Driving control system and method for independent electric drive loading machine additionally provided with clutch

A drive control and loader technology, applied in the field of shoveling construction machinery, can solve problems such as waste of energy, maintenance difficulties, and energy waste, and achieve the effects of reducing parasitic power, improving use efficiency, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The present invention will be described in detail below in conjunction with the accompanying drawings and the embodiments, but those skilled in the art should know that the following embodiments are not the only limitations to the technical solutions of the present invention, and any work done under the spirit of the technical solutions of the present invention Equivalent transformation or modification shall be regarded as belonging to the protection scope of the present invention.

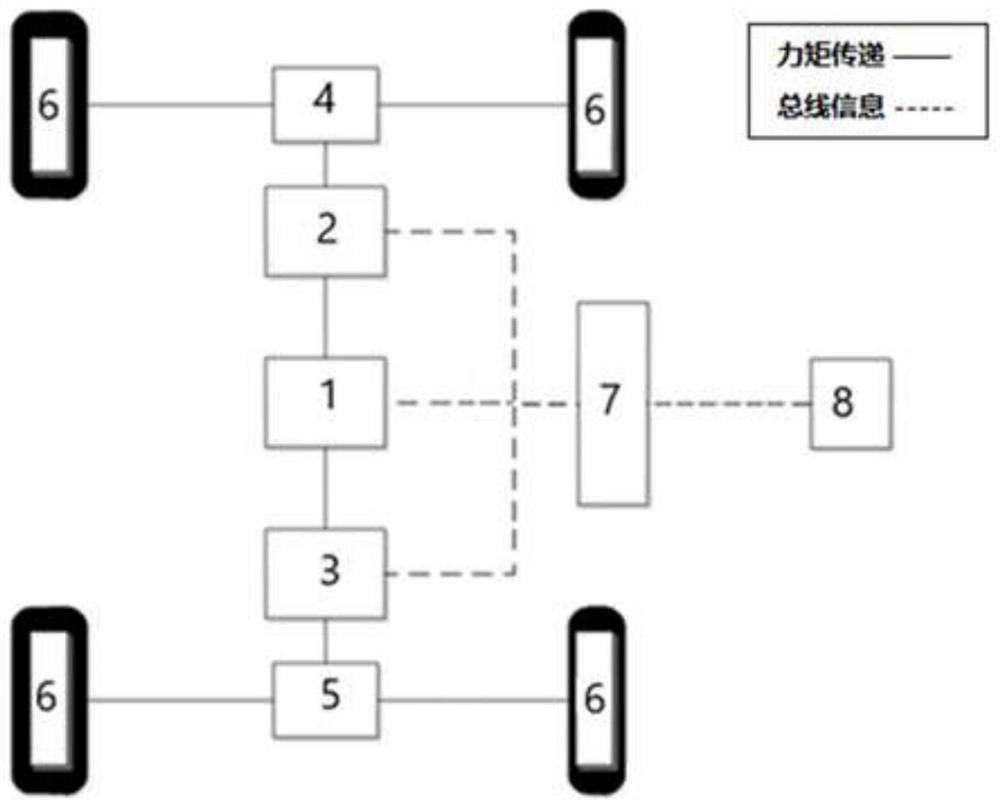

[0080] The invention provides a drive control system of a loader. The system is to install motors on the front and rear axles of the loader to drive the front and rear axles independently, and install a main reducer on the front and rear axles respectively, and install a wheel side reducer on the wheels. A new configuration of adding a clutch device between the two motors to increase the transmission ratio to meet the driving force requirements of the loader under shovelling conditions.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com