Scaffold for lining defect renovation construction in operation tunnel

A scaffolding and lining technology, applied in tunnel lining, scaffolding accessories, scaffolding connection, etc., can solve the problems of cumbersome procedures, increased construction cost, shaking, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

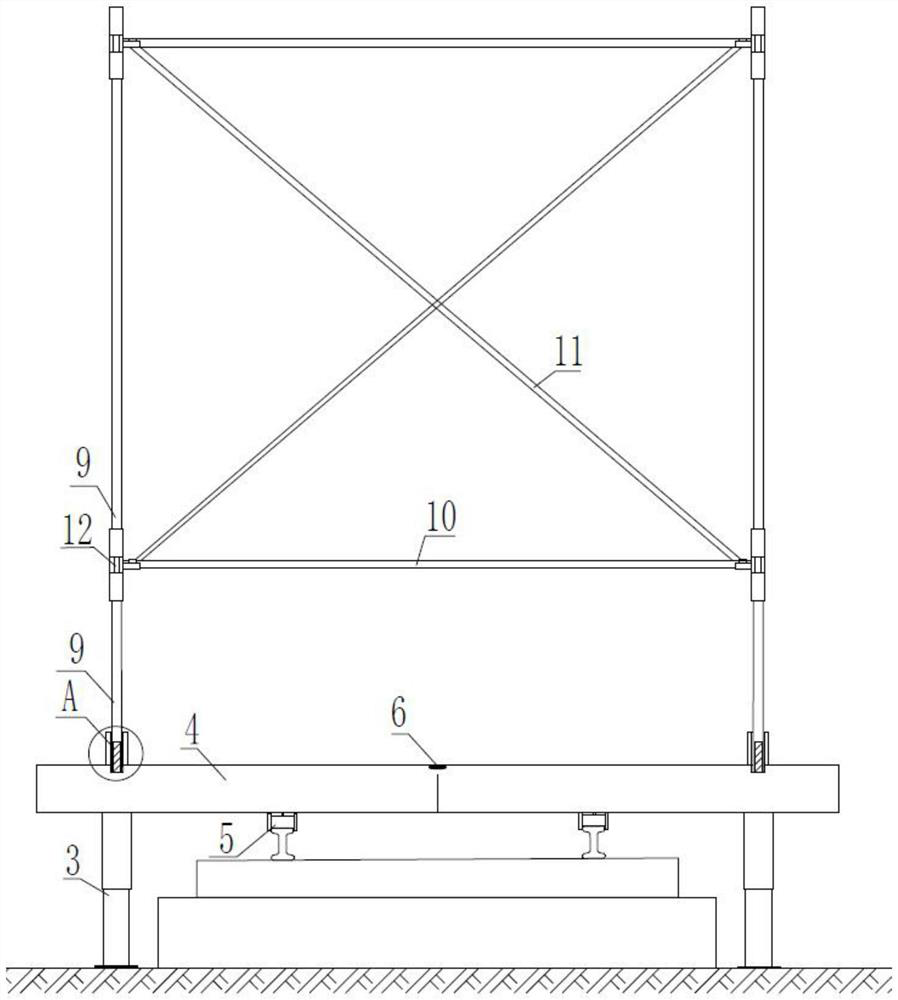

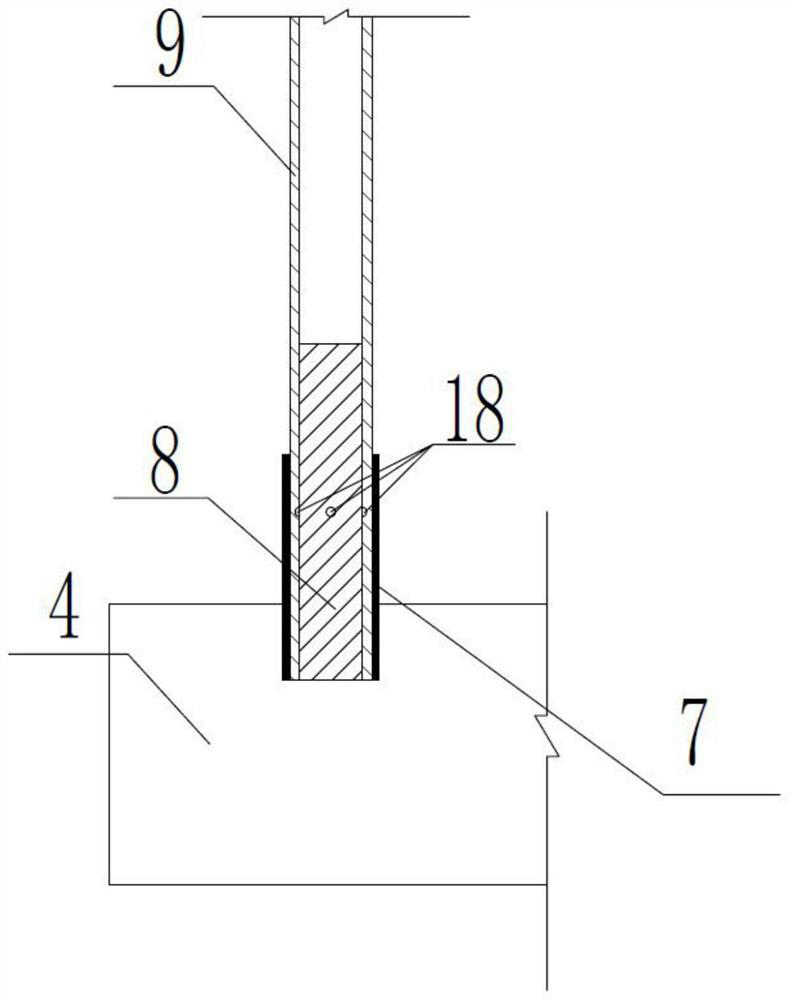

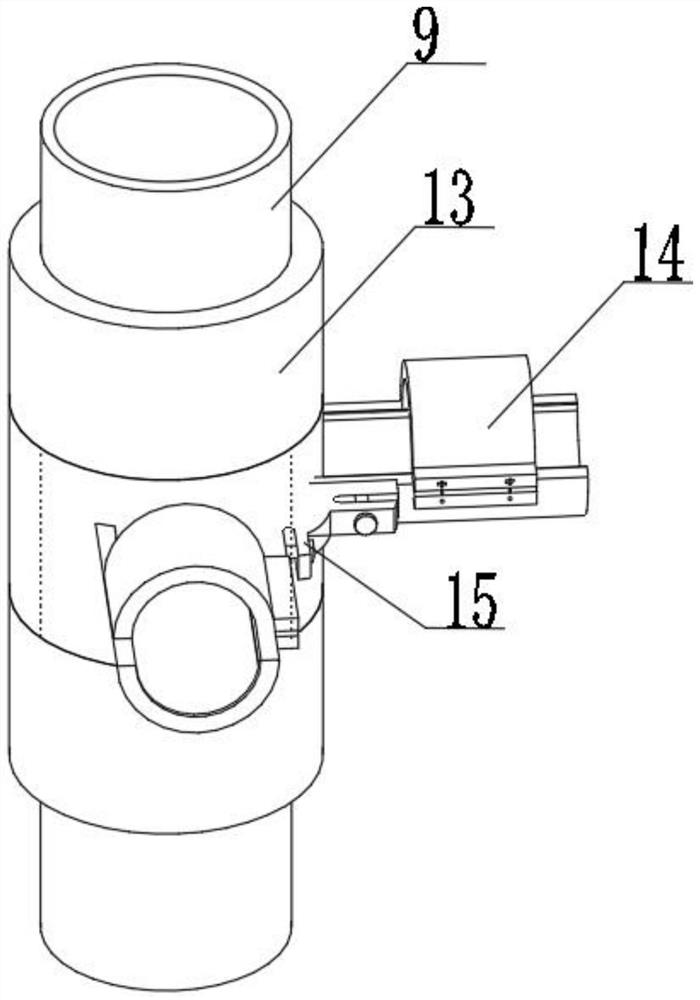

[0043] Refer to the attached Figure 1-17 , a scaffold for the construction of lining defect remediation in an operating tunnel, comprising a hydraulic cylinder 3, a scaffold pedestal 4, a vertical rod 9, a horizontal rod 10, a diagonal brace 11 and a three-dimensional connection mechanism 12, the hydraulic cylinder 3 is fixedly arranged on the scaffold pedestal 4 The lower end surface of the hydraulic cylinder 3 includes a cylinder body 301 and a piston rod 302. The upper end surface of the piston rod 302 is fixedly connected to the lower end surface of the scaffolding base 4, and the bottom surface of the cylinder body 301 is fixedly provided with the base 1.

[0044] Hydraulic oil cylinders 3 are arranged to support the overall supporting scaffold, and a regulating valve is set on the oil inlet pipeline of hydraulic oil cylinders 3 to control the oil inlet speed so as to realize separate adjustment of the jacking speed of each hydraulic oil cylinder, so as to level the scaff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com