Production process of double-layer composite pad

A double-layer composite, production process technology, applied in the direction of household appliances, other household appliances, household components, etc., can solve the problems of difficult trimming of semi-finished products, sore hands and even sore arms of operators, and low production efficiency. Product qualification rate and production efficiency, eliminate hand soreness, and avoid the effect of difficult trimming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

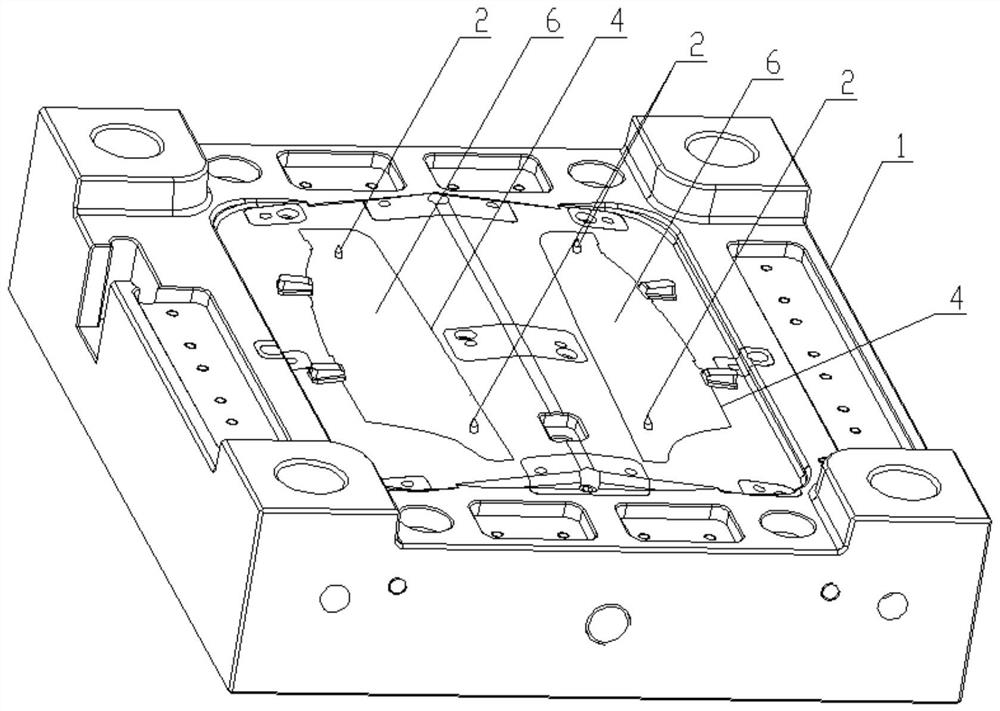

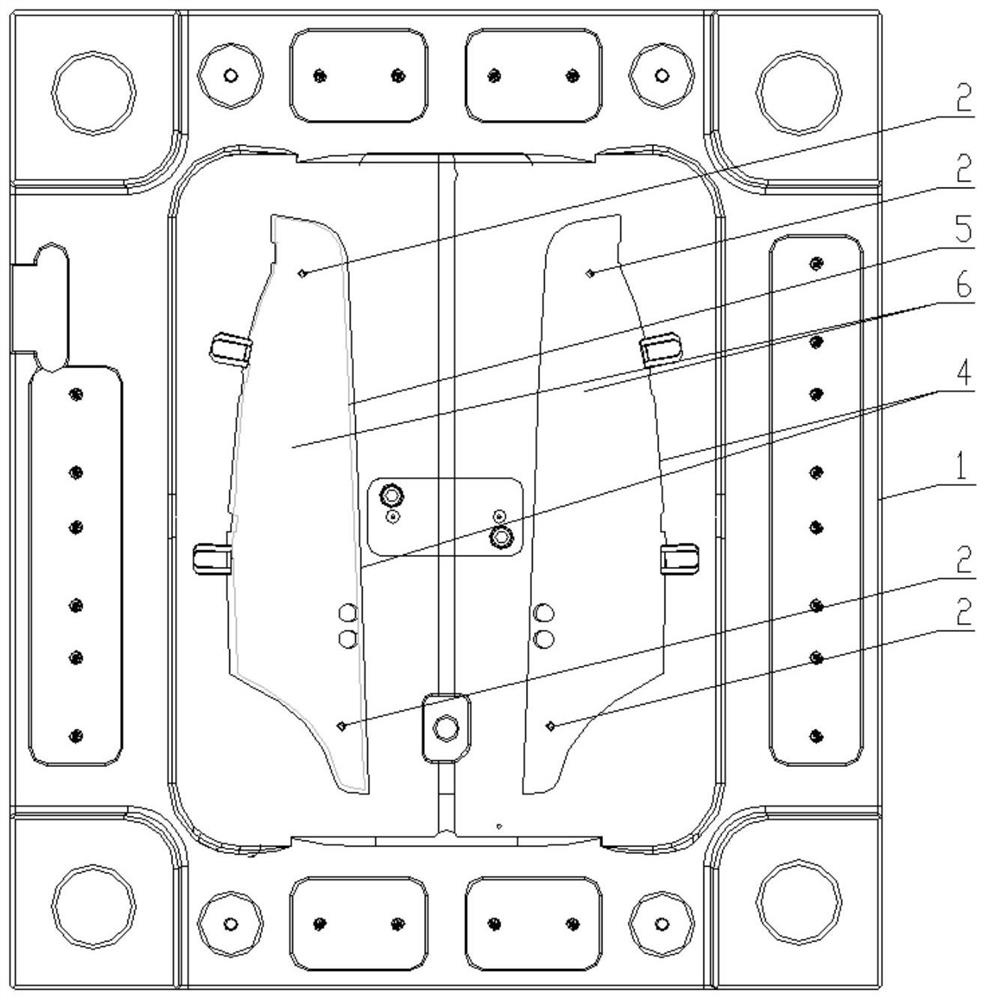

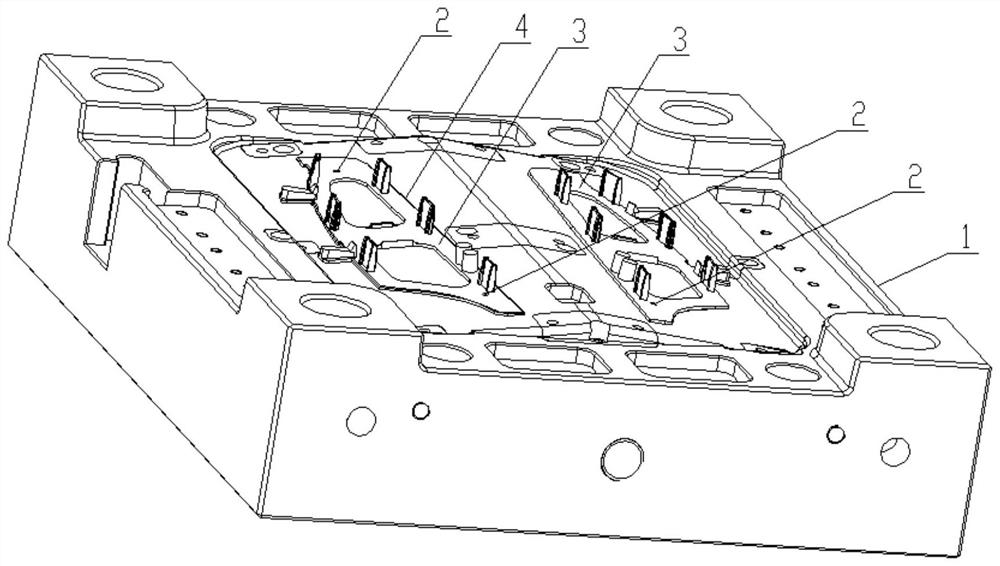

[0027] Embodiment 1: The double-layer composite pad involved in this embodiment is the car front door armrest spring pad skeleton (referred to as the product), which is composed of an injection-molded body and a non-woven fabric attached to one side of the injection-molded body; Lower die 1 and its cavity such as figure 1 , figure 2 and image 3 As shown in the figure, the mold can form two products at one time, and four needle bodies 2 are fixed on the bottom wall of the cavity. Each needle body 2 is located in another product forming area 6 . In each product forming area 6 , the two needle bodies 2 are arranged within the outer contour line 4 near the edge of the front door armrest spring pad frame 3 of the automobile, and are distributed on the upper and lower sides of the middle of the product forming area 6 . The diameter of the root of the needle body 2 is 4 mm.

[0028] In the present embodiment, the steps of the production process of the frame of the spring pad fo...

Embodiment 2

[0035] Example 2: Referring to Example 1, the main difference between it and Example 1 is that the needle body 2 in Example 1 is replaced by an inlaid needle with a specification of 5 mm.

Embodiment 3

[0036] Example 3: Referring to Example 1, the main difference between it and Example 1 is that the prepared double-layer composite pad is an automobile filter pad, specifically a filter element (primary net) of a Hyperion automobile air purifier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com