Rotary linear mechanism for glassware forming machine

A glassware and forming machine technology, applied in the direction of blowing glass forming machine, blowing-glass forming machine, glass production, etc., can solve problems such as restricting the operation of cooling system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

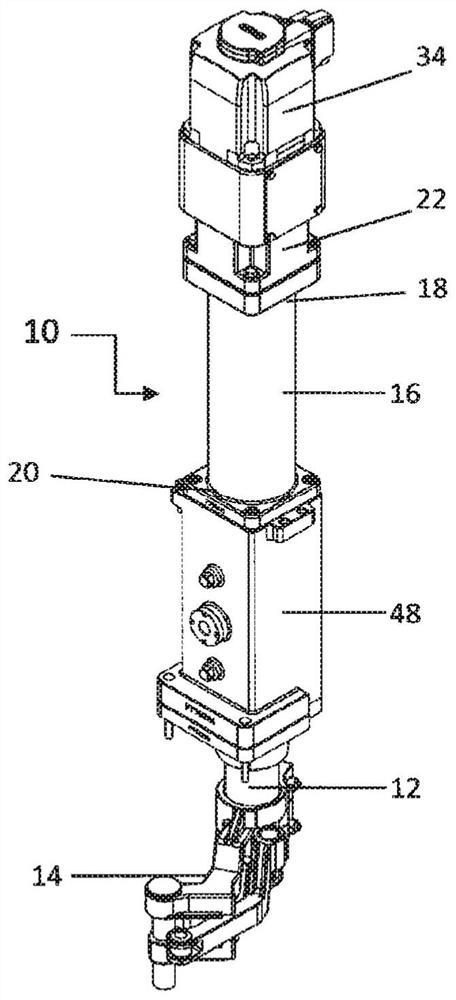

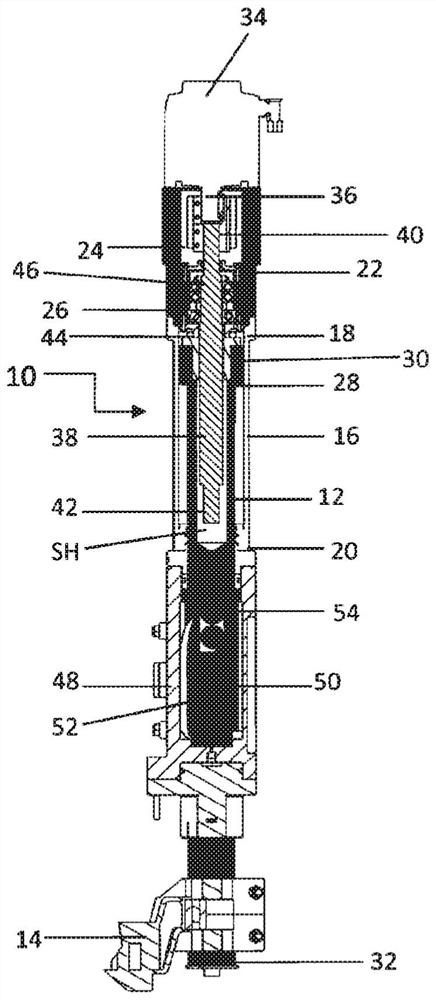

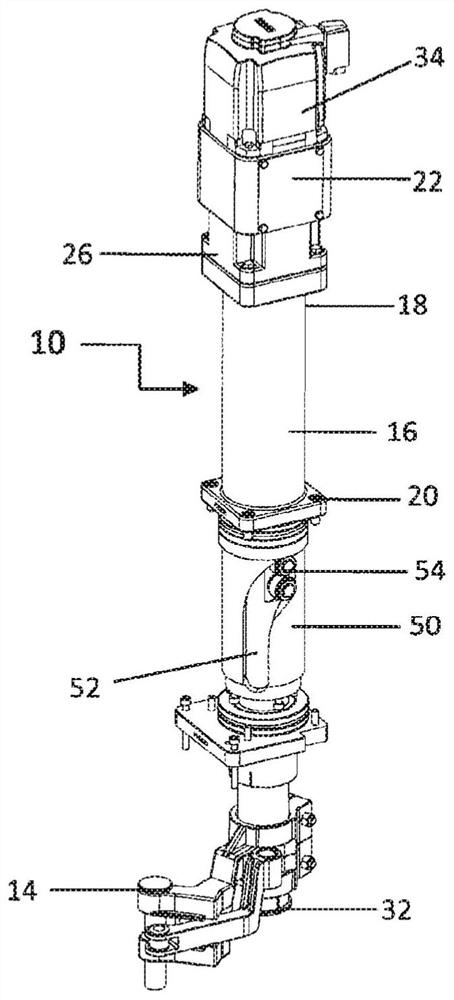

[0036] For a better understanding of the present invention, only the rotary linear mechanism 10 for the glassware forming machine will be described, without showing its coupling on the blowing head, baffle or funnel.

[0037] like figure 1As shown, a rotary linear mechanism 10 for a glassware former is primarily used to simultaneously move a shaft 12 with axial movement and an arm 14 with radial movement to the left or right. The shaft 12 is connected to the arm 14 . Arm 14 is a funnel holder arm, baffle arm or arm for the blowing head of the forming machine, which moves between an article forming position and a closed position. The shaft 12 has a hollow channel SH formed about half of the total length from the top to the shaft. It also includes a spring (not shown) located in the shaft 12 for safety purposes in the absence of electrical current, when the stored spring force is compressed, to enable the shaft to move to the up position and avoid any accident or shock.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com