Manufacturing method of high-strength gear for forklift axle reduction gearbox

A high-strength gear and manufacturing method technology, applied in the field of gears, can solve the problems of difficult to guarantee the quality of finished products, low surface structural strength, complex cavity structure, etc., to ensure stability, reduce pouring strength and difficulty, and high pouring efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

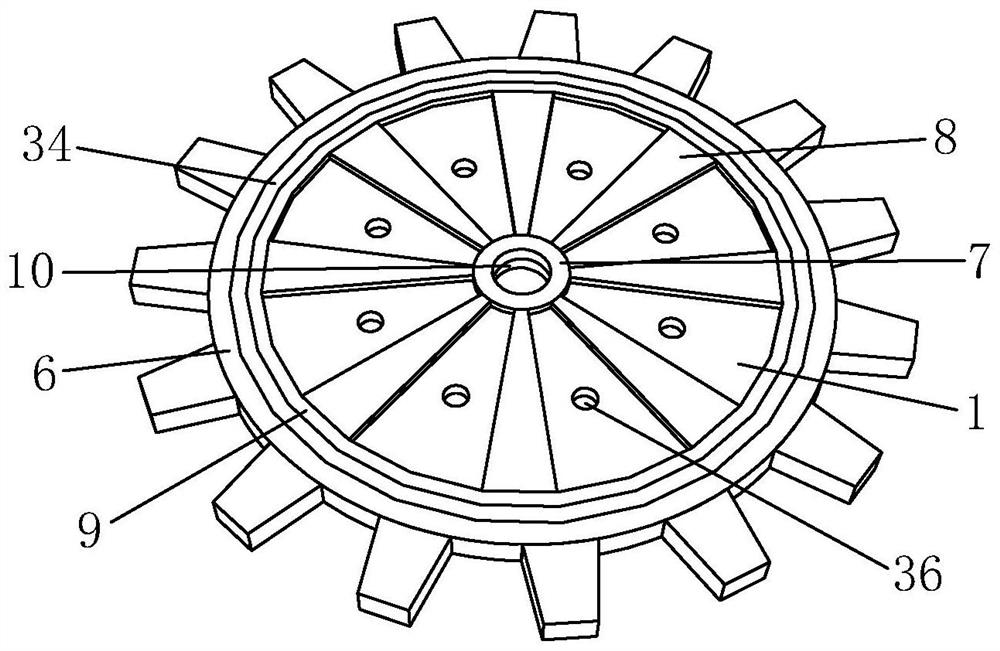

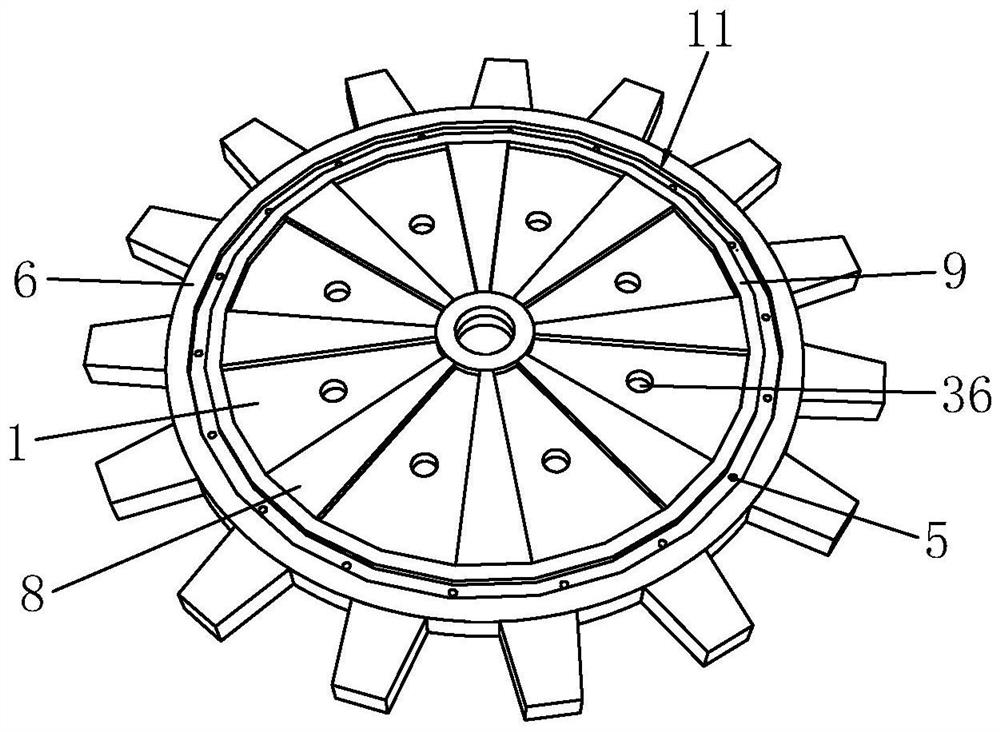

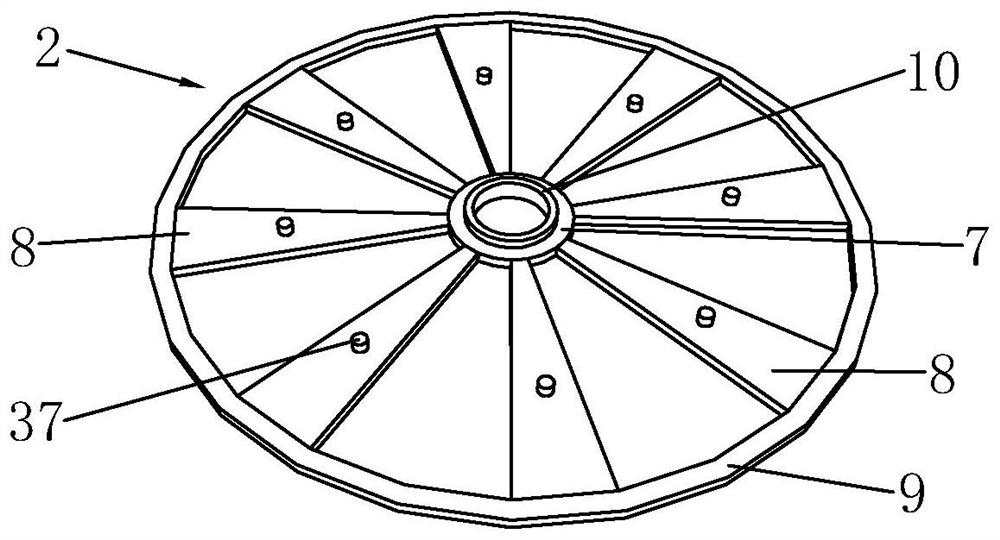

[0039] like Figure 1 to Figure 4 shown, is the high-strength gear in the present invention, such as Figure 5 to Figure 9 shown, is the pouring device used in the manufacturing method of the present invention.

[0040] A method for manufacturing a high-strength gear for a forklift axle reduction box, comprising the following steps:

[0041] (a) Preparation of crude product: gear body 1 and reinforcing rib body 2 are obtained by casting. The casting has compact structure, high mechanical properties, high dimensional accuracy and good quality.

[0042]The gear body 1 is sequentially distributed with a center hole 3, a positioning through hole 4, a casting through hole 5 and a raised portion 6 from the inside to the outside. The reinforcing rib body 2 includes an inner ring 7, a fixing rib 8 and an outer ring 9, and the fixing ribs 8 are evenly distributed. Between the inner ring 7 and the outer ring 9, the inner ring 7 is provided with a convex ring 10 corresponding to the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com