High-adaptability direct charging power supply for lithium battery tool

A technology of adaptability and charging source, applied in the field of direct charging source for lithium electric tools, can solve the problems of reduced battery life, easy corrosion of direct charging source, affecting the stability of direct charging source, etc., to improve heat absorption and guarantee Thermal energy volatilization, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

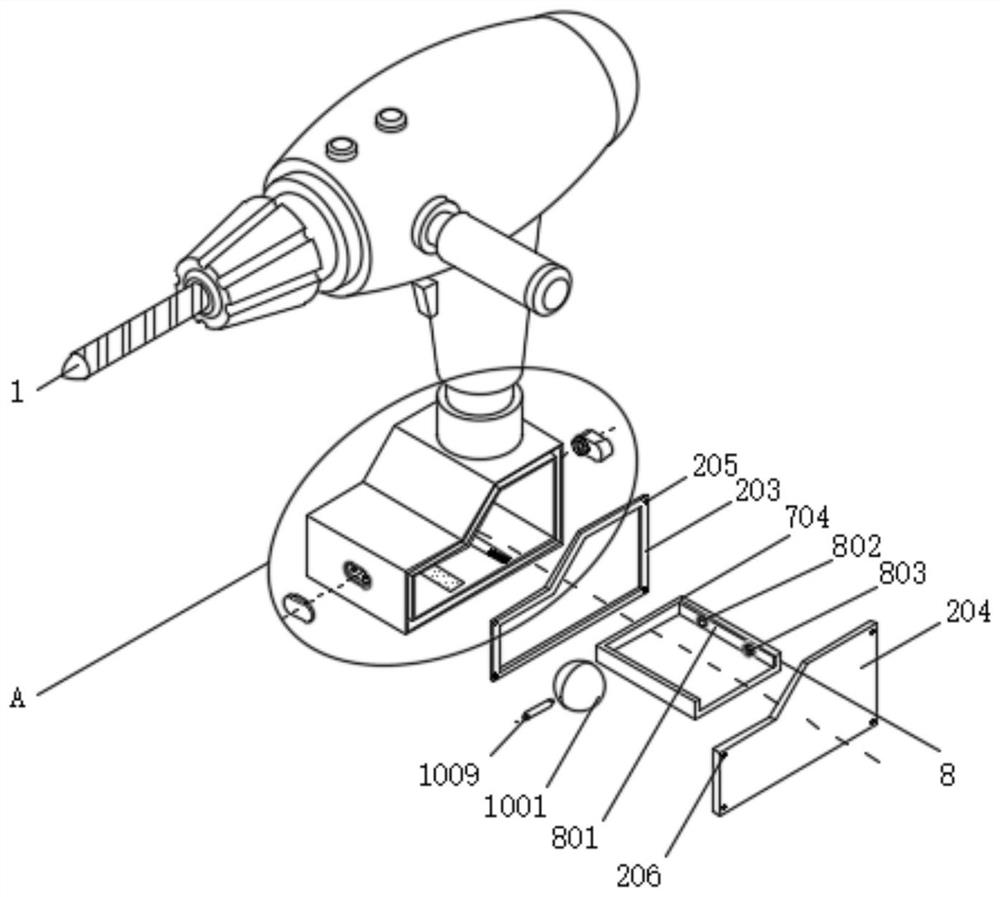

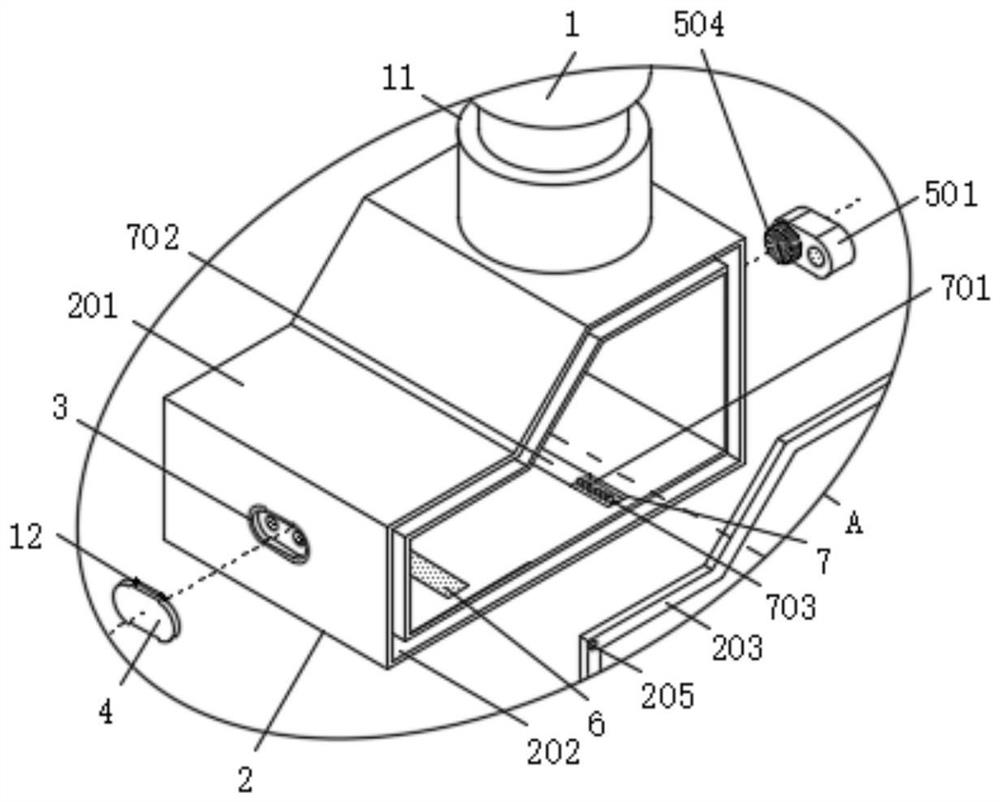

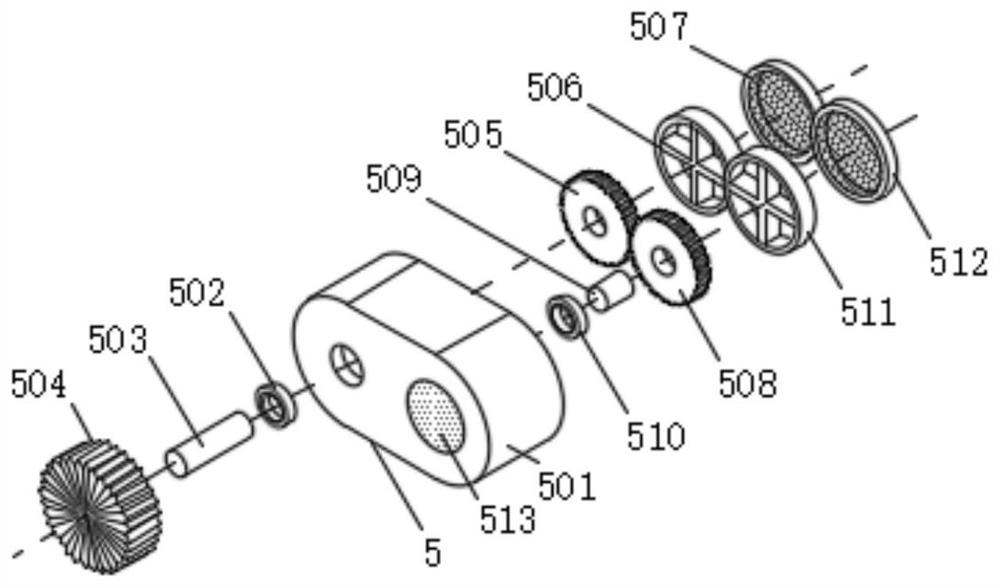

[0045] The following is attached Figure 1-8 The present invention is described in further detail.

[0046] see Figure 1-4 , the present invention provides a technical solution: a direct charging source for lithium electric tools with high adaptability, including a lithium electric tool main body 1, the bottom of the lithium electric tool main body 1 is fixedly connected to one end of an elastic connection assembly 11, and the elastic connection assembly 11 The other end is fixedly connected with the outer protective assembly 2, and the side end surface of the outer protective assembly 2 is clamped with the driving assembly 5, and the driving assembly 5 is also located inside the outer protective assembly 2, and the bottom inside the outer protective assembly 2 is provided with an ejection assembly 7 An electrical connection assembly 8 is bonded to the inner end surface of the ejection assembly 7, and an elastic sealing assembly 9 is arranged on the front end surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com