Material chemical preparation sampling analysis device

A sampling analysis and chemical technology, which is applied in the field of material chemistry, can solve the problems of inaccurate detection and analysis data, uneven heating of chemical materials, and reduce the efficiency of detection and analysis, so as to improve accuracy, automatically control heating time, and high work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In the following, only certain exemplary embodiments are briefly described. As those skilled in the art would realize, the described embodiments may be modified in various different ways, all without departing from the spirit or scope of the present invention. Accordingly, the drawings and description are to be regarded as illustrative in nature and not restrictive.

[0024] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

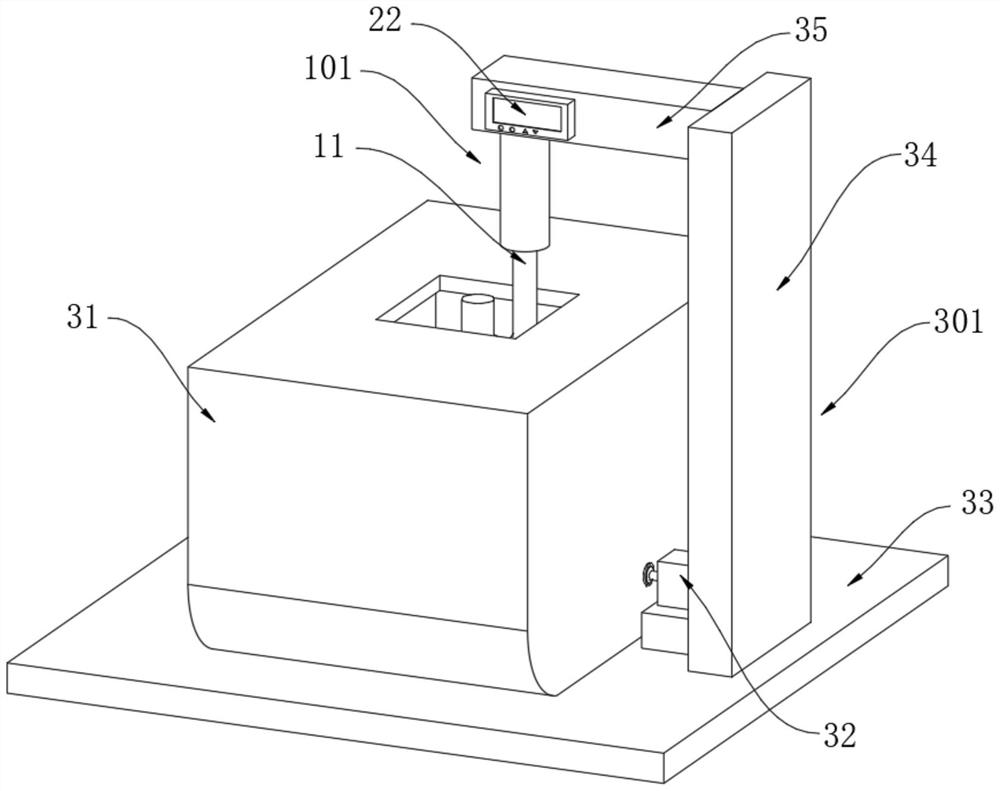

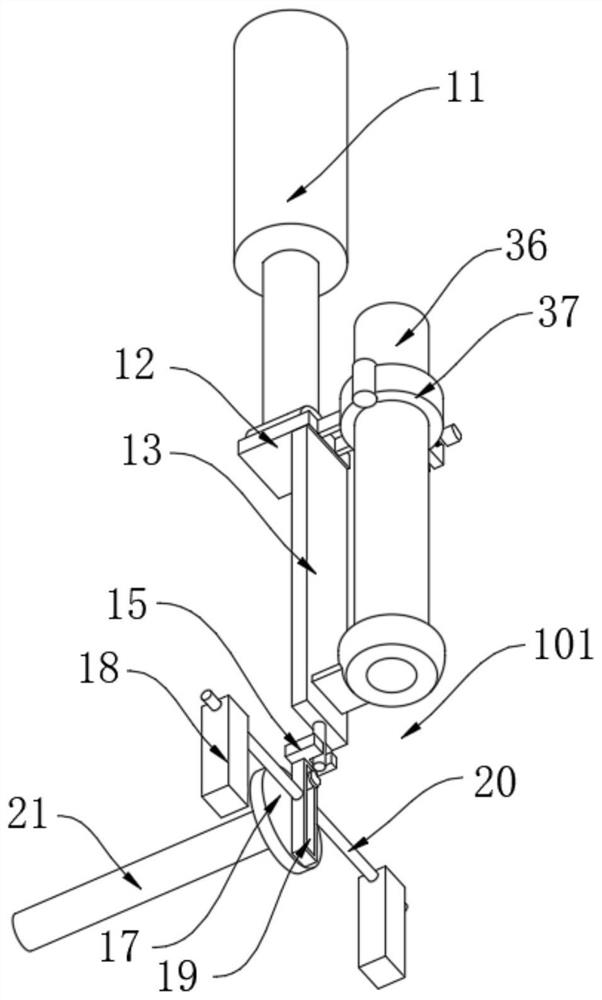

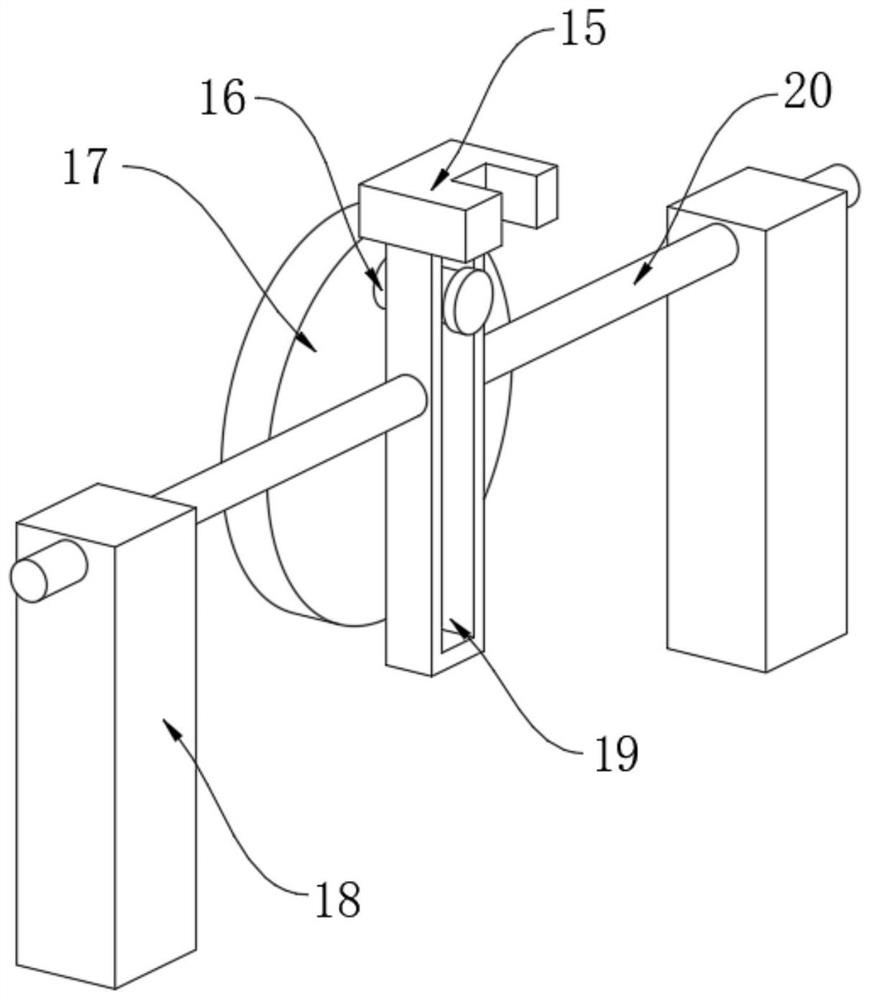

[0025] like Figure 1-4 As shown, the embodiment of the present invention provides a material chemical preparation sampling and analysis device, including a shaking assembly 101, and the shaking assembly 101 includes an electric telescopic rod 11, a fixed plate 12, a connecting plate 13, a fixed column 14, a U-shaped clamping block 15, connecting column 16, turntable 17, two fixed blocks 18, connecting frame 19, two sliding columns 20, rotating shaft 21 and time controller 22; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com