Platinum channel non-heating area thermal state maintenance method

A platinum channel and heating zone technology, applied in feeding troughs, manufacturing tools, glass furnace equipment, etc., can solve the problems of long time, high cost, low efficiency, etc., and achieve the effect of saving material, improving efficiency and saving time

Active Publication Date: 2022-08-05

湖南旗滨医药材料科技有限公司

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This method is time consuming, inefficient and expensive

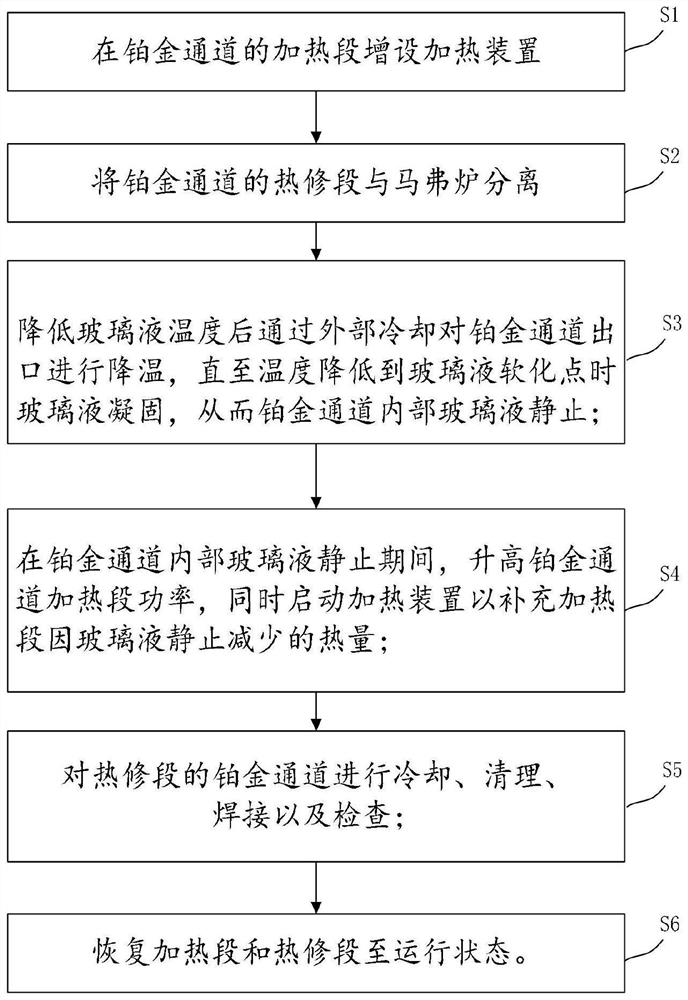

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

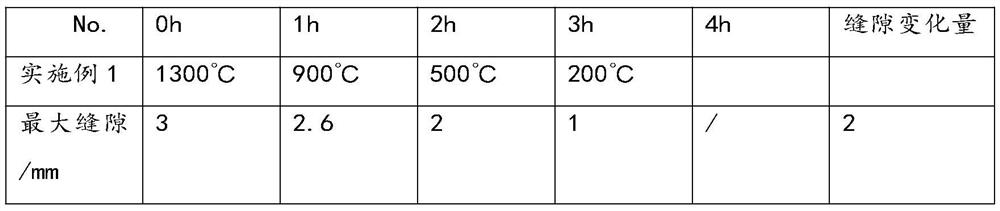

Embodiment 1

[0044] Example 1 (initial temperature is 1300°C, temperature interval is 400°C / h)

[0045]

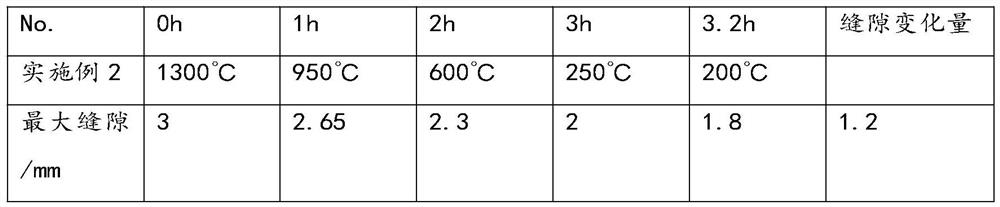

Embodiment 2

[0046] Example 2 (initial temperature is 1300°C, temperature interval is 350°C / h)

[0047]

Embodiment 3

[0048] Example 3 (initial temperature is 1300°C, temperature interval is 300°C / h)

[0049]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the technical field of glass production, in particular to a hot-state maintenance method for a platinum channel, and more particularly relates to a hot-state maintenance method for a non-heating section of a platinum channel body, so as to change the current situation that the platinum channel body cannot be maintained in a hot state in the prior art. Comprising the following steps: additionally arranging a heating device on a heating section of a platinum channel; separating the hot repair section of the platinum channel from the muffle furnace; after the temperature of the glass liquid is reduced, an outlet of the platinum channel is cooled through external cooling; increasing the power of a heating section of the platinum channel and starting a heating device at the same time when the glass liquid in the platinum channel is static; and the platinum channel of the hot repair section is cooled, cleaned, positioned, welded and checked. According to the invention, non-disassembly type maintenance is carried out in a thermal state, thermal state repair can be carried out on defects existing in design, continuous leakage of molten glass at a damaged part is avoided, bubbles and other defects introduced in the leakage process of the molten glass are avoided, and erosion of the leaked molten glass and a refractory material is avoided.

Description

technical field [0001] The invention relates to the technical field of glass production, in particular to a method for hot-state maintenance of a platinum channel. Background technique [0002] With people's continuous pursuit of living materials, the quality requirements for special glass and medical glass are also constantly improving, and such high-end glass also uses platinum channels. Platinum channels are generally composed of platinum body and peripheral refractory materials and steel structures. , and the platinum body is made of precious metal platinum and its alloys, which has many advantages such as high temperature resistance, corrosion resistance, and little pollution to the glass liquid. In use, the platinum channel is generally divided into a heating area and a non-heating area. Specifically: the heating area refers to passing the current to the platinum pipe and using the resistance of the platinum pipe to heat it, so there are more insulation materials aroun...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C03B5/225C03B7/02

CPCC03B5/225C03B7/02Y02P40/57

Inventor 安东胡义斌叶璨璟李建民陈磊

Owner 湖南旗滨医药材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com