Drying mechanism of floor brush and cleaning equipment thereof

A technology for cleaning equipment and drying, applied in dryers, drying gas layout, lighting and heating equipment, etc., can solve problems such as rising costs, erroneous startup of drying devices, and major safety risks, saving design, development and manufacturing costs. , The effect of reducing the probability of false start and shortening the drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0058] In order to realize the diversified functions of the base 2 , in particular, a charging function can be provided to the host part, so as to increase the battery life. The structural scheme adopted in this embodiment is: refer to Figure 4 to Figure 5 , the base 2 includes a tray 11 and a support frame 12 protruding from the tray 11, the support frame 12 is provided with a first charging assembly 13, and the first charging assembly 13 can be connected to an external power source ; The host shell 1 is provided with a battery assembly 32 and a second charging assembly 14, and the second charging assembly 14 is connected to the battery assembly 32; when the host shell 1 is placed on the base 2 , the first charging assembly 13 and the second charging assembly 14 are electrically connected to charge the battery assembly 32 in the host housing 1 .

[0059] The structure of the above-mentioned charging portion is substantially the same as the charging structure in the prior ar...

Embodiment 3

[0061] Since the base 2 is provided with the first charging assembly 13, when the base 2 is powered on and the host housing 1 is not placed, there is a certain risk if the first charging assembly 13 is exposed to the outside, and the safety standard cannot be met. At the same time, the first charging assembly 13 itself is also easily damaged by external impact.

[0062] Therefore, on the basis of the second embodiment, this embodiment adds a protection structure, which is as follows: refer to Figure 4 , the support frame 12 is also provided with a baffle assembly 15, the baffle assembly 15 has an open position state and a blocking position state. The specific situation in use is: when the host housing 1 is placed on the base 2, the baffle assembly 15 is switched to the open position to form a docking opening 16, so as to realize the first charging assembly 13 and the second charging assembly 15. The docking of the charging assembly 14 ; when the host housing 1 leaves the bas...

Embodiment 4

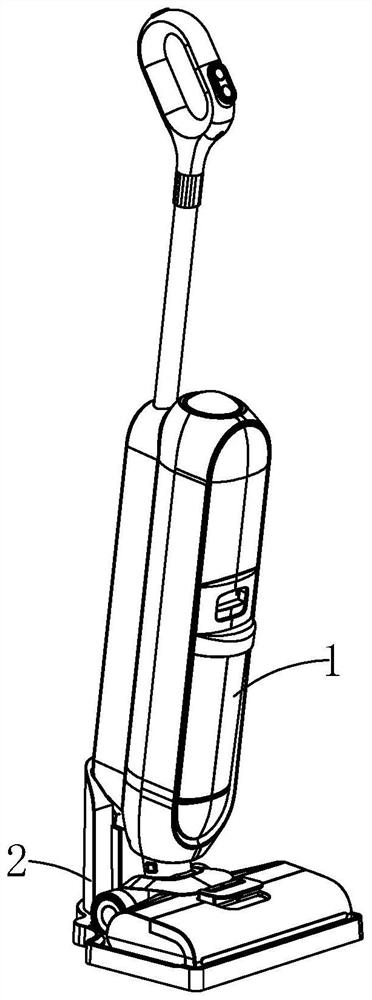

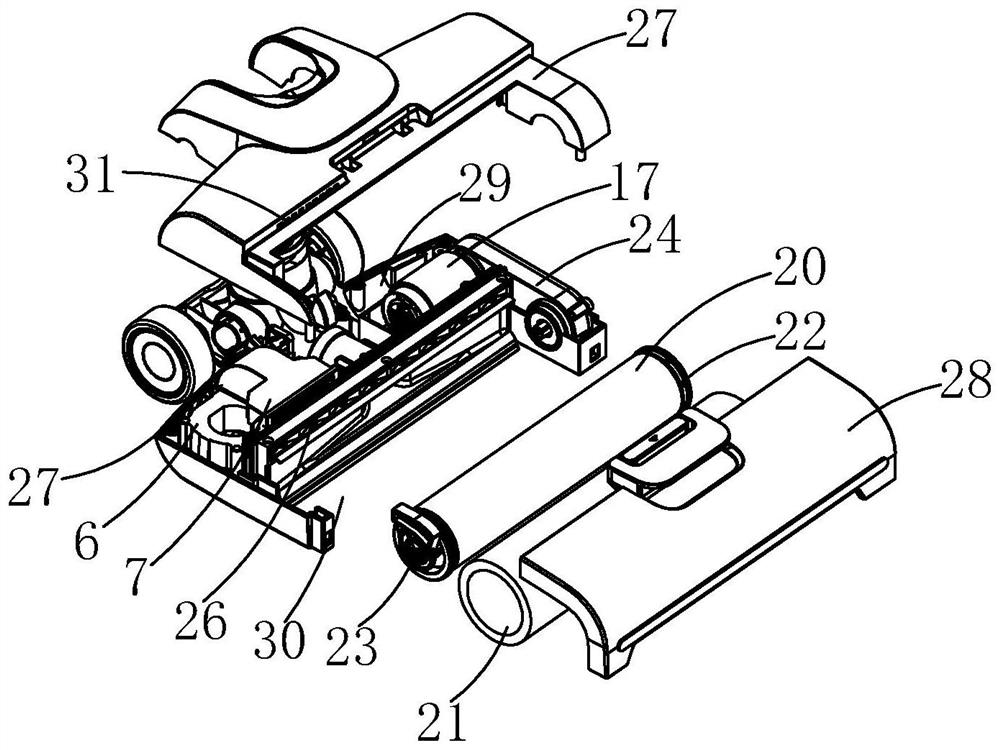

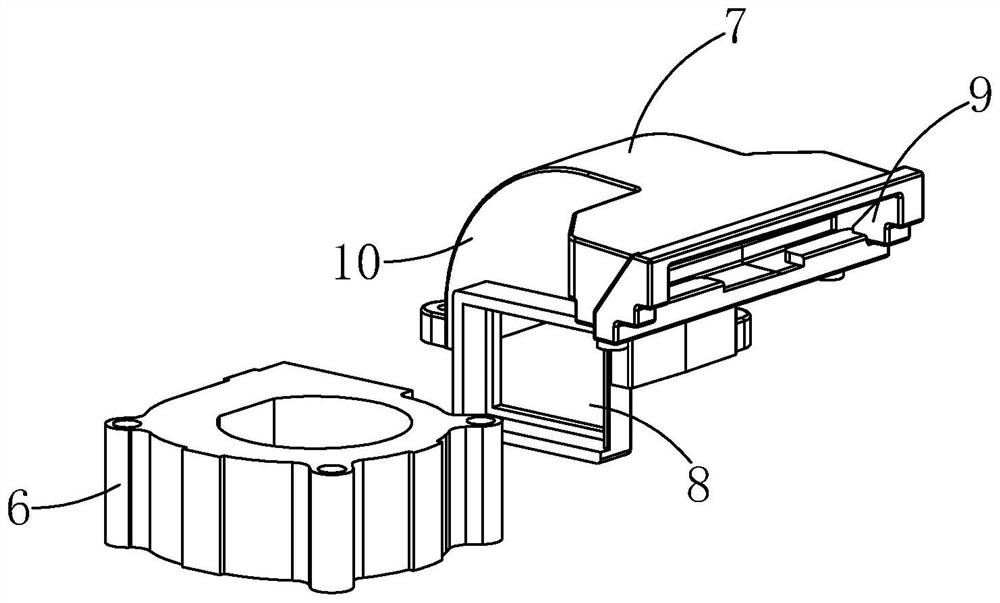

[0064] refer to Figure 1 to Figure 11 , the present invention also provides a cleaning device, including the drying mechanism of the floor brush mentioned above; also includes a driving mechanism, which acts on the roller brush assembly 3 so that the roller brush assembly 3 can be relative to the main casing. The body 1 rotates; when in use, the drive mechanism is turned on, so that the roller brush assembly 3 rotates continuously to clean the ground more effectively. At the same time, when the air-drying mechanism is running, the roller brush assembly 3 can also be operated by the driving mechanism at the same time, so as to further improve the overall drying effect of the roller brush assembly 3 .

[0065] In a conventional product, the rolling brush assembly 3 is in the front, and the driving mechanism is behind, and the driving mechanism drives the rolling brush assembly 3 to rotate through a transmission mechanism on one side. However, it has certain defects. For exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com