High-vibration connector torsion reed and manufacturing method thereof

A manufacturing method and connector technology, which are applied in the manufacturing of contacts, devices for joining/disconnecting connecting components, contact components, etc., can solve the problems of poor contact, ablation, poor roundness of the spiral cylinder, etc. Separation, high commercial value, effect of increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

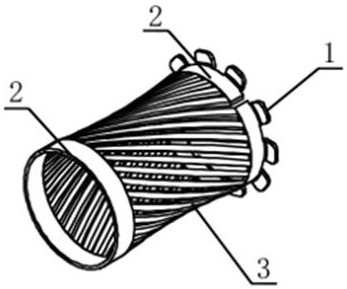

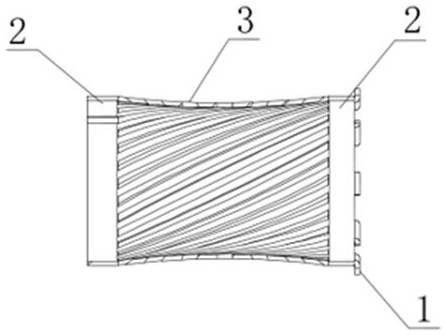

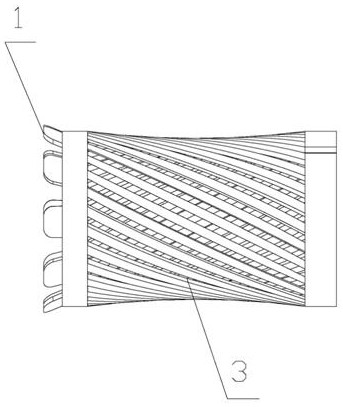

[0034] like Figure 1-3 , the socket contact piece of this embodiment is similar to the existing rotary body contact piece, including a sheet metal plate rolled into a metal tubular body, wherein a C-shaped pipe strip 2 has several bent positioning strips 1 and a middle part with Several helical bus bars 3 are formed by stamping or other methods to form a metal tubular body with two ends of the sheet metal plate close to each other, and are formed by turning and waisting along the central axis of the metal tubular body. The difference is that the C-shaped tube bar 2 Take the central axis of the metal tubular body as the center to extend outward to form a T-shaped or Y-shaped positioning strip 1, the angle is divided into 0°~89°, 0° is the angle of the metal tubular body when it is inside the socket body State, 89° takes the value below 90°. Generally, this is not used to make the angle of the device, but 45° is used. The effect of 89° is similar to that of 90°, but it is not e...

Embodiment 2

[0040] refer to Figure 4 and Figure 7 Shown: In this embodiment, the end face of the head of the jack body 5 and the positioning bar 1 are limited, and the end of the positioning bar is bent in the insertion direction to form a limiting groove.

[0041] Preferably, the end of the positioning bar 1 is placed horizontally with the central axis of the metal tubular body, and the included angle between the end of the positioning bar 1 and the central axis of the metal tubular body is 180°. In the hole body 5, press the metal or plastic cap 4 at a constant speed, and check that it is in place before riveting, so that the final connection becomes a seamless conductor. The cap 4 can prevent the metal tubular body from falling off during the process of pulling and inserting. And in the process of equipment operation, the metal tubular body is prevented from moving, and the defects such as poor vibration resistance, low current-carrying capacity, and ablation of similar contacts dur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com