Underground support pile glass fiber rib-reinforcement cage and connecting method thereof

A technology of glass fiber reinforcement and reinforcement cage, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering, etc., which can solve the problems that glass fiber reinforcement cannot be stably connected with steel reinforcement, and achieve stable and reliable structure, convenient use, and design Scientific and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

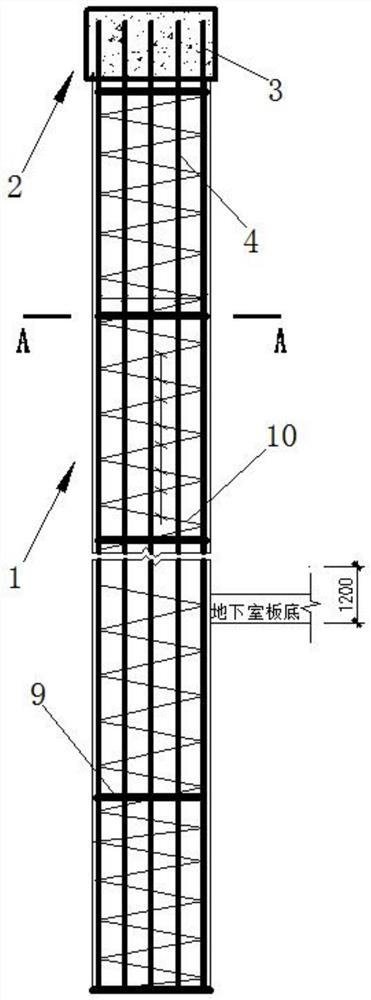

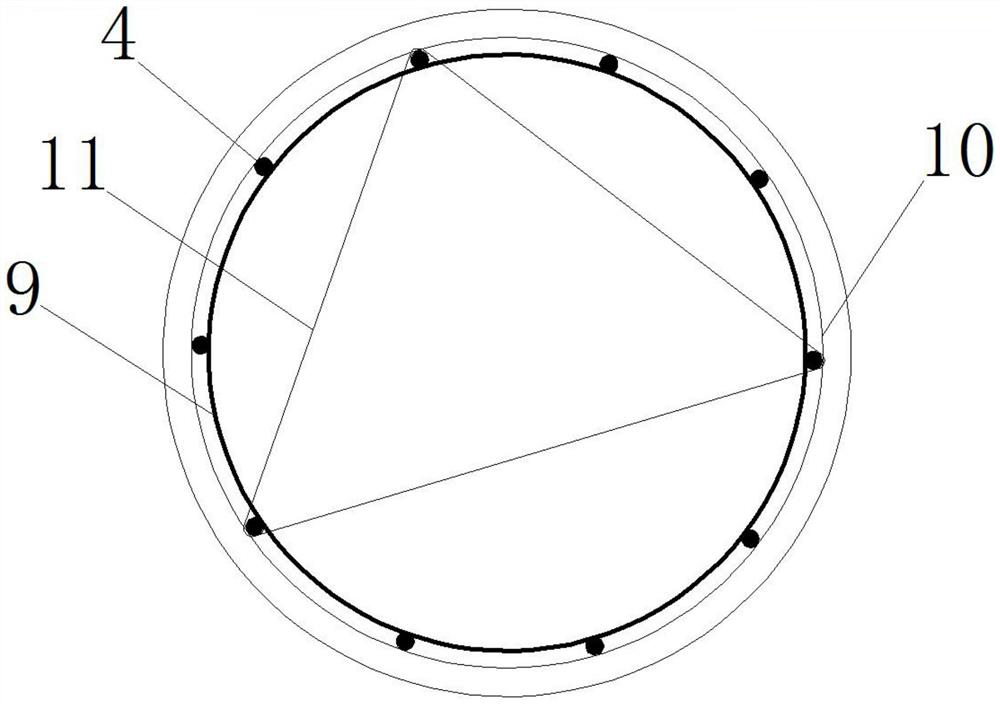

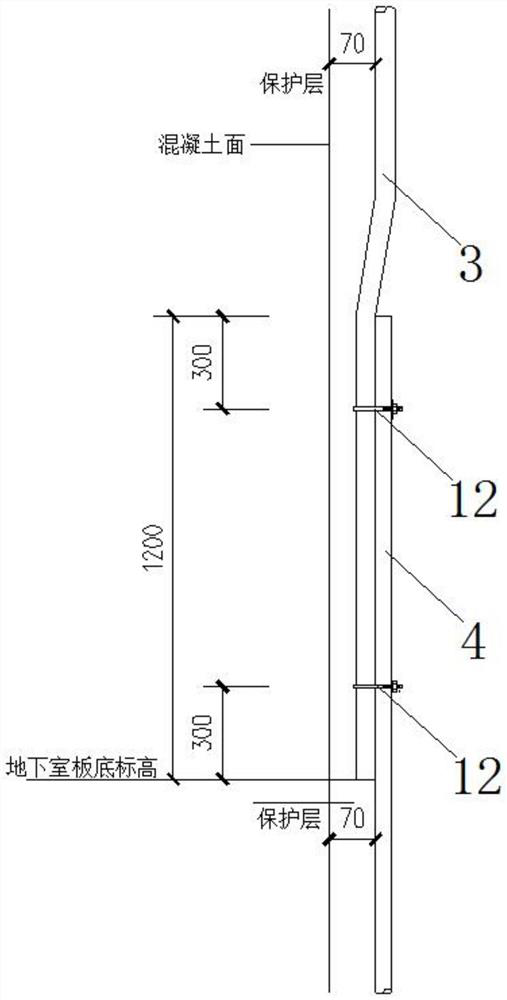

[0031] Example 1, as Figure 1-7 As shown in the figure, the present invention provides a glass fiber reinforcement-rebar cage for underground supporting piles, including a glass fiber reinforcement cage 1 erected by using glass fiber reinforcement, and a glass fiber reinforcement cage 1 erected by using steel bars and connected to the glass fiber reinforcement cage 1 The reinforcing bar cage 2; the glass fiber reinforcing bar cage 1 includes several glass fiber reinforcing bar main bars 4 uniformly distributed in the circumferential direction, annular glass fiber reinforcing bar reinforcing bars 9 connected with the glass fiber reinforcing bar main bar 4, and connecting with the glass fiber reinforcing bar main bar 4 The spiral glass fiber reinforcement stirrup 10; the main reinforcement 3 of the reinforcement cage 2 and the main reinforcement 4 of the glass fiber reinforcement are connected by a buckle mechanism.

[0032] The invention has the advantages of simple structure,...

Embodiment 2

[0033] Example 2, as Figure 1-7 As shown in the figure, the present invention provides a glass fiber reinforcement-rebar cage for underground supporting piles, including a glass fiber reinforcement cage 1 erected by using glass fiber reinforcement, and a glass fiber reinforcement cage 1 erected by using steel bars and connected to the glass fiber reinforcement cage 1 The reinforcing bar cage 2; the glass fiber reinforcing bar cage 1 includes several glass fiber reinforcing bar main bars 4 uniformly distributed in the circumferential direction, annular glass fiber reinforcing bar reinforcing bars 9 connected with the glass fiber reinforcing bar main bar 4, and connecting with the glass fiber reinforcing bar main bar 4 The spiral glass fiber reinforcement stirrup 10; the main reinforcement 3 of the reinforcement cage 2 and the main reinforcement 4 of the glass fiber reinforcement are connected by a buckle mechanism. The glass fiber reinforcement cage 1 also includes a plurality...

Embodiment 3

[0035] Example 3, as Figure 1-7 As shown in the figure, the present invention provides a glass fiber reinforcement-rebar cage for underground supporting piles, including a glass fiber reinforcement cage 1 erected by using glass fiber reinforcement, and a glass fiber reinforcement cage 1 erected by using steel bars and connected to the glass fiber reinforcement cage 1 The reinforcing bar cage 2; the glass fiber reinforcing bar cage 1 includes several glass fiber reinforcing bar main bars 4 uniformly distributed in the circumferential direction, annular glass fiber reinforcing bar reinforcing bars 9 connected with the glass fiber reinforcing bar main bar 4, and connecting with the glass fiber reinforcing bar main bar 4 The spiral glass fiber reinforcement stirrup 10; the main reinforcement 3 of the reinforcement cage 2 and the main reinforcement 4 of the glass fiber reinforcement are connected by a buckle mechanism. The glass fiber reinforcement cage 1 also includes a plurality...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com