PDC rotary-cut composite drill bit and construction method thereof

A composite drill bit and drill pipe technology, applied in the direction of drill bits, earthwork drilling, drilling equipment, etc., can solve the problems of blocked water holes, lower drilling speed, higher pump pressure, etc., to reduce the probability of mud bags and avoid repeated drilling The effect of cutting, increasing the speed of upward movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]The present invention will be further described below with reference to the accompanying drawings and embodiments.

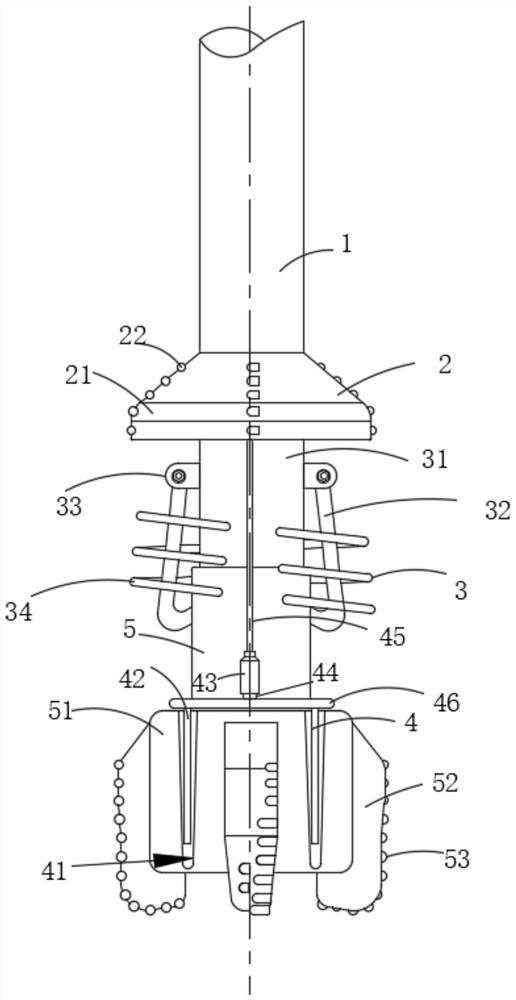

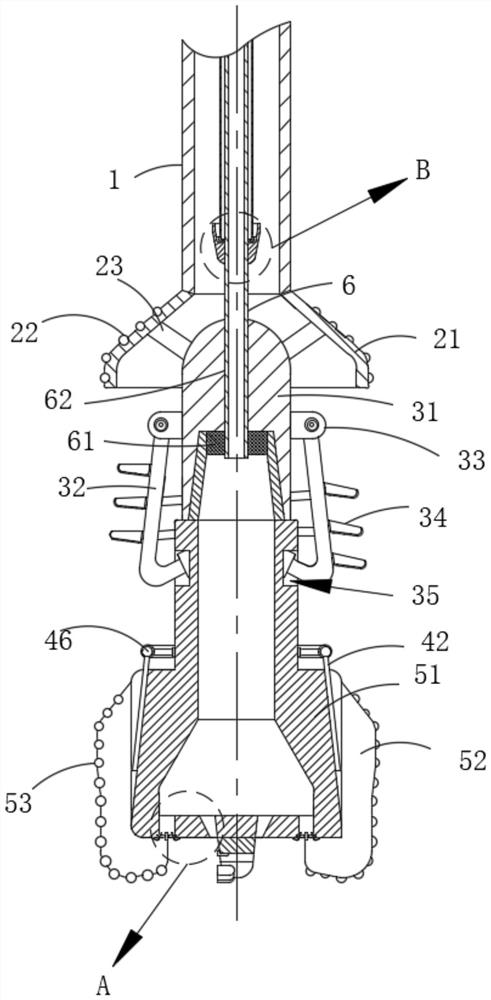

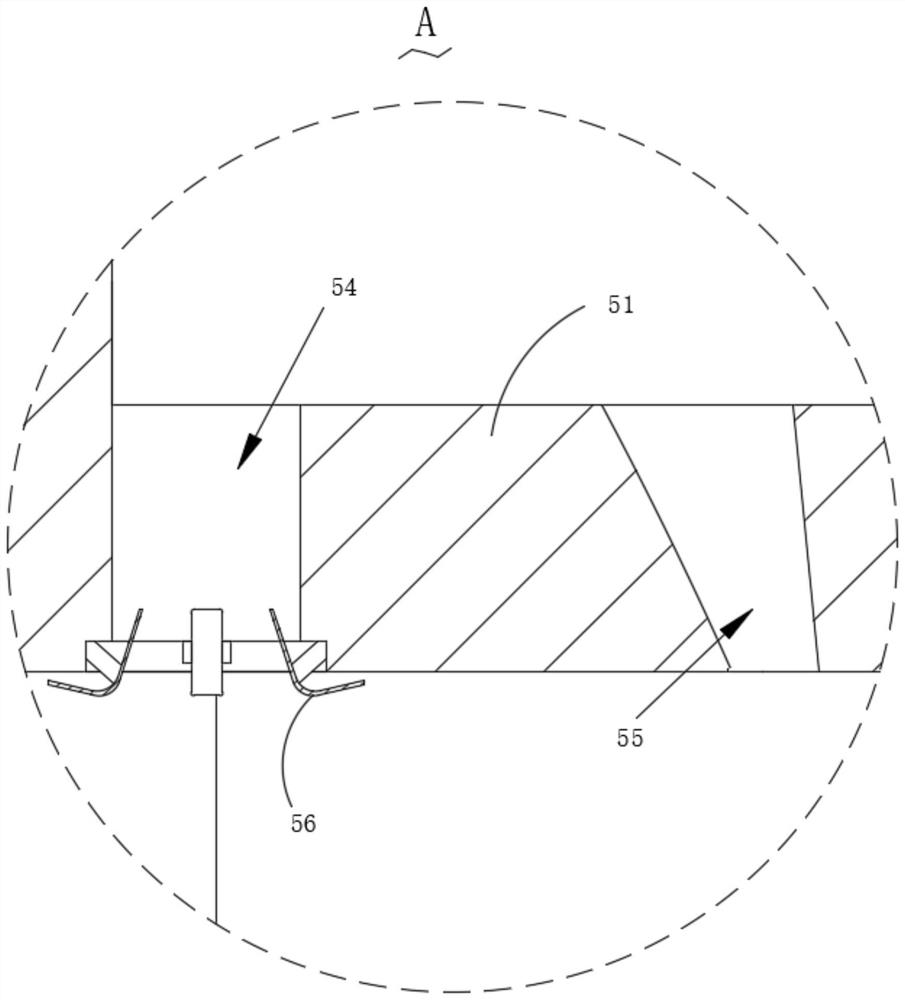

[0034] Please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 , the PDC rotary cutting compound drill bit includes: a drill rod 1; a feeding mechanism 2, which is fixed to the side wall of the drill rod 1; a fixing mechanism 3, which is fixedly connected to the feeding mechanism The bottom end of 2; the main body 5, the main body 5 includes a rigid body 51, a blade 52, a second cutting tooth 53, a first nozzle 54, a second nozzle 55 and a limit plate 56, the rigid body 51 is mounted on the fixed At one end of the mechanism 3, the side wall of the rigid body 51 is equidistantly connected to a plurality of the blades 52, and the side walls of the blades 52 are installed with a plurality of the second cutting teeth 53; the interior of the rigid body 51 is symmetrical The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com