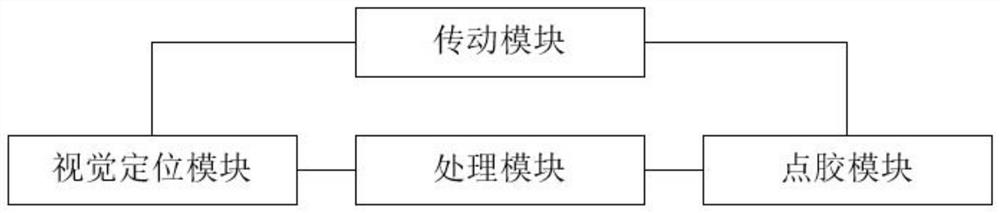

Automatic intelligent control dispensing machine system

A technology of intelligent control and dispensing machine, which is applied to devices and coatings that apply liquid to the surface. It can solve the problems of offset, inability to identify, inconsistent dispensing, and relying on labor, so as to save identification time and save The effect of manual adjustment and reduction of labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0064] As an embodiment, the dispensing module includes a three-axis adjustment module, a dispensing head and a fixture plate;

[0065] The three-axis adjustment module is used to adjust the position of the dispensing head so that the dispensing head reaches the position to be dispensed;

[0066] The dispensing head is used to dispense, dispense, inject or dispense glue based on the dispensing control instructions;

[0067] The fixture plate is used to fix the PCB board to be dispensed based on the fixation control command.

[0068] The glue dispensing module in this application can also use a piezoelectric injection valve;

[0069] As an embodiment, the three-axis adjustment module includes a servo motor and a reducer;

[0070] Servo motor is used to adjust the position of the dispensing head;

[0071] The reducer is used to decelerate the three-axis transmission module in the process of adjusting the dispensing head.

[0072] The input power of this application adopts AC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com