Soil throwing type ridging device

A soil throwing board and soil crushing technology, which is applied in planting methods, agricultural machinery and tools, and digging/covering ditches, etc., can solve the problems of inability to meet the needs of ridging, limited height of ridging, and easy overload of the throwing turntable. Work and other issues, to achieve the effect of reducing manual workload, high ridge efficiency, safe use and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

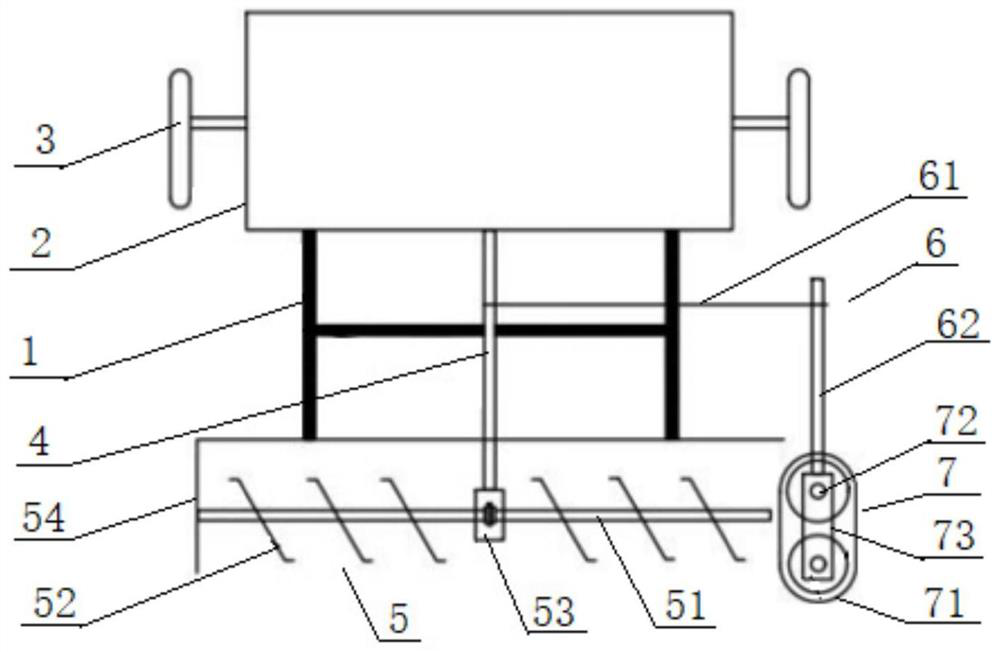

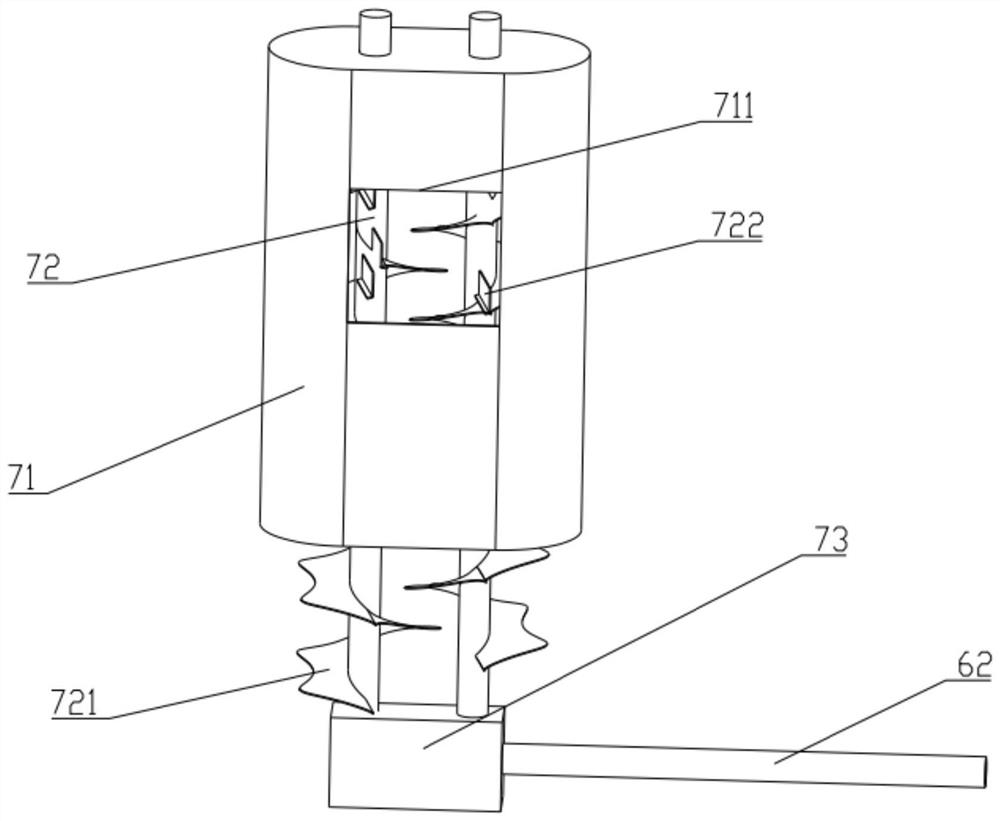

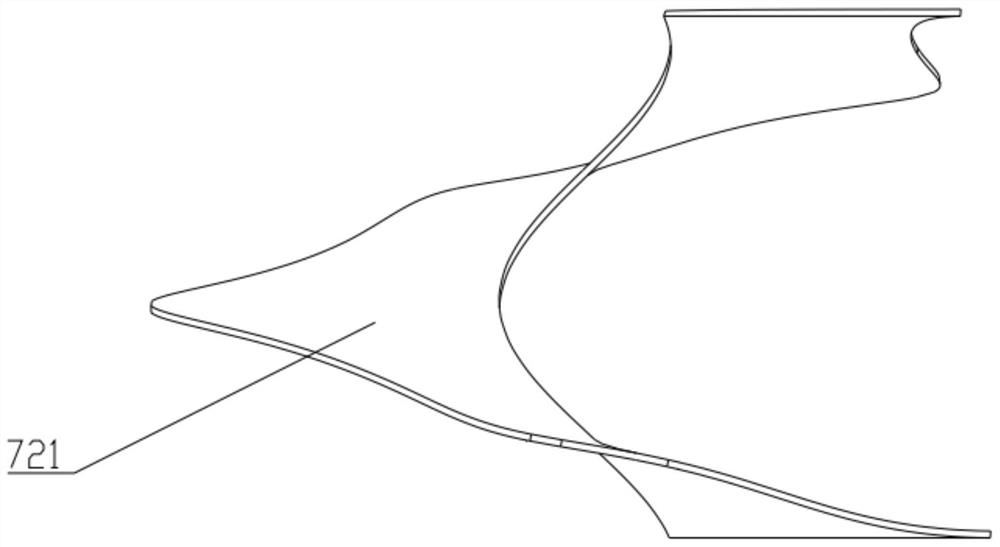

[0028] A soil throwing type ridge device, such as figure 1 , figure 2 As shown, it includes a frame 1, a power assembly 2, a soil breaking mechanism 5 and a soil throwing mechanism 7. The power assembly 2 is connected to the front of the frame 1, and the soil breaking mechanism 5 is connected to the rear of the frame 1. The soil mechanism 7 is located at the end of the soil crushing mechanism 5, and the soil crushing mechanism 5 and the soil throwing mechanism 7 are respectively connected with the output end of the power assembly 2; the output end of the power assembly 2 is connected with the traveling mechanism 3 for driving the ridge device The soil throwing mechanism 7 includes a fixed cover 71 and a number of screw augers 72. The fixed cover 71 is located at the end of the soil crushing mechanism 5, and the soil crushing mechanism 5 can transport the crushed soil to the bottom of the fixed cover 71. Several screw augers 72 are rotated and installed on Inside the fixed co...

Embodiment 2

[0035] This embodiment is similar to the first embodiment, the difference is that, as figure 1 As shown, the soil crushing mechanism 5 includes a cutter shaft 51 and a plurality of blades 52. The output shaft 4 is connected to the cutter shaft 51 through a first turbine box 53. A plurality of blades 52 are respectively fixed on the cutter shaft 51, and a plurality of blades 52 are in a spiral structure. Distribution, the fixed cover 71 is located on the side of one end of the cutter shaft 51 . During implementation, the power assembly 2 drives the output shaft 4 to rotate, and the first turbine box 53 makes the cutter shaft 51 rotate at a high speed. Broken, and because the blades 52 are distributed in a spiral structure, during the rotation of the blade shaft 51 , the blades 52 transport the crushed soil to one end of the blade shaft 51 and finally to the bottom of the fixed cover 71 .

[0036] like figure 1 As shown, a protective shell 54 is also included, and the frame 1 ...

Embodiment 3

[0038] This embodiment is similar to the second embodiment, the difference is that, as figure 1 As shown, several screw augers 72 are drivingly connected with the output shaft 4 through the transmission assembly 6 .

[0039] like figure 1 As shown, the transmission assembly 6 includes a transmission shaft 62, a belt 61, a first pulley and a second pulley connected by the belt 61. The first pulley and the second pulley are respectively coaxially connected with the output shaft 4 and the transmission shaft 62. The transmission shaft 62 Arranged in parallel with the output shaft 4 , the transmission shaft 62 is rotatably connected with the fixed cover 71 , and the transmission shaft 62 is connected with a plurality of screw augers 72 through a second turbine box 73 . During implementation, the power assembly 2 drives the output shaft 4 and the first pulley on it to rotate, drives the second pulley and the transmission shaft 62 to rotate through the belt 61, and drives a number o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com