Carbonization equipment for biomass particle production

A biomass pellet and carbonization technology, which is applied to biofuels, waste fuels, coke ovens, etc., can solve the problems of affecting the carbonization effect of biomass pellets, unable to heat the biomass pellets uniformly, and poor mixing effect of biomass pellets. Carbonization effect, improved carbonization efficiency, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

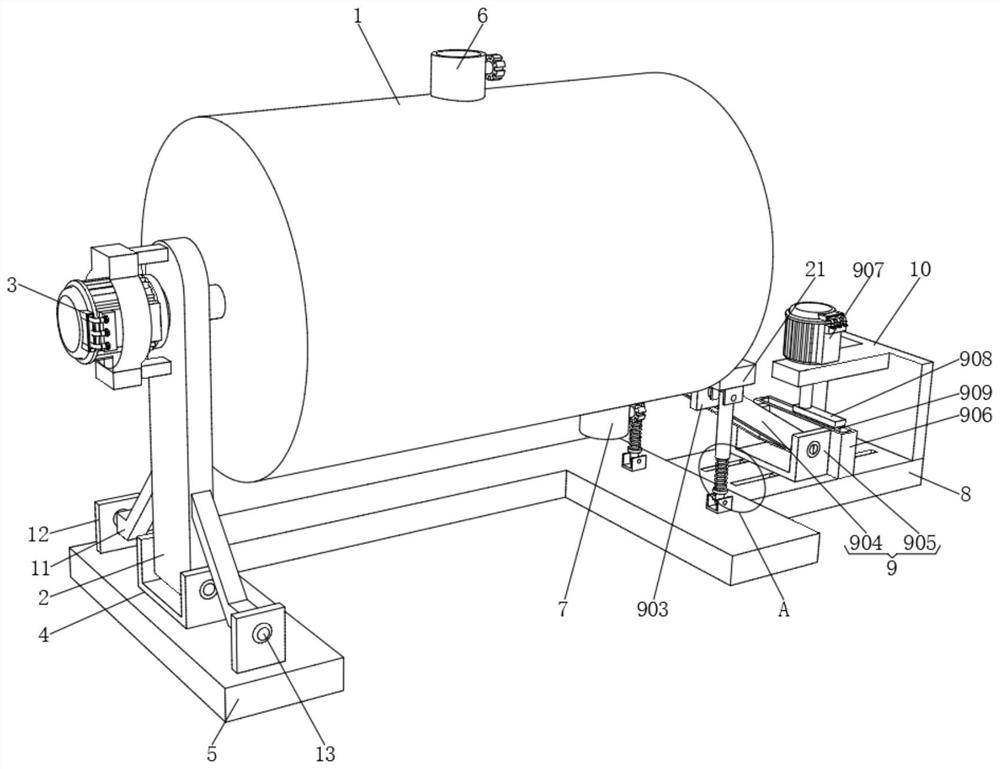

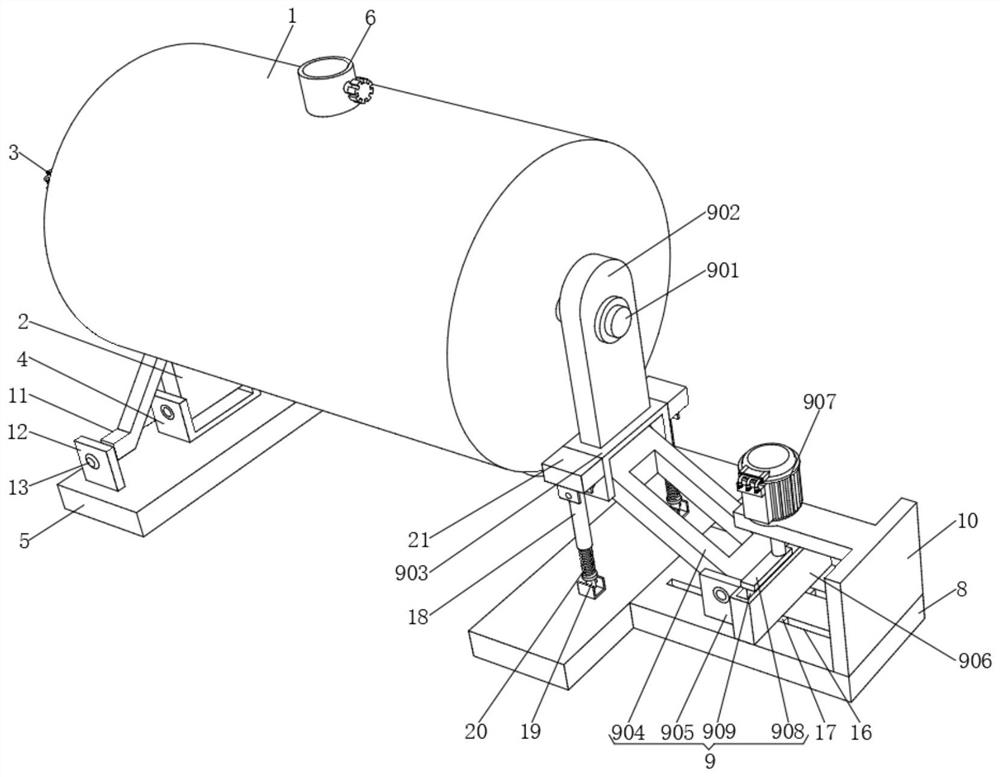

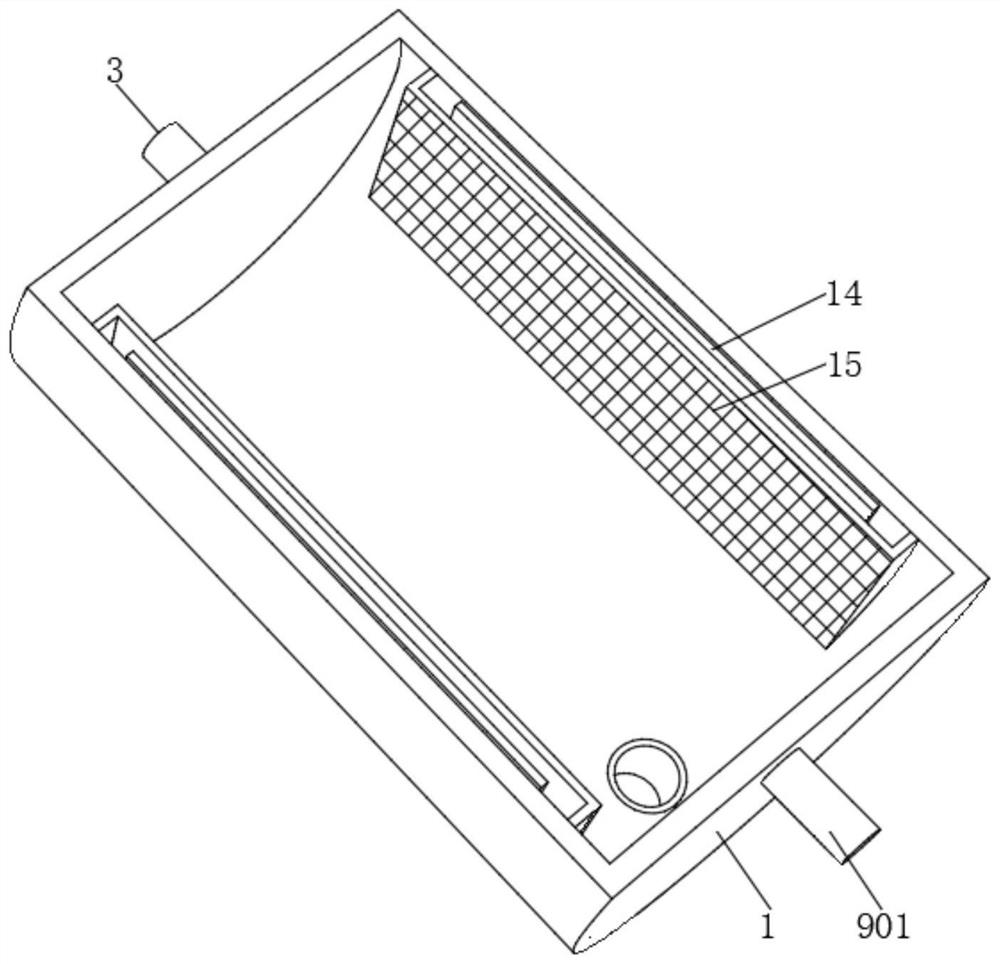

[0026] refer to Figure 1-Figure 5 , a carbonization equipment for biomass particle production, comprising a drum 1 and a support plate 2, the drum 1 is connected with a feed pipe 6, the bottom side of the drum 1 is communicated with a discharge pipe 7, the feed pipe 6 and The discharge pipe 7 is provided with a valve, which can control the opening and closing of the feed pipe 6 and the discharge pipe 7. The front and back of the inner cavity of the drum 1 are provided with heating plates 14, and the heating plates 14 can be rotated in opposite directions. The inside of the drum 1 is heated to promote the carbonization of the biomass particles. A first motor 3 is fixedly connected to one side of the support plate 2. The output end of the first motor 3 penetrates the support plate 2 and is fixedly connected to one side of the rotating drum 1. The support plate The bottom of 2 is rotatably connected with a fixed seat 4 through a movable shaft, the bottom of the fixed seat 4 is f...

Embodiment 2

[0028] refer to Figure 1-Figure 5, the present invention provides a new technical solution: a carbonization device for biomass particle production, comprising a rotating drum 1 and a support plate 2, the rotating drum 1 is connected with a feeding pipe 6, and one side of the bottom of the rotating drum 1 is connected with a The discharge pipe 7, the feed pipe 6 and the discharge pipe 7 are all provided with valves, which can control the opening and closing of the feed pipe 6 and the discharge pipe 7. The front and back of the inner cavity of the rotating drum 1 are provided with The heating plate 14, the heating plate 14 can heat the inside of the drum 1 to promote the carbonization of the biomass particles. The front and back of the inner cavity of the drum 1 are provided with a protective frame 15. The heating plate 14 is located in the protective frame 15, and the protective frame 15 can be The heating plate 14 is protected to prevent the biomass particles from impacting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com