Liquid nitrogen freezing crusher suitable for biomedical degradable materials

A degradable material, liquid nitrogen freezing technology, applied in grain processing, plastic recycling, recycling technology and other directions, can solve the problems of uncontrollable powder particle size, moisture condensation, long powder transmission path, etc., to achieve precise control, Guarantee the effect of use and meet the effect of use requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

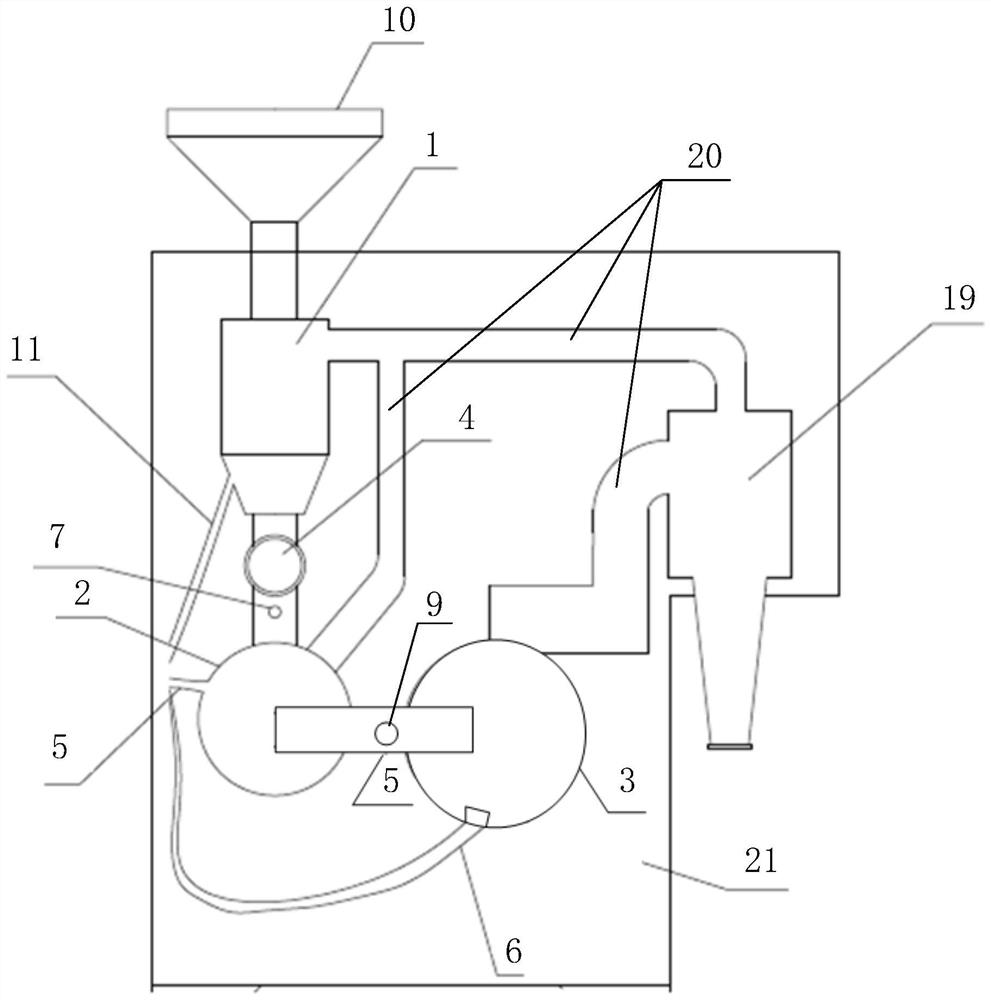

example 1

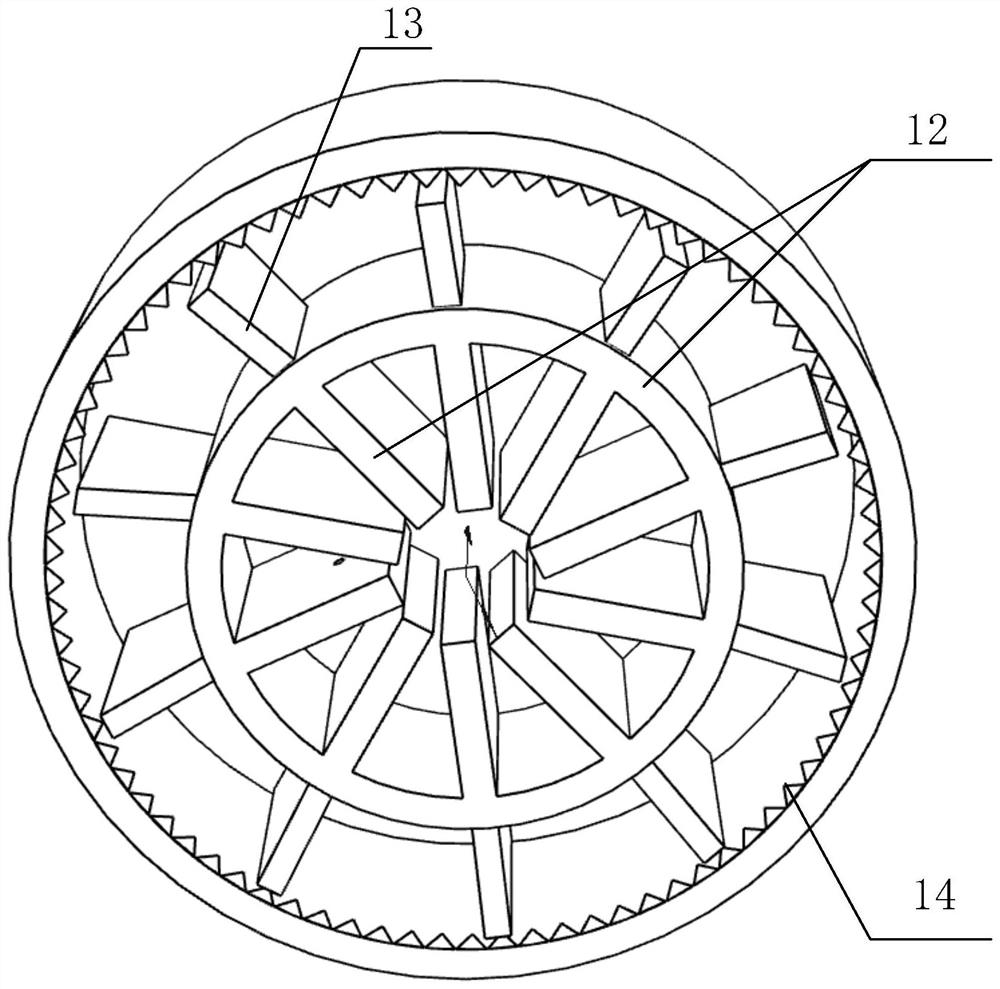

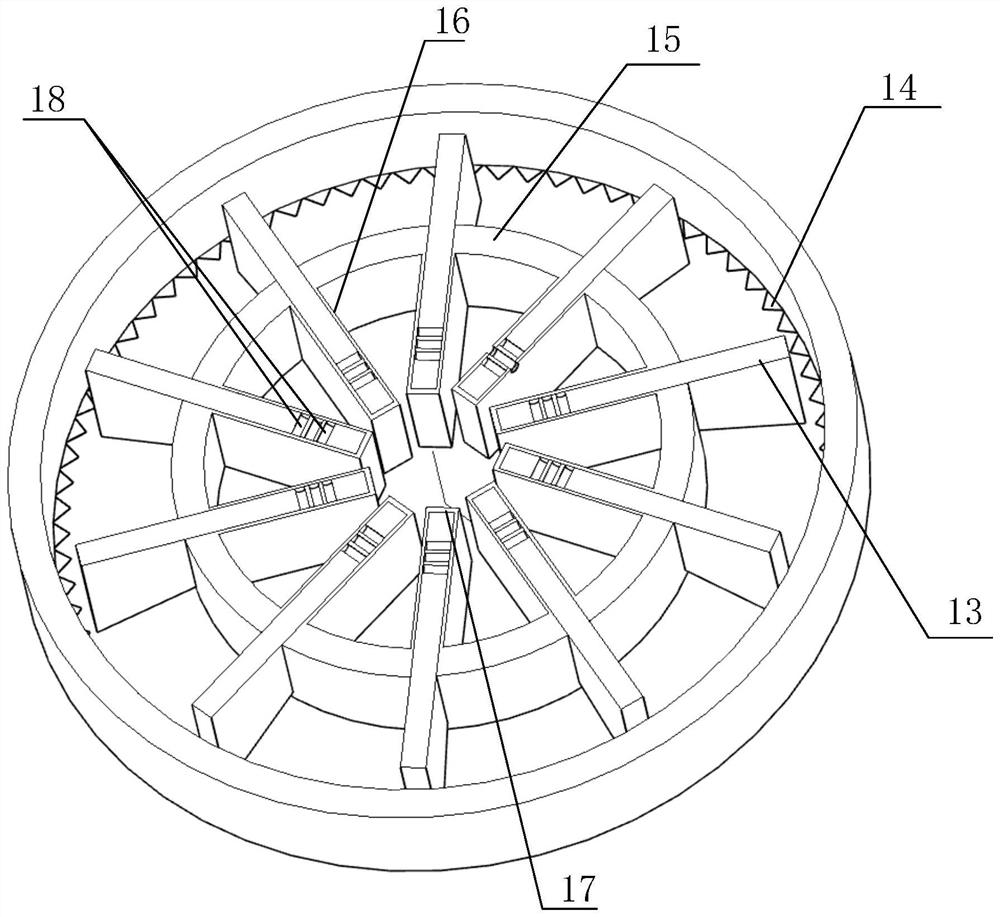

[0135] 1. Check the equipment, the blade groove is matched with the first positioning threaded hole on the blade, and the bolts are installed;

[0136] 2. Turn on the power supply, set the pre-cooling temperature to -165°C, the crushing temperature to -150°C, and connect the storage bag at the end of the discharge port;

[0137] 3. Open the liquid nitrogen valve, adjust the appropriate liquid nitrogen supply speed, and wait for the temperature to drop to the set temperature;

[0138] 4. After the temperature drops to the set temperature, add 500g of bulk PLLA particles from the upper end of the feed port, and close the feed port valve;

[0139] 5. After the temperature is stable, set the fan speed to 45 and the feeding speed to 10. At this time, the block PLLA enters the crushing bin with the feeding screw;

[0140] 6. Under the action of blades and toothed discs, the massive PLLA particles are crushed into powder;

[0141] 7. The powder enters the discharge port from the cr...

example 2

[0146] 1. Check the equipment, the blade groove is matched with the first positioning threaded hole on the blade, and the bolts are installed;

[0147] 2. Turn on the power supply, set the pre-cooling temperature to -190°C, the crushing temperature to -180°C, and connect the storage bag at the end of the discharge port;

[0148] 3. Add 500g of block PLLA particles from the upper end of the feeding port, open the valve of the feeding port, when all the block PLLA particles enter the storage bin, close the valve of the feeding port;

[0149] 4. Open the liquid nitrogen valve, adjust the appropriate liquid nitrogen supply speed, and wait for the temperature to drop to the set temperature;

[0150] 5. After the temperature is stable, set the fan speed to 45 and the feeding speed to 10. At this time, the block PLLA enters the crushing bin with the rotation of the feeding screw;

[0151] 6. Under the action of blades and toothed discs, the massive PLLA particles are crushed into po...

example 3

[0157] 1. Check the equipment, the blade groove is matched with the first positioning threaded hole on the blade, and the bolts are installed;

[0158] 2. Turn on the power, set the pre-cooling temperature to -90°C, the crushing temperature to -70°C, and connect the storage bag at the end of the discharge port;

[0159] 3. Add 500g block PGA particles from the upper end of the feed port, open the feed port valve, when the block polylactic acid PGA particles all enter the storage bin, close the feed port valve;

[0160] 4. Open the liquid nitrogen valve, adjust the appropriate liquid nitrogen supply speed, and wait for the temperature to drop to the set temperature;

[0161] 5. After the temperature is stable, set the fan speed to 45 and the feeding speed to 10. At this time, the massive PGA particles enter the crushing bin with the rotation of the feeding screw;

[0162] 6. Under the action of blades and toothed discs, the massive PGA particles are crushed into powder;

[0163...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com