Non-linear modal calculation method of tire structure

A calculation method and nonlinear technology, applied in complex mathematical operations, design optimization/simulation, geometric CAD, etc., can solve problems such as increasing the difficulty of tire modal analysis calculations, and achieve the effect of a simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

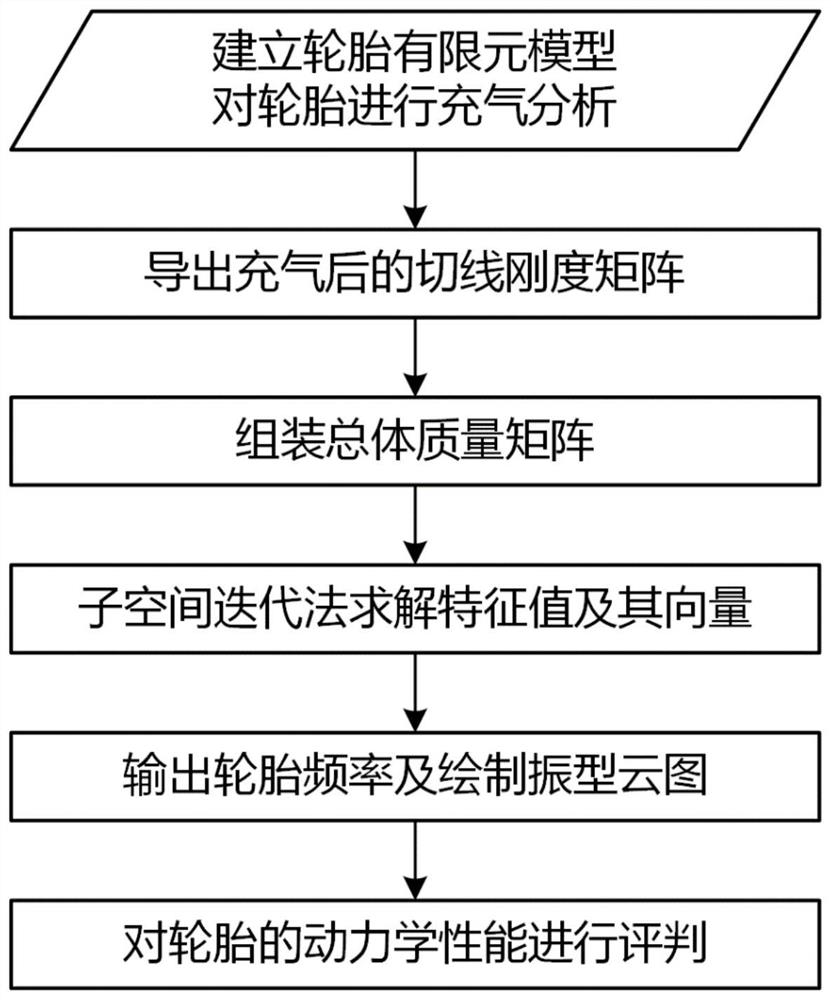

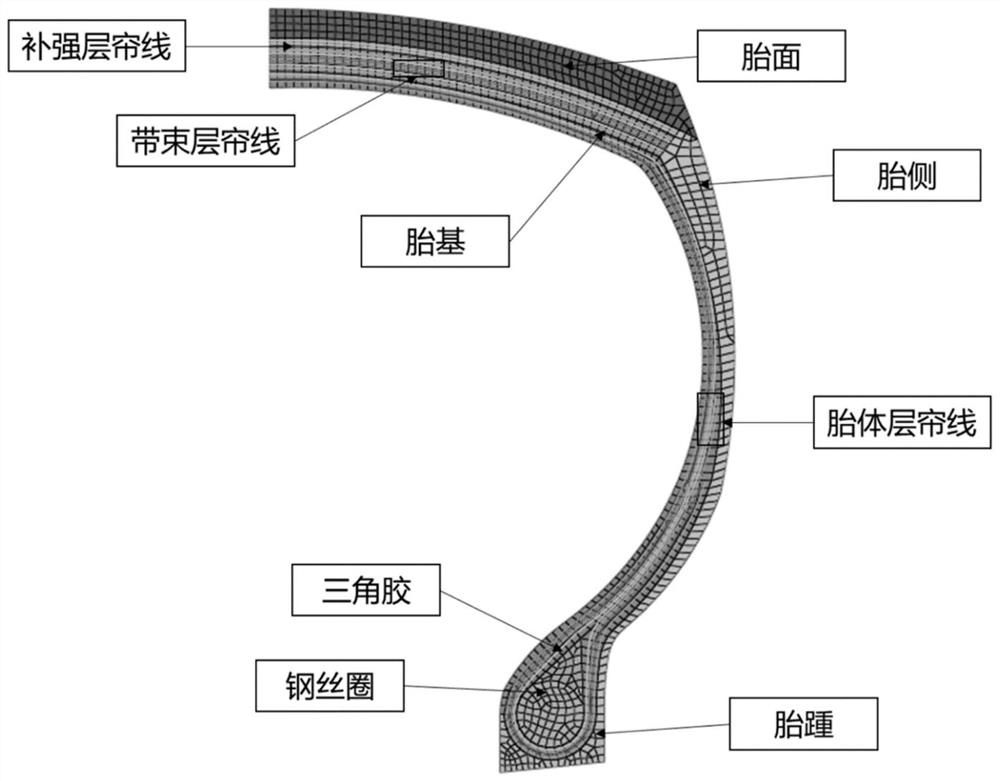

[0063] see figure 2 One of the model aircraft tires shown. image 3The distribution of individual components of tread, sidewall, carcass cords, heels, beaders, apex, base, belt cords, and reinforcement cords is given, where beaders and cords It is a linear elastic material, and its material parameters are shown in Table 1. Other components are isotropic superelastic rubber material. The Mooney-Rivlin constitutive model is used for the rubber material, and its material parameters are shown in Table 2. Among them, A 10 and A 01 is the material constant and K is the bulk modulus. In the tire finite element simulation, not only the material properties of the cords need to be determined, but also parameters such as the diameter of a single cord, the distance between adjacent cords, and the laying angle of the cords, which are listed in Table 3. List in detail. In the inflation analysis, the tire pressure is 0.96MPa, and the model has a total of 228,000 units, 268,000 nodes, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com