Membrane-electrode assembly, method of manufacturing the same, and fuel cell comprising the membrane-electrode assembly

An electrode assembly and electrode technology, which is applied in fuel cells, electrical components, battery electrodes, etc., can solve the problems of durability degradation, loss of active area of membrane-electrode assembly, etc., and achieve the effect of increasing active area and improving fluid control ability

Pending Publication Date: 2022-08-05

KOLON IND INC

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, exposure of the electrolyte membrane between the sub-electrodes causes loss of active area and deterioration of durability of the membrane-electrode assembly

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0109] according to Figures 5a to 5h Process shown in Manufactured using decal transfer method figure 1 Membrane-electrode assembly (double-sided patterned cathode + conventional anode) shown in . The cathode was formed using a Pt / C catalyst (0.4 mg Pt / cm 2 ) and anode (0.1mg Pt / cm 2 ), and a fluorine-based polymer electrolyte membrane with a thickness of 18 μm was used.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Login to View More

Abstract

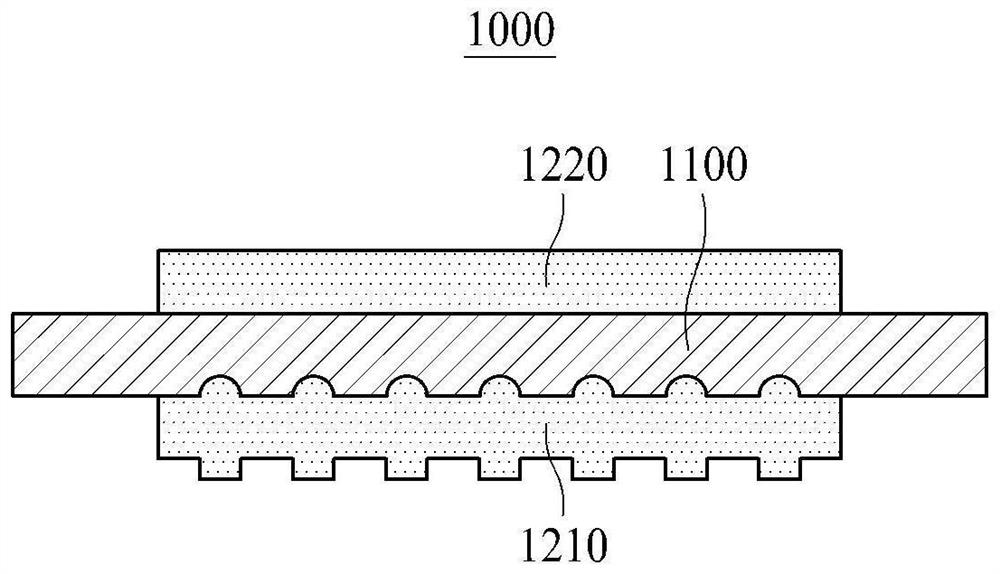

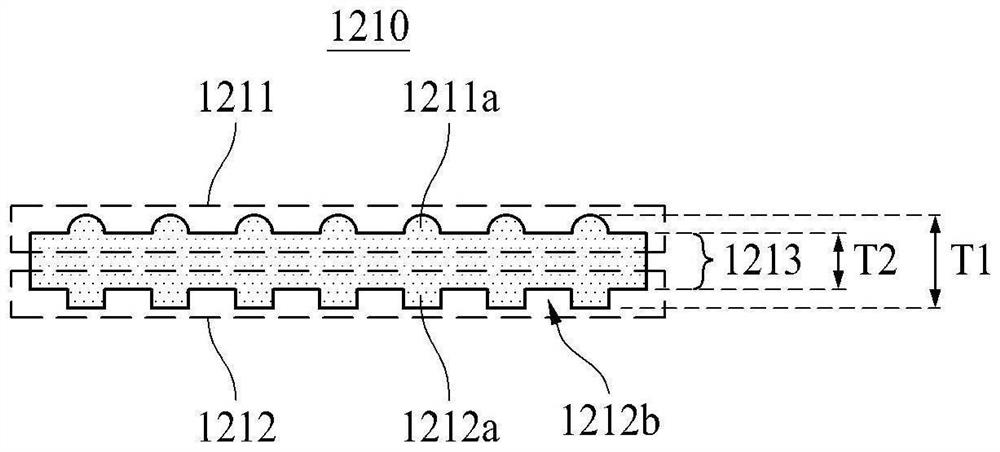

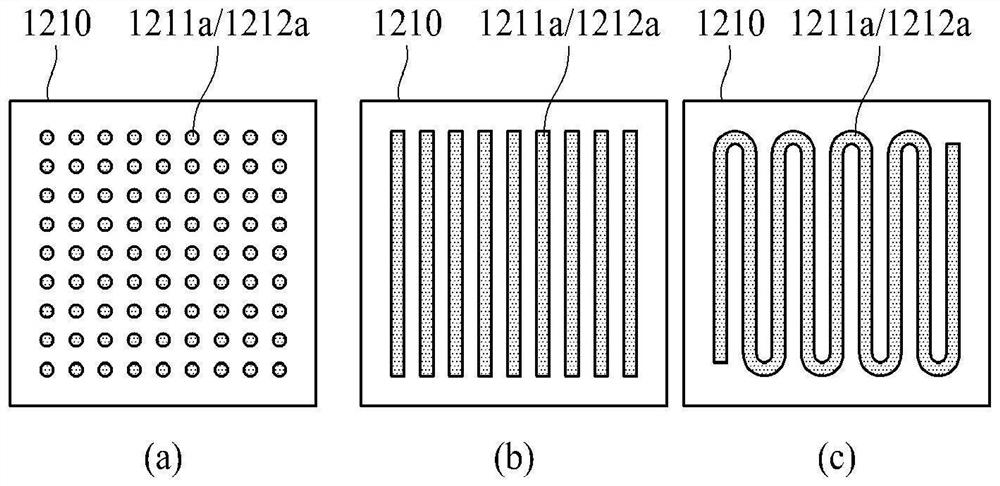

The present application discloses a membrane-electrode assembly having an increased active area, improved fluid control capability, and reduced gas transport resistance due to electrodes having a patterned structure on both sides. A method of manufacturing the membrane-electrode assembly and a fuel cell including the membrane-electrode assembly are also disclosed. The membrane-electrode assembly according to the present invention comprises: a first electrode; a second electrode; and a polymer electrolyte membrane between the first electrode and the second electrode, in which the first electrode has a first surface facing the polymer electrolyte membrane and a second surface opposite the first surface, the first surface has a first patterned structure, and the second surface has a second patterned structure.

Description

technical field [0001] The present disclosure relates to a membrane-electrode assembly, a method of making the membrane-electrode assembly, and a fuel cell including the membrane-electrode assembly, and more particularly, to a membrane-electrode assembly having an increased active area, improved Membrane-electrode assembly with improved fluid control capability and reduced gas transport resistance, method of making the membrane-electrode, and fuel cell including the membrane-electrode assembly. Background technique [0002] Polymer Electrolyte Membrane Fuel Cells (PEMFCs) are constructed to use the structure of each stack of unit cells including a membrane-electrode assembly (MEA) and a separator (also known as a bipolar plate) to generate electricity due to its high energy efficiency and environmentally friendly features , so it has attracted attention as a next-generation energy that can replace fossil fuels. [0003] A membrane-electrode assembly typically includes an an...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01M8/1065H01M4/88H01M8/1004H01M8/1018

CPCH01M8/1018H01M8/1004H01M8/1065H01M4/88Y02E60/50Y02P70/50H01M4/86H01M8/0258H01M8/026H01M4/881H01M4/8814H01M2008/1095H01M4/8878H01M4/8882H01M4/8828H01M8/1006H01M4/8892

Inventor 孔络园南暻植宋佳映金埈永李主圣

Owner KOLON IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com