Intelligent garbage can with automatic throwing function

An automatic dispensing and intelligent technology, applied in the direction of garbage cans, garbage collection, garbage cleaning, etc., can solve the problems of being unable to control the amount of garbage put in each time, incomplete separation, and affecting treatment, so as to avoid arbitrary discharge and use Safe and convenient, scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

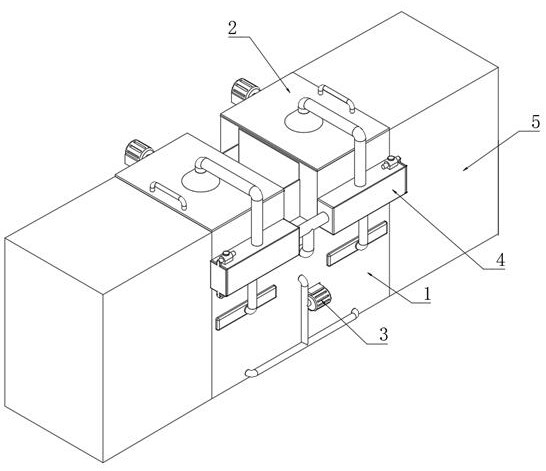

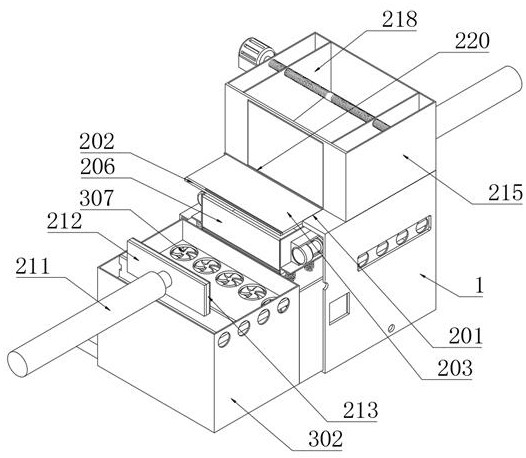

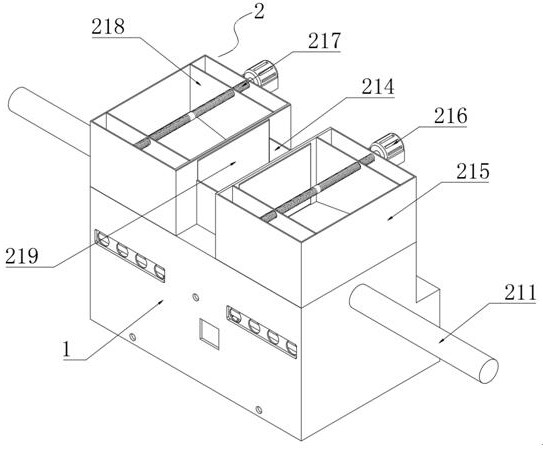

[0033] Example: as Figure 1-8As shown, the present invention provides a technical solution, an intelligent automatic throwing intelligent waste bin, comprising a fixed support box 1, a throwing screening assembly 2 is installed on one side of the fixed supporting box 1, and the throwing screening assembly 2 includes a feeding port 201 , moving electric slide rail 202, sealing limit plate 203, load-bearing support plate 204, support spring 205, screening fixing box 206, vibration motor 207, torsion spring 208, blocking fixing plate 209, screening separation net 210, discharging electric push rod 211 , installation support plate 212, screening electromagnet 213, limit protection plate 214, placement collection box 215, transmission motor 216, bidirectional screw 217, push material clamping plate 218, discharge protection plate 219, fixed electromagnet 220 and seal cover plate 221;

[0034] The bidirectional screw rod 217 is driven by the transmission motor 216 to rotate, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com