Composite core, steel wire rope and manufacturing method of steel wire rope

A production method and composite core technology, which can be used in textiles, papermaking, textile cables, etc., can solve the problems of heavy counterweight and difficulty in maintaining balance of steel wire ropes, and achieve the effect of proper weight, ensuring balance and improving structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

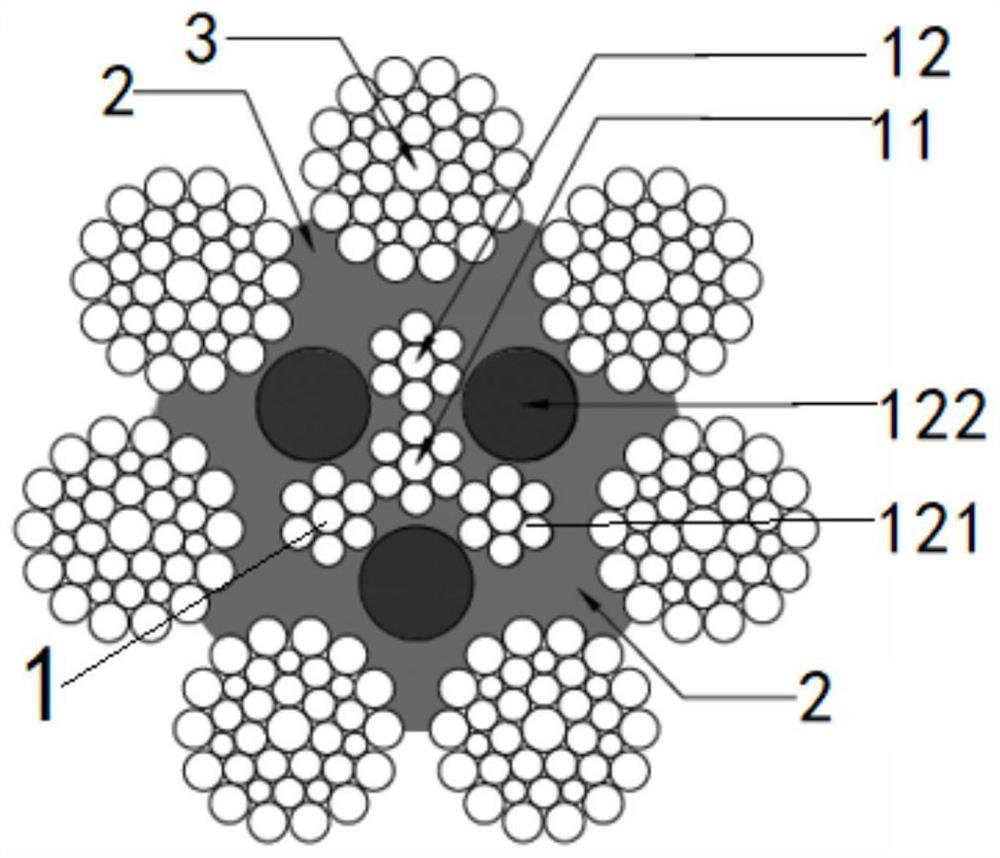

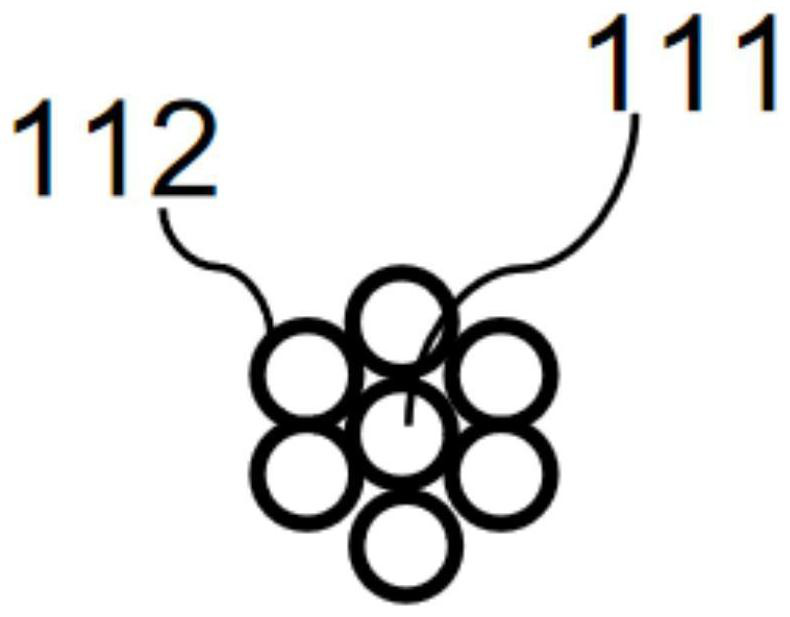

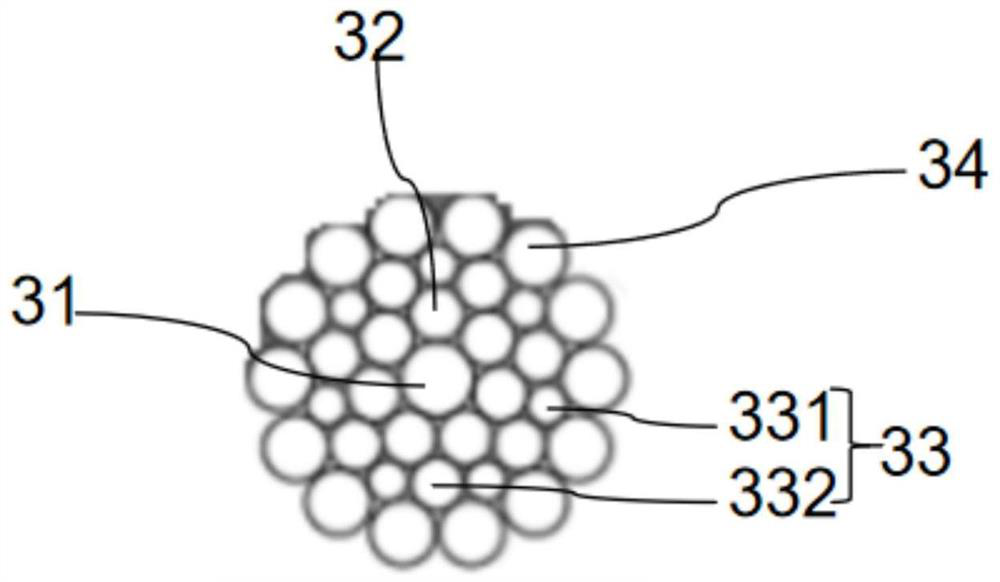

[0036] combine Figure 1-3 , this embodiment proposes a composite core 1, which includes a steel strand layer 11 and a composite layer 12 from the inside to the outside, the steel strand layer 11 is the first steel strand, and the composite layer 12 includes 3 fiber strands 122 and 3 fiber strands arranged alternately The second steel strand 121; 3 second steel strands 121 and 3 fiber strands 122 are alternately twisted around the outer surface of the first steel strand; the first steel strand or the second steel strand 121 is formed by a first central steel wire 111 and 6 second steel wires 112 are twisted to form, and 6 second steel wires 112 cover the first central steel wire 111; the diameter of the first central steel wire 111 is 2.3 mm, the diameter of the second steel wire 112 is 2.1 mm, and the fiber The diameter of strand 122 is 8.0 mm.

[0037] In addition, the present embodiment also proposes a manufacturing method of the composite core 1, comprising the following ...

Embodiment 2

[0049] The difference between this embodiment and Embodiment 1 is that the number of the third steel strands 3 is 8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com