Novel-structure heat dissipation bearing seat with anti-rotation function

A new structure and anti-rotation technology, which is applied in the direction of bearing cooling, shaft and bearing, bearing components, etc., can solve the problems of unrestricted bearing rotation in one direction, weakening effect of circulating water, etc., and achieve the effect of preventing rotation and improving heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

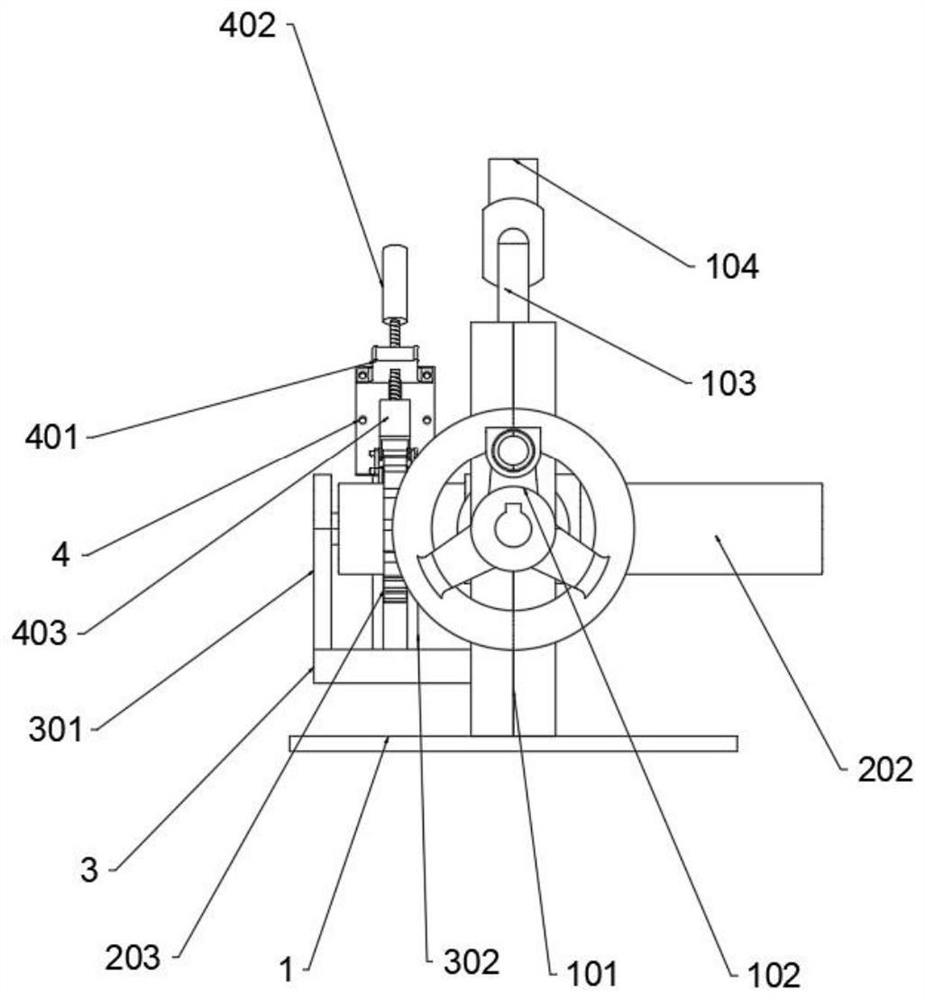

[0035] as attached figure 1 to the attached Figure 10 shown:

[0036]The present invention provides a new structure heat dissipation bearing seat with anti-rotation function, which includes: a base 1; the middle position of the top of the base 1 is fixedly connected with the middle position of the bottom of the limit frame 101, the limit frame 101 and the base 1 together form a T-shape, the limit frame Slide rails are arranged at the upper and lower ends of the interior of the 101, a circulation pipe 103 is arranged at the inner position of the top end of the restriction frame 101, a circulation pump 104 is arranged at the middle position of the upper end of the circulation pipe 103, and a bearing bracket 2 is slidably connected to the inner middle position of the restriction frame 101. , a bearing body 201 is arranged at the inner middle position of the bearing bracket 2, a plunger 202 is rotatably connected to the inner middle position of the bearing body 201, a ratchet wh...

Embodiment 2

[0040] Based on the new structure heat dissipation bearing seat with anti-rotation function provided by the first embodiment, the bearing bracket 2 is put into use after the position is fixed. When adjusting the overall position of the bearing bracket 2, the position of the bearing bracket 2 needs to be disassembled and installed. In the case of inaccurate openings in the position where the bearing seat is installed, the normal installation of the bearing seat is affected, and the installation position needs to be re-drilled to improve the relative installation position;

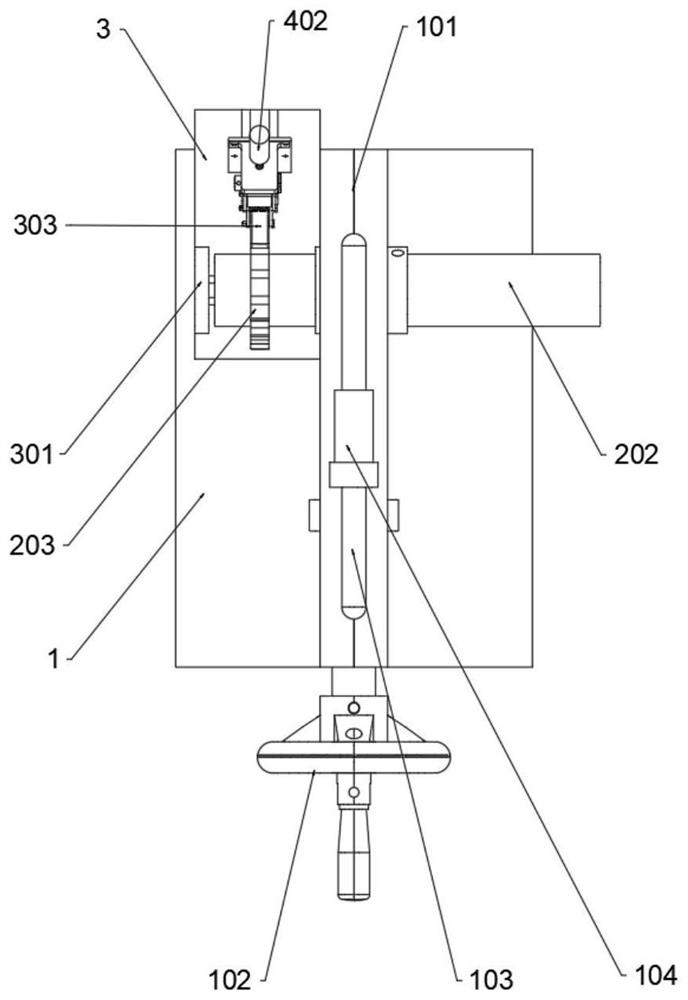

[0041] Furthermore, the new structure heat dissipation bearing seat with anti-rotation function includes: a limiting frame 101; an adjusting screw rod 102 is rotatably connected to the middle position of the front end of the limiting frame 101; Perforations are provided at the side positions, and the threaded holes at the front end of the bearing bracket 2 are rotatably connected with the rear end position of...

Embodiment 3

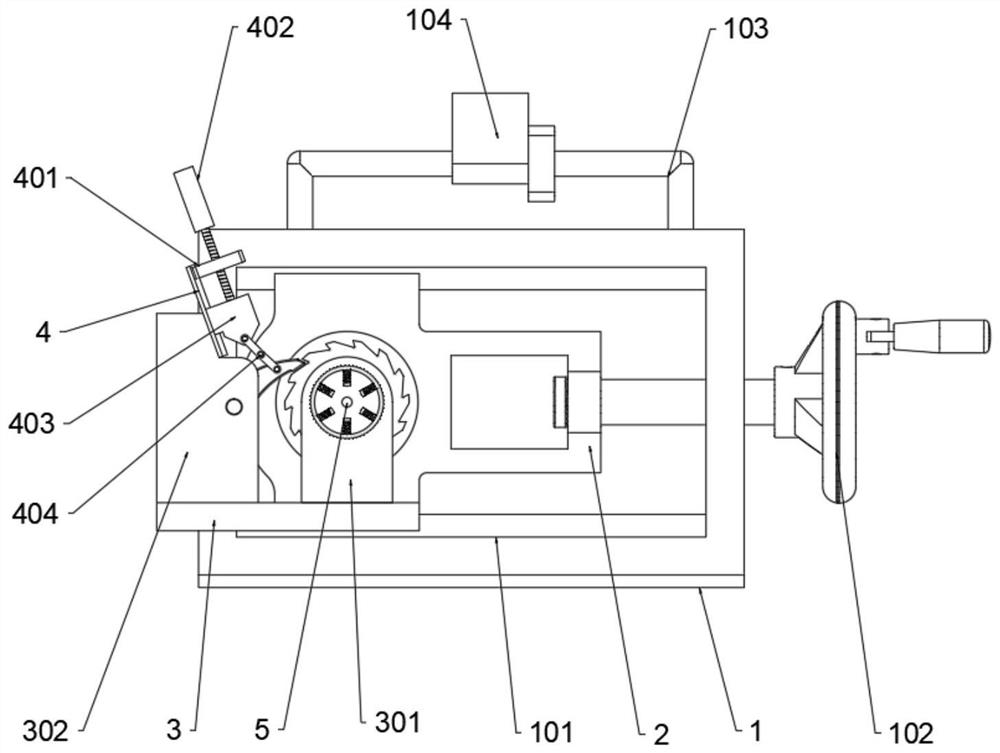

[0044] Based on the new structure heat dissipation bearing seat with anti-rotation function provided by the first embodiment, there is a situation of rotation when the bearing is put into use, so when the bearing is installed in the bearing seat and used, it will drive the rotating rod located in the bearing to have positive and negative The new structure heat dissipation bearing seat with anti-rotation function includes: an extension seat 3; a docking frame 302 is fixedly connected to the right rear end of the top end surface of the extension seat 3, and the docking bracket 302 is located at the rear end of the pawl 303. The upper position of the front end of the docking frame 302 is rotatably connected with a pawl 303 , and the front end position of the pawl 303 is engaged with the rear end position of the ratchet wheel 203 .

[0045] In addition, the top position of the docking frame 302 is provided with an inclined skateboard seat 4, the front end of the skateboard seat 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com