Environment-friendly treatment equipment for flowback fluid of coal-bed gas well

A technology for environmental protection treatment and coalbed methane wells, which is applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve the problems of long waiting time and affect work efficiency, and achieve the effect of reducing sediment, improving effect and saving time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

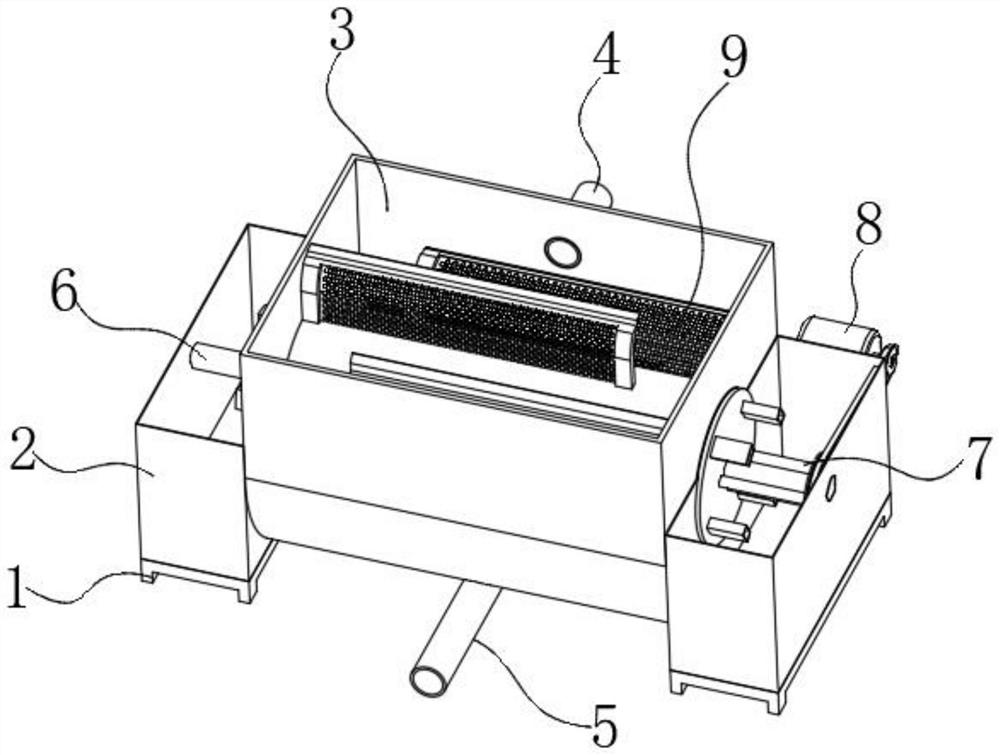

[0040] refer to Figures 1 to 4 , the present invention provides a technical solution: a coalbed methane well flowback fluid environmental protection treatment equipment, comprising:

[0041] Base 1, configured as two, is preset on the ground;

[0042] There are two sand collecting pools 2, which are respectively fixed on the upper end surfaces of the two bases 1;

[0043] The sand discharge bin 3 is fixed between the two described sand collecting tanks 2, and a liquid inlet 4 is provided on one side near the top, and a liquid outlet 5 is provided on the other side near the bottom, which are respectively used for and Valves are installed on the liquid inlet 4 and the liquid outlet 5 to control the in and out of the backflow;

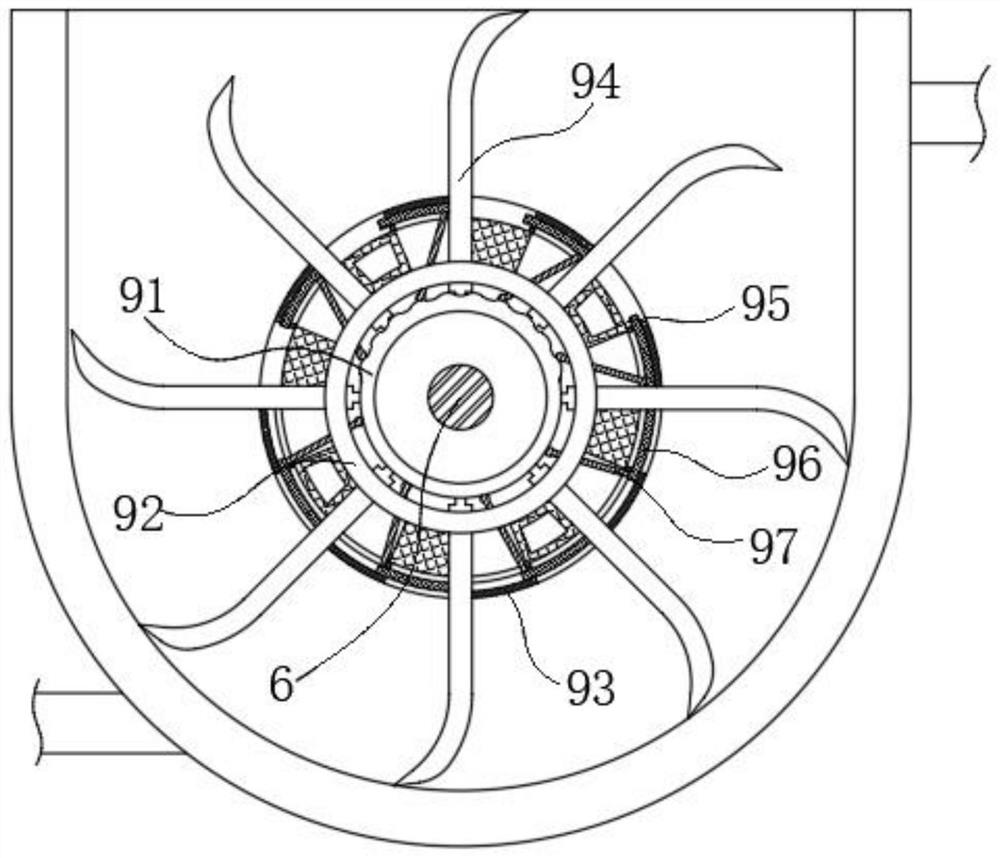

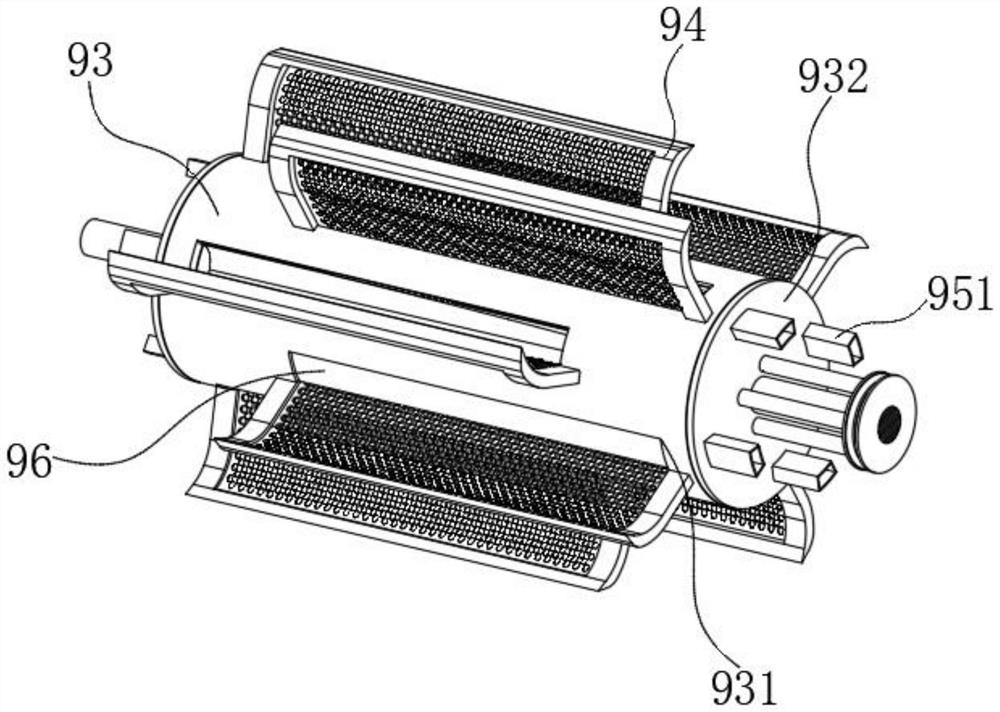

[0044] The fixed shaft 6 is fixed between the two described sand collecting pools 2, and it runs through the described sand discharging bin 3 and the sand collecting pool 2, and one end of which is located inside one of the described sand collecting po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com