Open-source six-degree-of-freedom robot platform based on bus control

A bus control, degree of freedom technology, applied in the field of robots, can solve the problem that the driver robot body is not integrated together

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

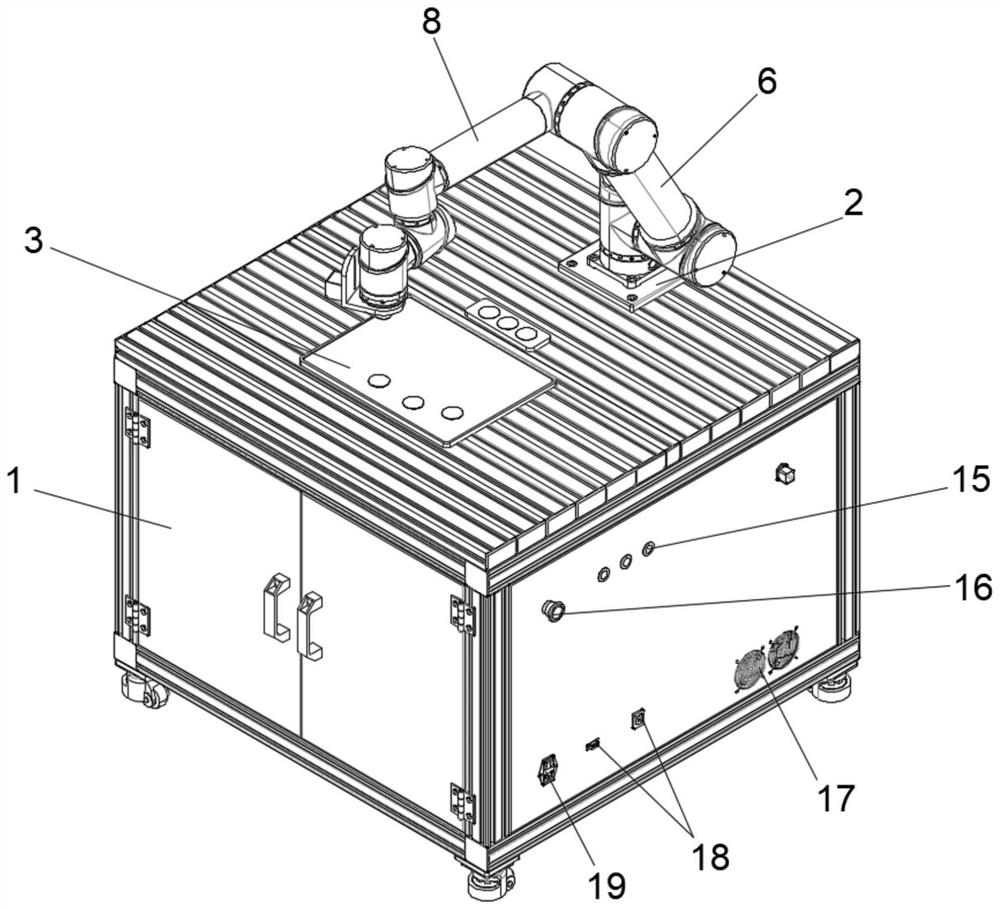

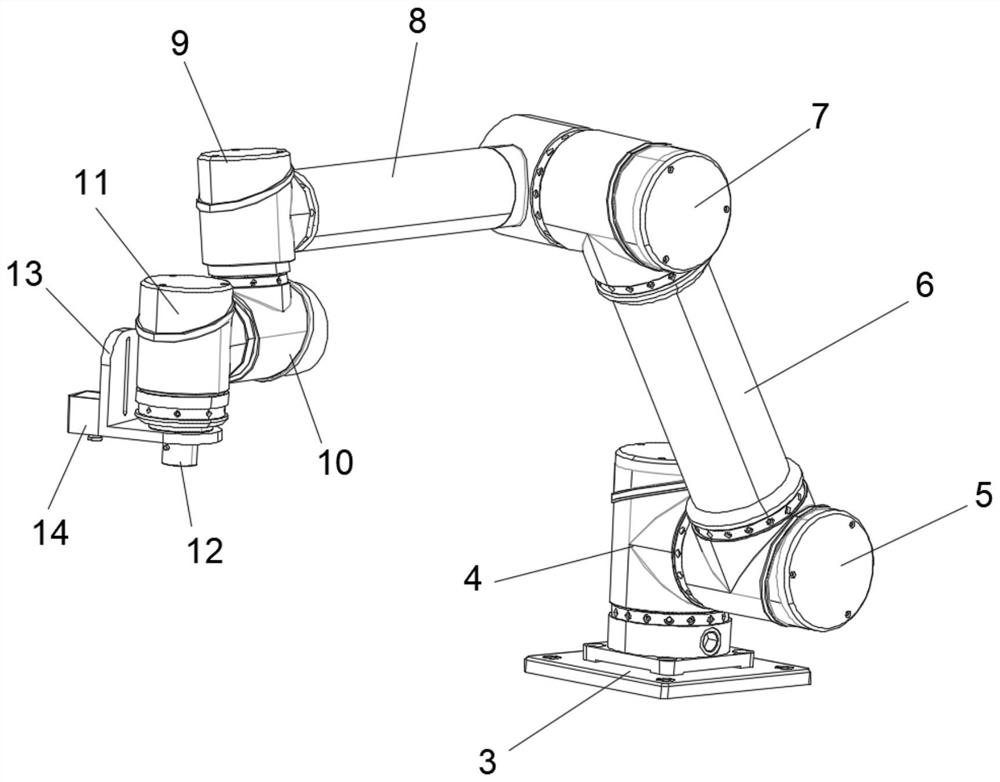

[0017] Example one, as Figure 1-2 As shown in the figure, an open source six-degree-of-freedom robot platform based on bus control includes a cabinet 1, a base 2 and a tray 3 are fixedly installed on the upper surface of the cabinet 1, and a first motor drive mechanism 4 is fixedly installed above the base 2, The output end of the first motor drive mechanism 4 is drivingly connected with the second motor drive mechanism 5, the output end of the second motor drive mechanism 5 is connected to one end of the second rotating shaft 6, and the other end of the rotating shaft 6 is fixedly installed with a third motor drive mechanism. Mechanism 7, the output end of the third motor drive mechanism 7 is connected to one end of the third rotating shaft 8, the other end of the third rotating shaft 8 is fixedly installed with a fourth motor drive mechanism 9, and the output end of the fourth motor drive mechanism 9 is connected to the third rotating shaft 8. The five motor drive mechanism...

Embodiment 2

[0021] Embodiment 2, as a further preferred solution of Embodiment 1, a power supply and a controller are installed in the cabinet 1, and a power control button 15, an emergency stop button 16, a fan 17, a communication network port socket 18 and a power supply are respectively installed on the side of the cabinet 1. Socket 19. The power control button 15 and the emergency stop button 16 are both connected to the power supply through the controller. Through the emergency stop button 16, when an emergency occurs during the operation of the robot, you can press 11 to cut off the power of the robot platform for protection.

Embodiment 3

[0022] Embodiment 3, as a further preferred solution of Embodiment 1, the output end of the sixth motor drive mechanism 11 is fixedly mounted with a vision camera mount 13 , and the vision camera mount 13 is fixedly mounted with a vision camera 14 . And the signal output end of the vision camera 14 is connected with the RTI real-time simulation controller through the signal acquisition device, and the real-time position of the grasping tool 12 can be collected in real time through the vision camera 14 to facilitate real-time control of the robot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com