Method for regulating and controlling particle size of hydrolyzed seed crystal

A technology of crystal seed and particle size, applied in the field of titanium dioxide, can solve the problems of small particle size variation range, no production method for the particle size of hydrolyzed seeds, etc., and achieve the effect of large particle size range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

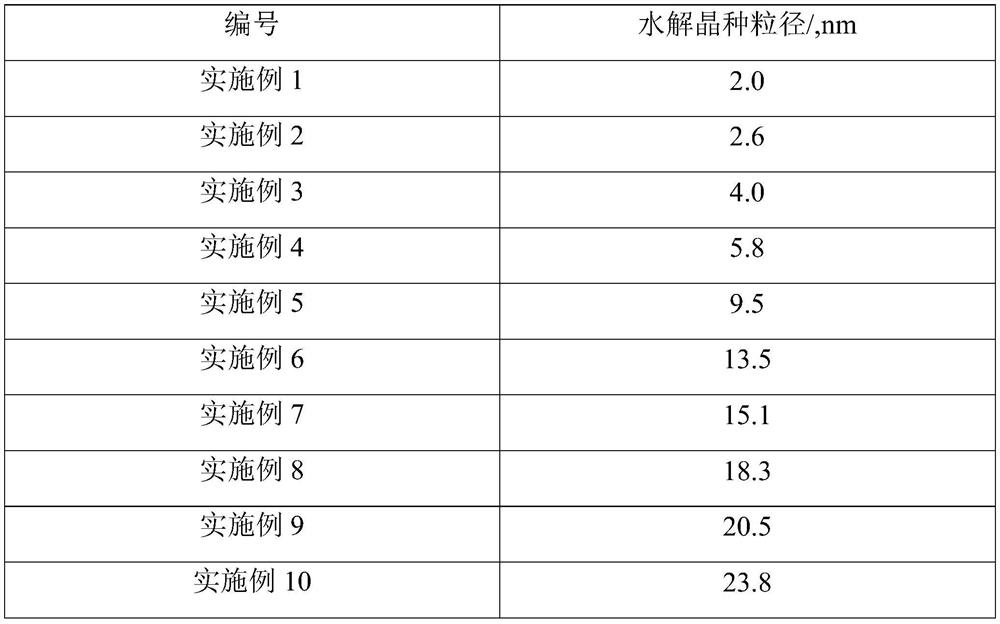

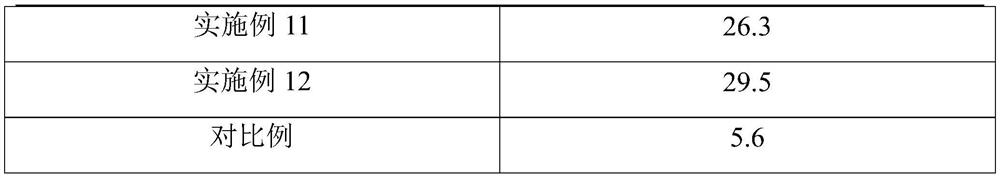

Examples

Embodiment 1

[0033] Take the titanium solution concentrated to 160g / L, divide it into two parts, preheat to 80°C and 70°C respectively, add 300ml of sodium hydroxide solution with a concentration of 120g / L to the flask, preheat to 100°C for 10 minutes Quickly add a titanium solution with a temperature of 80 °C, stir rapidly until the pH of the system = 2.5, and ripen for 20 minutes, continue to add a titanium solution at a temperature of 70 °C, and stir until the pH of the system = 2.5, at 70 °C, ripen for 40 minutes; Hydrolyzed seeds.

Embodiment 2

[0035] Take the titanium solution concentrated to 170g / L, divide it into two parts, preheat to 90°C and 75°C respectively, then add 300ml of sodium hydroxide solution with a concentration of 110g / L to the flask, preheat to 95°C for 8min Quickly add a titanium solution with a temperature of 90°C, stir rapidly until the pH of the system = 3.0, and ripen for 30 minutes, continue to add a titanium solution at a temperature of 75°C, and stir until the pH of the system = 2.0, and at 80 °C, ripen for 30 minutes; Hydrolyzed seeds.

Embodiment 3

[0037] Take the titanium solution concentrated to 180g / L, divide it into two parts, preheat to 95°C and 60°C respectively, then add 300ml of sodium hydroxide solution with a concentration of 100g / L to the flask, preheat to 90°C for 6 min Quickly add a titanium solution with a temperature of 95°C, stir rapidly until the pH of the system = 3.5, and ripen for 10 minutes, continue to add a titanium solution at a temperature of 60°C, and stir until the pH of the system = 1.7, and at 85 °C, ripen for 20 minutes; Hydrolyzed seeds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com