Electronic and mechanical double-control battery pack fire extinguishing system

A technology for a fire extinguishing system and a battery pack, applied in the field of a battery pack fire extinguishing system, can solve the problem that the battery pack cannot extinguish fire, and achieve the effects of simplifying the structure, reducing fire accidents, and increasing the probability of fire extinguishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

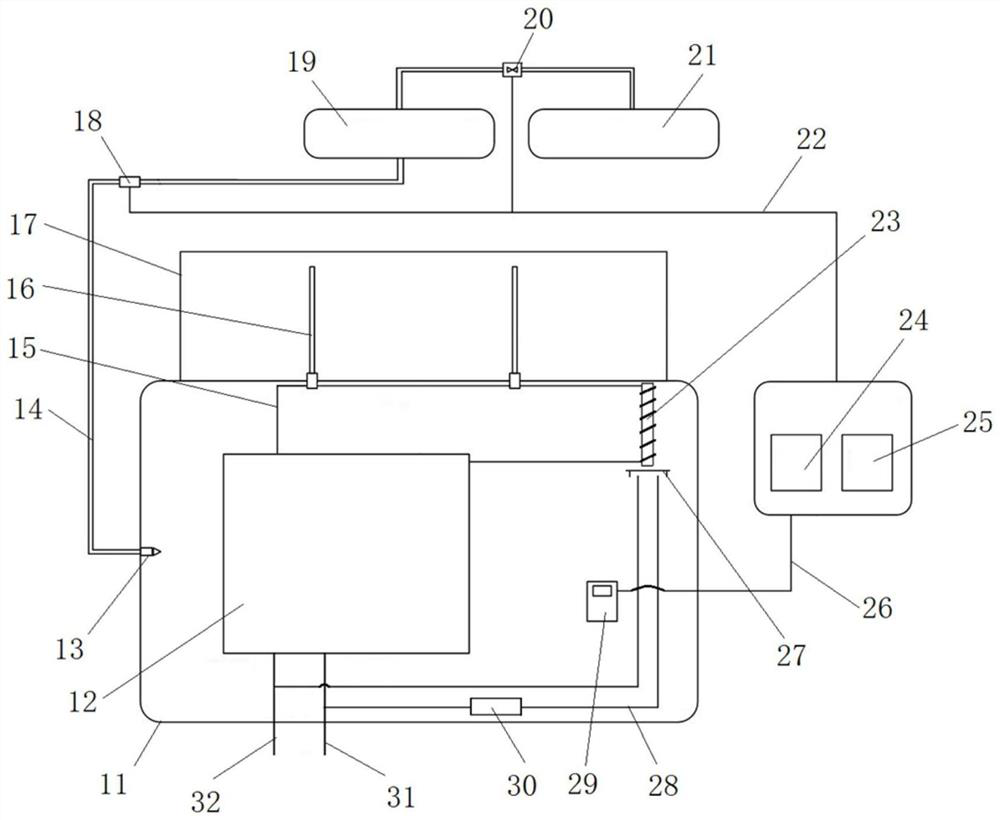

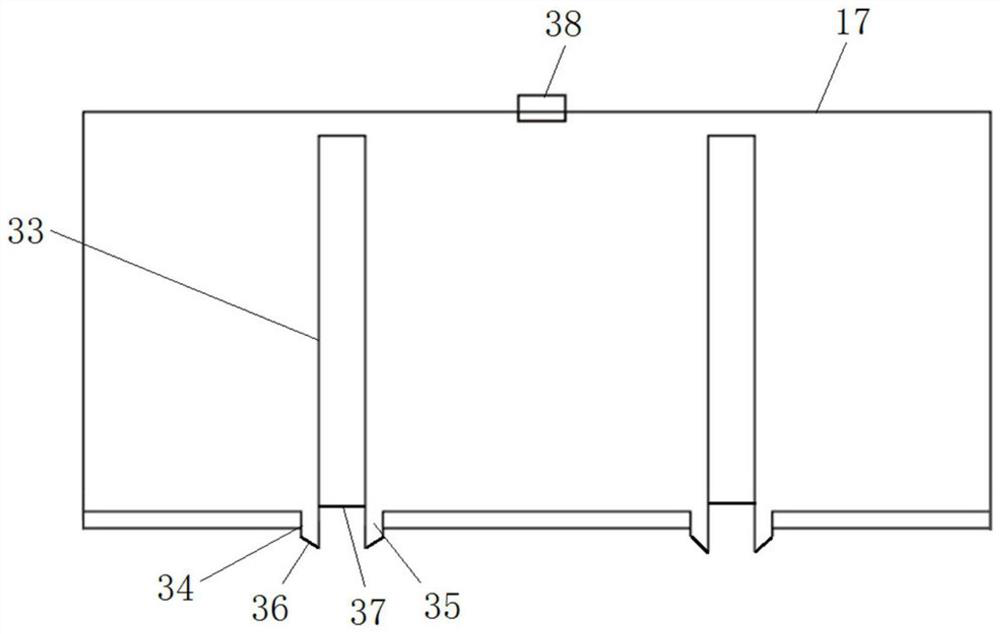

[0039] like figure 1As shown, the electronic and mechanical dual-control battery pack fire extinguishing system includes a casing 11, an electronic fire extinguishing device, a mechanical fire extinguishing device and a controller. The casing 11 is provided with a battery pack 12 and a temperature sensor 29, and the temperature sensor 29 is used for monitoring the casing. temperature inside the body 11. The battery pack 12 includes devices such as battery cells and a battery control board connected in series, and the casing 11 and the battery pack 12 together form a battery pack.

[0040] In this embodiment, the battery pack 12 is connected with the main loop positive line 31 and the main loop negative line 32, and the main loop positive line 31 and the main loop negative line 32 are respectively connected with two adjacent battery packs, so as to realize the connection between the battery packs. concatenation between.

[0041] In this embodiment, the electronic fire extingu...

Embodiment 2

[0058] The difference between this embodiment and Embodiment 1 is that, in Embodiment 1, the bypass protection circuit realizes bypass protection by melting a fusible conductor. In this embodiment, the bypass protection circuit realizes the bypass protection by controlling the electronic switch by the controller.

Embodiment 3

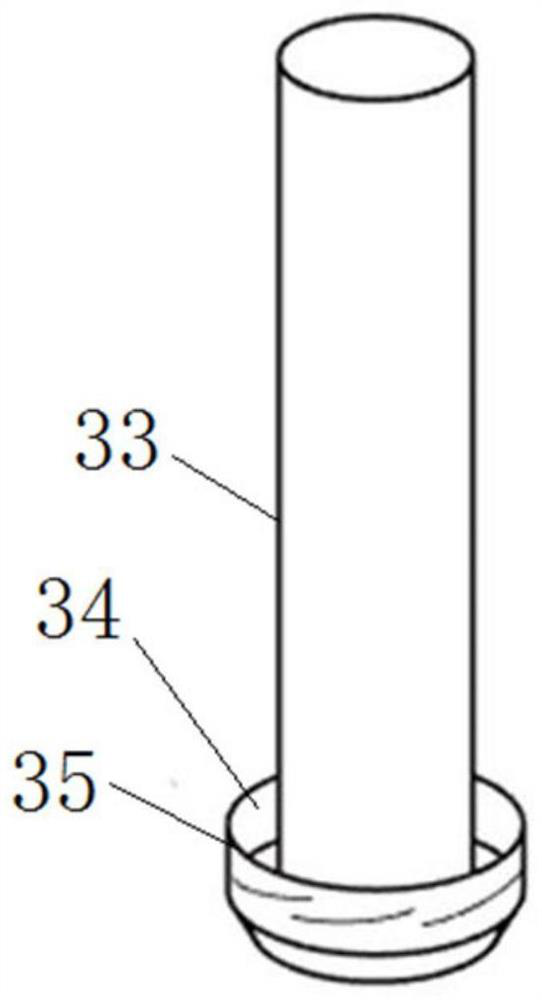

[0060] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the fusible body of the nozzle on the second nozzle is a fusible conductor on the series circuit. In this embodiment, the fusible body of the spout on the second nozzle and the fusible conductor on the series circuit are arranged independently. At this time, the fusible body of the nozzle on the second nozzle can be a fusible conductor or a fusible conductor. non-conductor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com