Steam-cured static prefabrication production method of steel structure integrated assembled concrete wall material

A production method and concrete technology are applied in the field of steam curing-free static prefabrication of steel structure integrated prefabricated concrete wall materials, which can solve the problems of long constant temperature curing time, high consumption of heat energy, inability to maintain steady state and static state of concrete slurry, etc. To achieve the effect of ensuring strength and thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

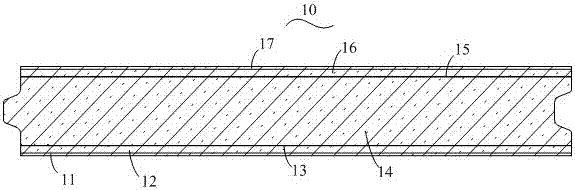

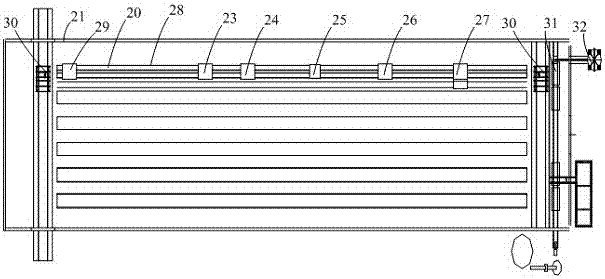

[0019] The steam-cured static prefabrication production method of steel structure integrated assembly type concrete wall material provided by the present invention ensures the strength and thermal insulation performance of the concrete wall material by setting a stable support platform and a molding mold corresponding to the length of the support platform. After the wall material reaches the curing time, it is cut according to the size required by the construction site to reduce the generation of leftovers. The production efficiency is improved by fixing the grid cloth on the forming mold as a whole, and the heating device is installed on the support platform to achieve energy saving effect. The following details are explained:

[0020] A steel structure integrated prefabricated concrete wall material steam-free static prefabrication production method, comprising the following steps:

[0021] Step S101, setting at least one stable carrying platform, and setting a heating devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com