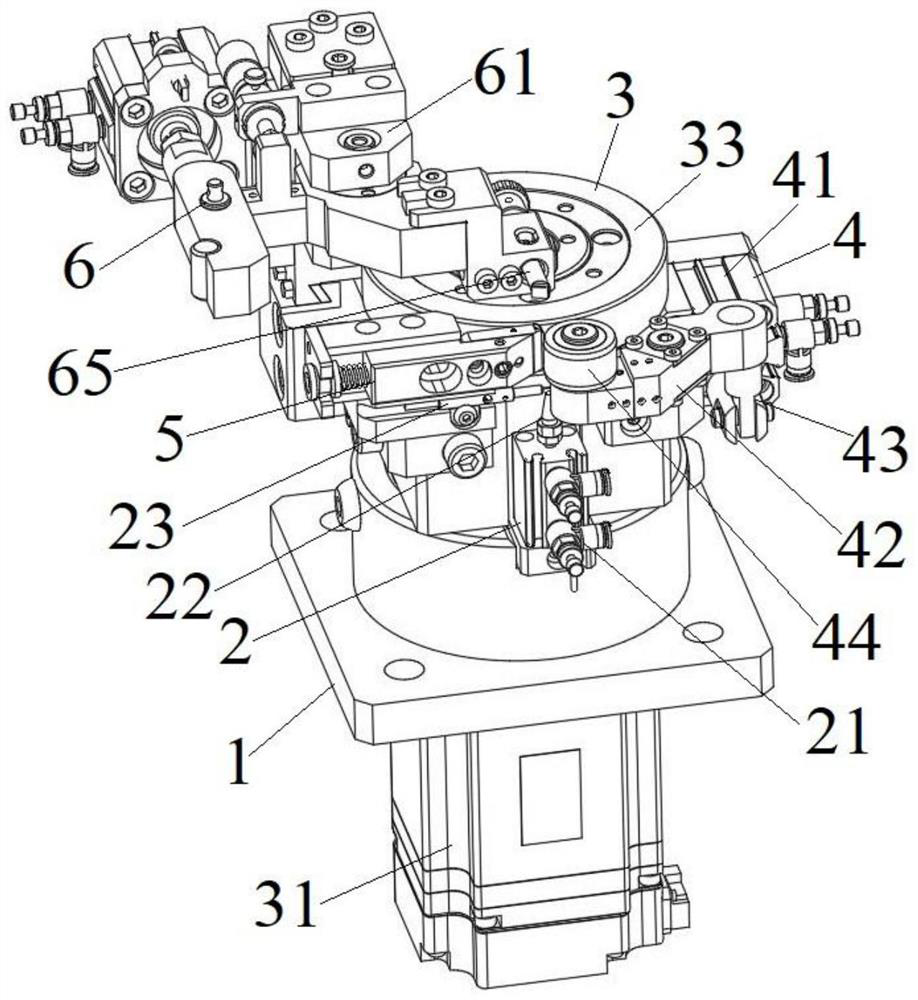

Bar clamping guide wheel mechanism for refiner

A technology of guide wheel mechanism and fine grinding machine, which is applied in the direction of grinding machine tool parts, grinding drive device, grinding workpiece support, etc., and can solve the problem of inability to meet the requirements of high-precision micro-drilling and the concentricity of bar and drill pin Low-level problems, to ensure stability, meet processing needs, and improve concentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

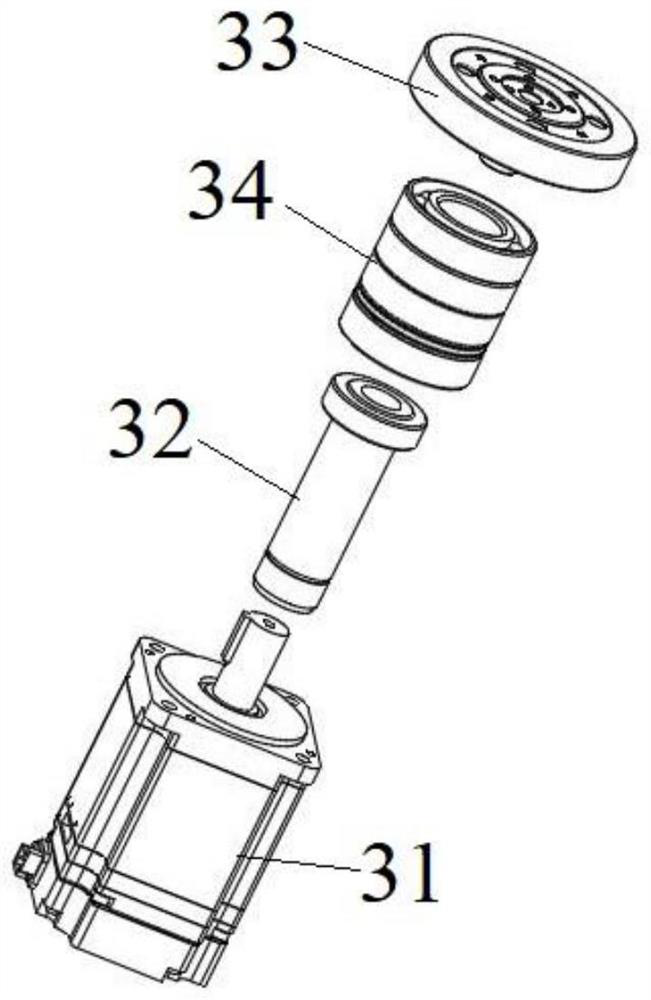

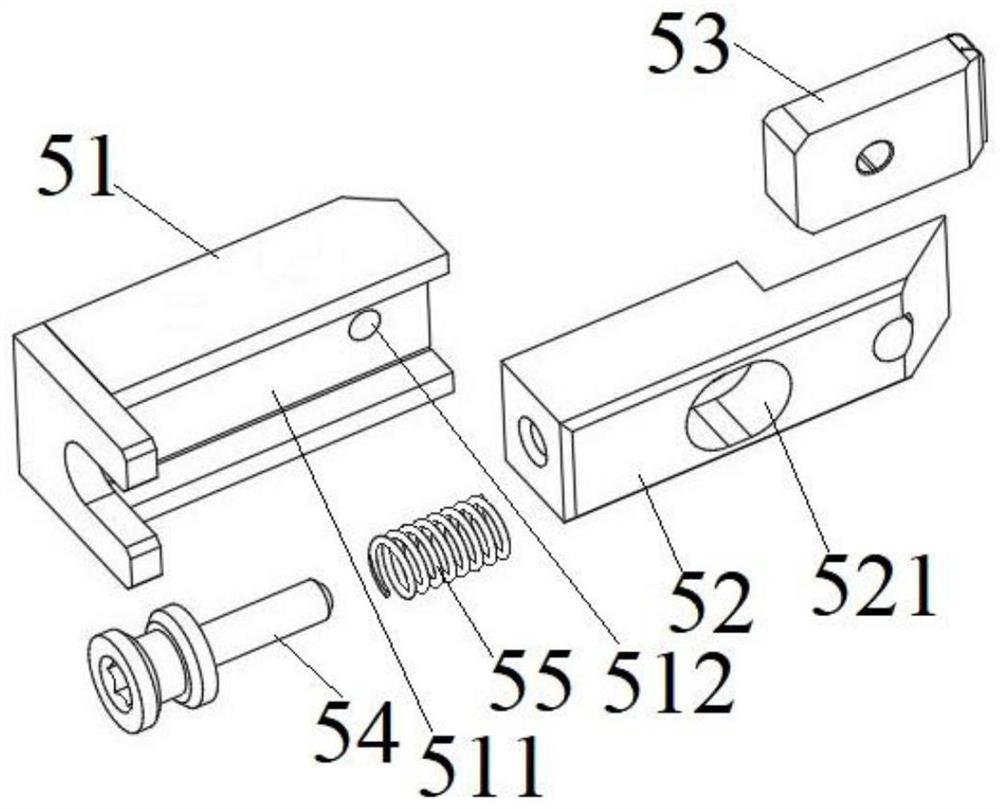

Method used

Image

Examples

Embodiment Construction

[0022] Unless otherwise defined, all technical and scientific terms used herein have the same meaning as commonly understood by one of ordinary skill in the art of this application; terms used herein in the specification of the application are for the purpose of describing particular embodiments only , is not intended to limit the application; the terms "comprising" and "having" and any variations thereof in the description and claims of this application and the above description of the drawings are intended to cover non-exclusive inclusion. The terms "first", "second" and the like in the description and claims of the present application or the above drawings are used to distinguish different objects, rather than to describe a specific order.

[0023] Reference herein to an "embodiment" means that a particular feature, structure, or characteristic described in connection with the embodiment can be included in at least one embodiment of the present application. The appearances ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com