Similar modeling method for spray evaporation two-phase flow process

A technology of spray evaporation and phase flow, which is applied in the field of multiphase flow organization, can solve the problems of high cost, safety risk, difficulty in reproduction, and restriction of gas-liquid two-phase flow process, so as to reduce test cost and test safety risk, Applicable to a wide range of temperature parameters, easy to operate and implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

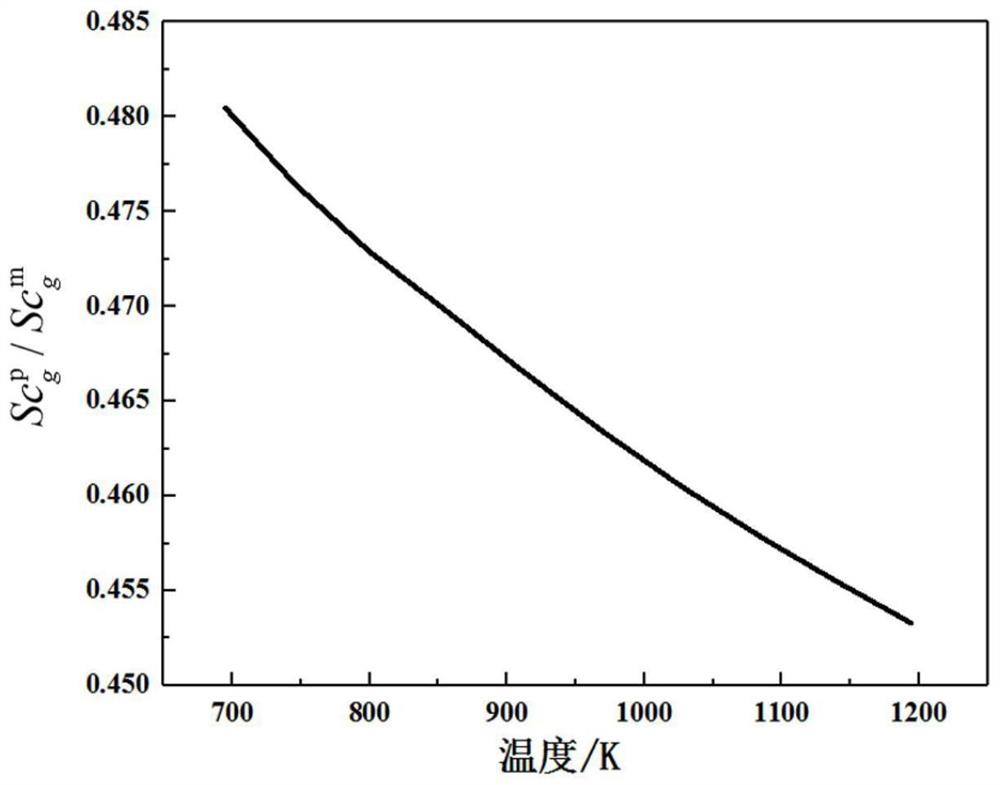

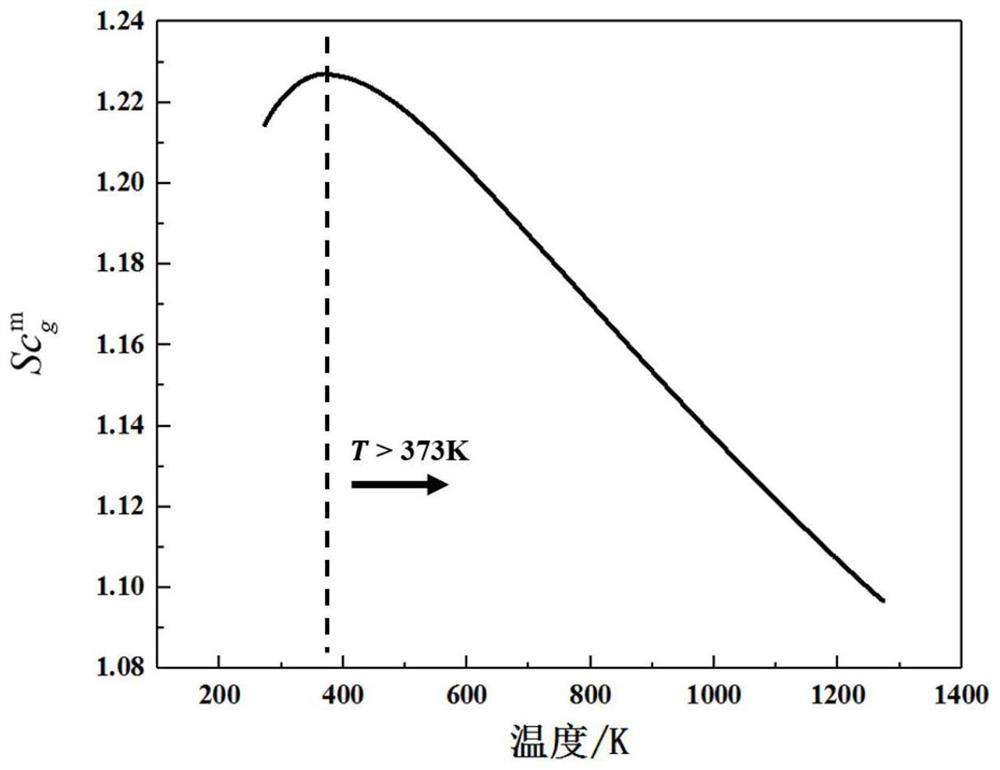

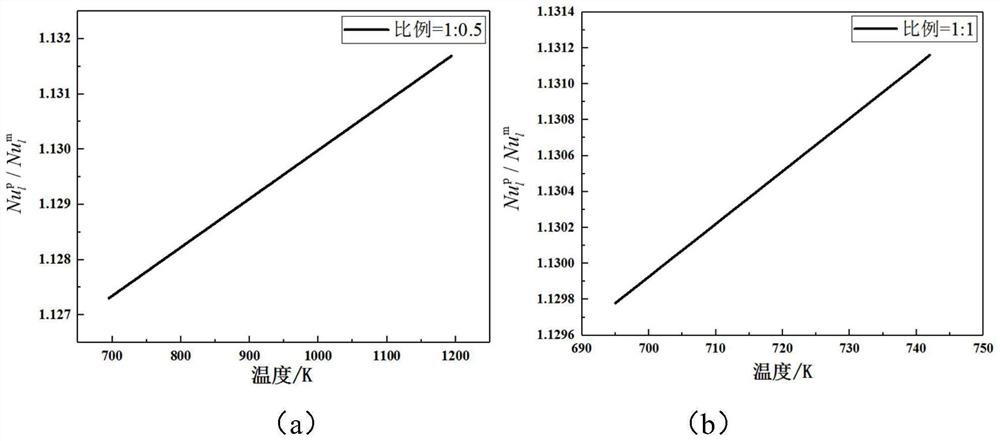

[0105] see Figure 4 , Figure 4 This is a schematic diagram of the structure of a spray-evaporation mixing chamber in this embodiment; the spray-evaporation mixing chamber is a rectangular pipe structure with a cross-sectional dimension of D×D and a length of L. The size of the prototype mixing chamber is 0.1m×0.1m×0.8m, the size of the model mixing chamber with a size ratio of 1:0.5 is 0.05m×0.05m×0.4m, and the size of the model mixing chamber with a size ratio of 1:1 is 0.1m×0.1m×0.8m. The spray injection position is 0.25L away from the inlet of the mixing chamber; the cross-flow gas is air, the prototype spray working fluid is water, and the model spray working fluid is acetone.

[0106] According to the similar modeling method of the present invention, two groups of single droplet motion trajectories are calculated by comparing two model sizes with a ratio of 1:1 and 1:0.5 respectively.

[0107] Table 1 Working parameters under the condition that the ratio of prototype...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com