 With loose fit, a spiral channel 11 with the same cross-section as the outlet channel 10 is provided in the outlet channel 10 . The mold is also provided with a fixed cylinder 3 for loading into the die, the fixed cylinder 3 is a circular cylinder structure, the bottom of which is fixedly connected to the lower formwork base 1, and the lower formwork base 1 is fixedly connected to the lower workbench of the press by bolts; The die pressing plate 6 is arranged above the fixing cylinder, the die pressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com