Precise measurement test bed for special-shaped control lever of airplane and use method

A joystick and test bench technology, applied in the field of mechanical sliding mechanism measuring devices, can solve the problems of difficulty in measuring and adjusting special-shaped joysticks, low work efficiency, high error accumulation risk, etc., so as to shorten the assembly inspection cycle, improve work efficiency, The effect of reducing operator demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention and the steps are as follows:

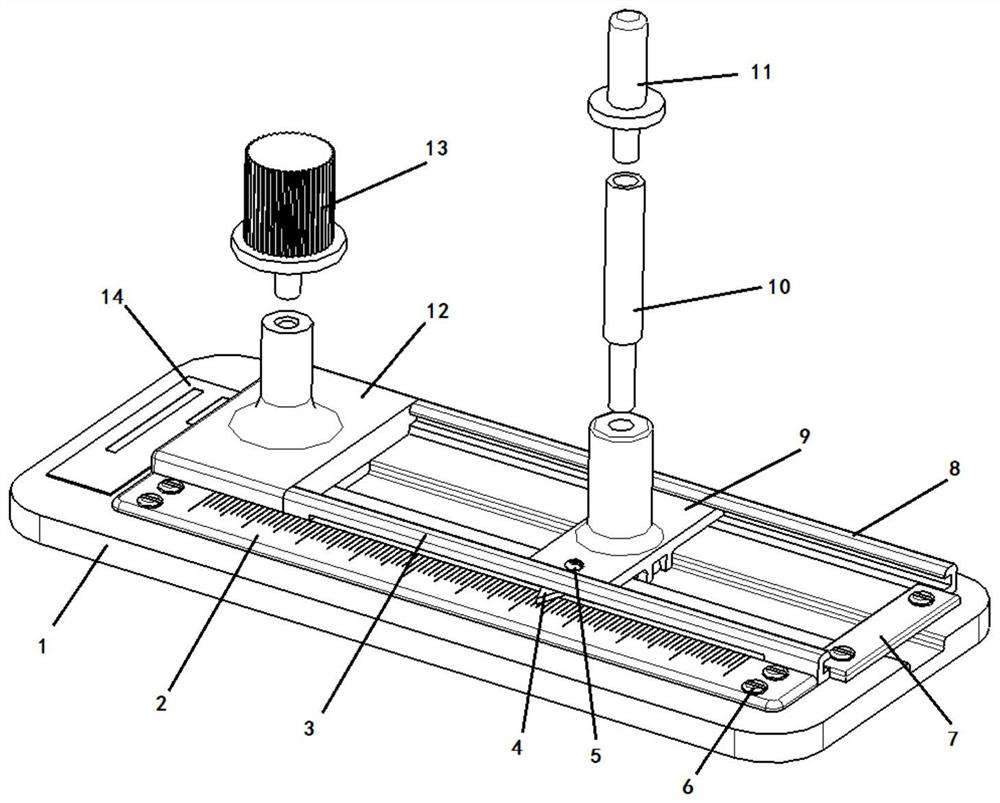

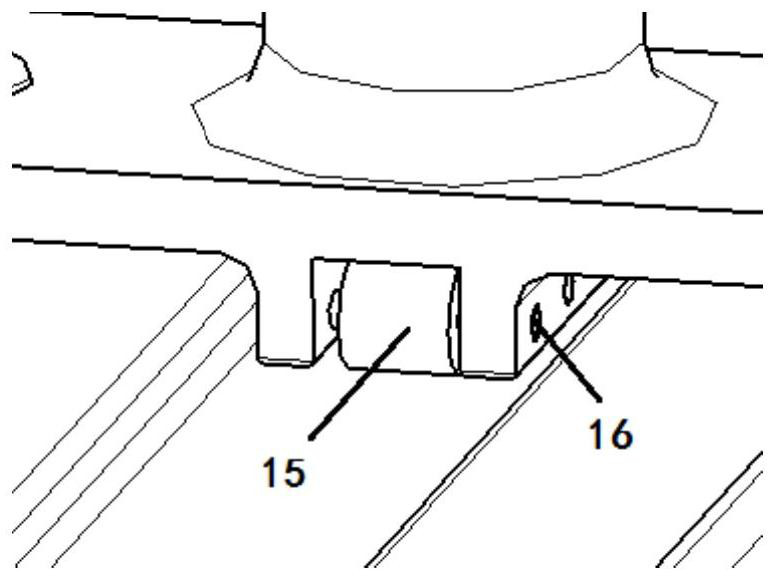

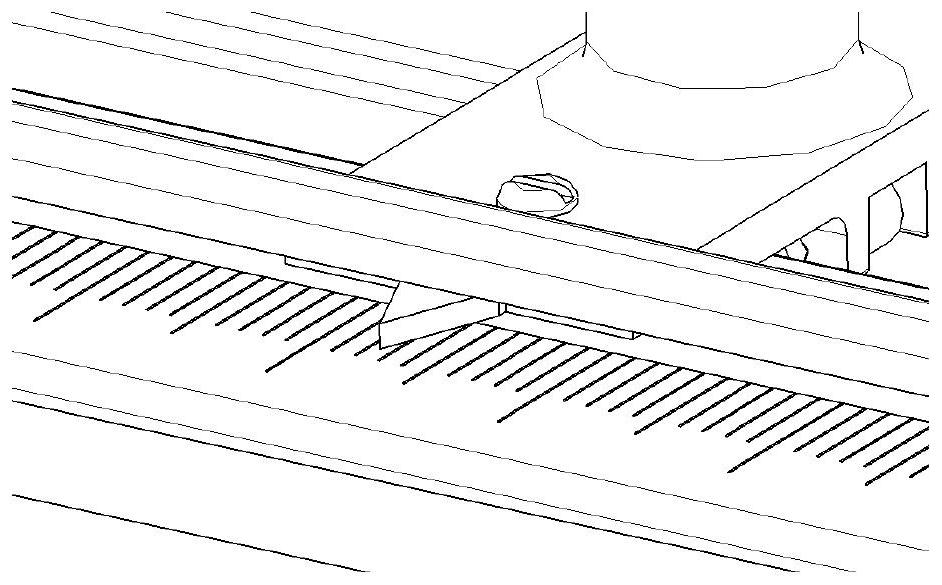

[0019] Aircraft special-shaped joystick precision measurement test bench, including equipment base 1, scale 2, grooved slide rail 3, moving pointer 4, small fixing screw 5, large fixing screw 6, base baffle 7, outer slide rail 8, sliding support The seat 9, the extension link 10, the optional joint 11, the fixed support 12, the detachable joint 13, the information sign 14, the sliding roller 15 and the roller pin 16.

[0020] The device base 1 is provided with a non-slip pad, which can be placed on the tool table smoothly without relative sliding; the fixed support 12 is provided with a freely replaceable detachable joint 13, and the sliding support 9 There are optional joints 11 that can be freely selected according to the fixed form of the tie rod to be measured, and extended connecting rods 10 of different lengths can be freely installed on the fixed support 12 and / or the sliding suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com