Continuous printing laser sintering 3D printer

A 3D printer and laser sintering technology, which is applied in the field of 3D printing, can solve problems such as poor sealing and poor stability of the workbench, and achieve the effects of improving quality, stable and reliable lifting, and improving the quality of powder coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make those skilled in the art better understand the technical solutions of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings.

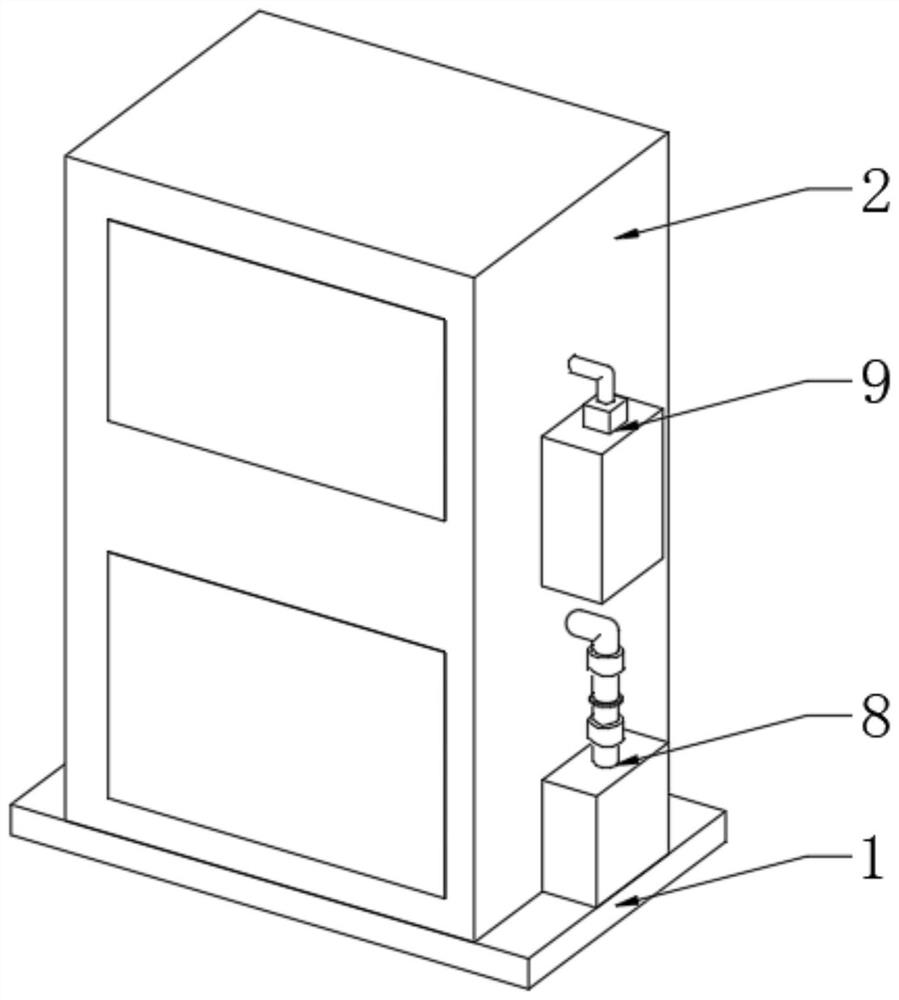

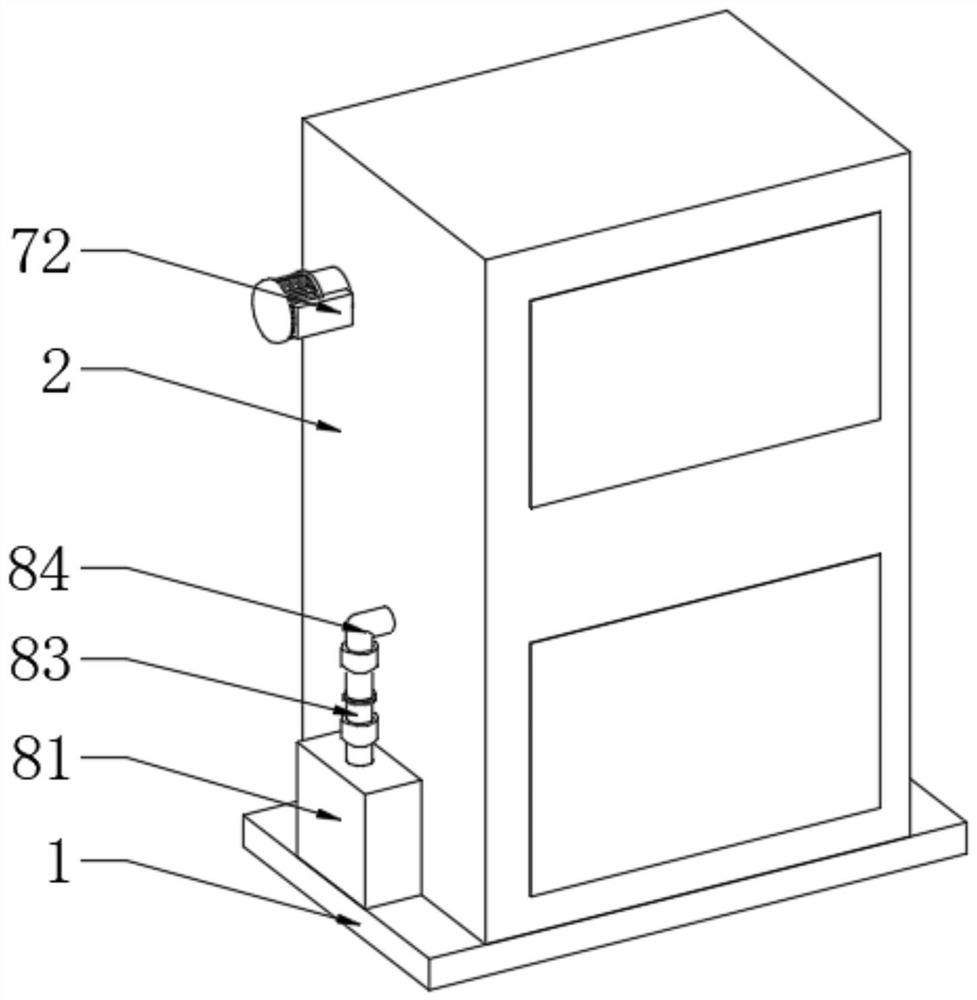

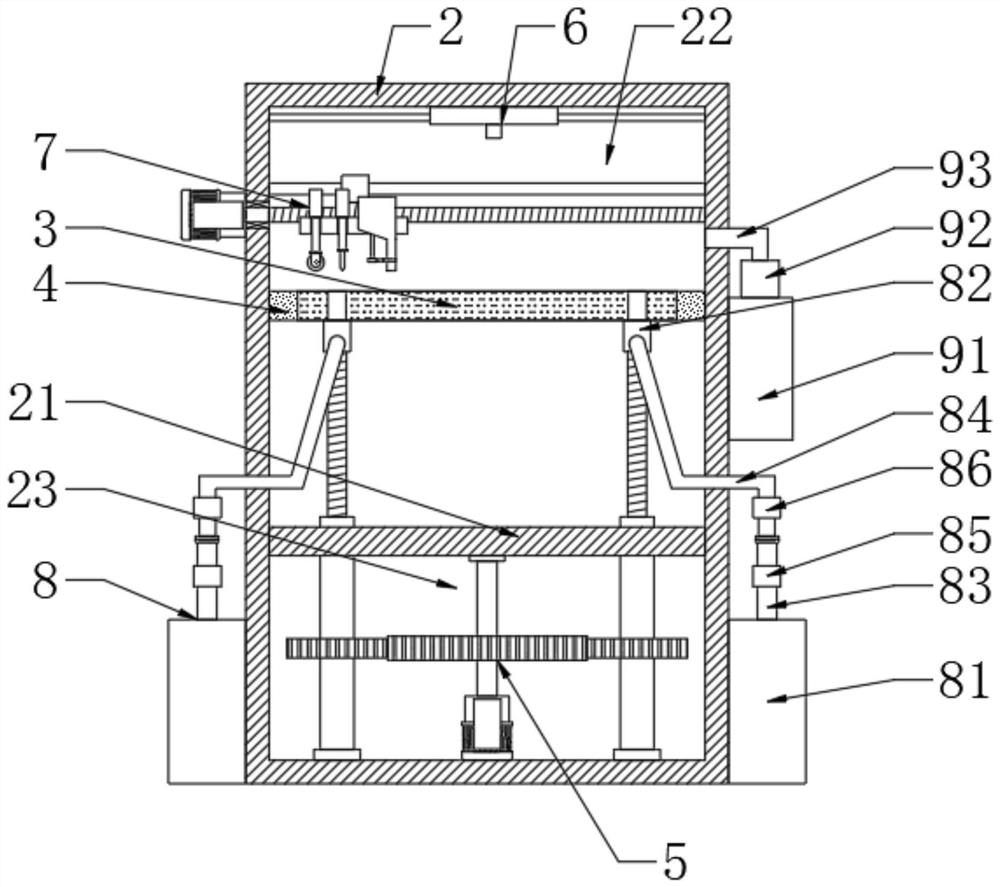

[0044] The present invention provides such as Figure 1-7 The shown continuous printing laser sintering 3D printer includes a base 1 and a casing 2, the casing 2 is mounted on the base 1, a partition 21 is fixed inside the casing 2, and a partition 21 is arranged above the partition 21. Working cavity 22, a mounting cavity 23 is provided below the partition plate 21, a working table 3 is slidably installed inside the working cavity 22, and a sealing sliding component 4 is fixedly sleeved on the periphery of the working cavity 22. The bottom of the table 3 is provided with a lifting mechanism 5, the top of the working chamber 22 is provided with a laser sintering component 6, and the interior of the working chamber 22 is provided with a powder feeding an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap