Crimping type IGBT (Insulated Gate Bipolar Translator) module packaging device

A module packaging and crimping technology, which is applied to semiconductor/solid-state device components, semiconductor devices, electrical components, etc., can solve the problems of cumbersome operation, inconvenient maintenance of IGBT sub-modules or IGBT modules, and inconvenient wiring of terminal blocks. To achieve the effect of convenient installation and disassembly, convenient wiring and dismantling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

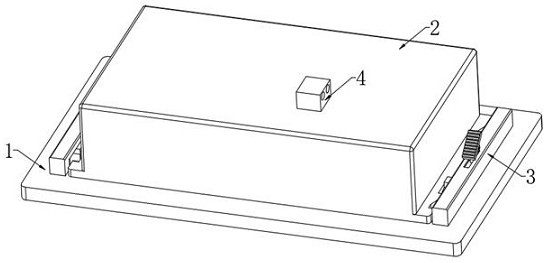

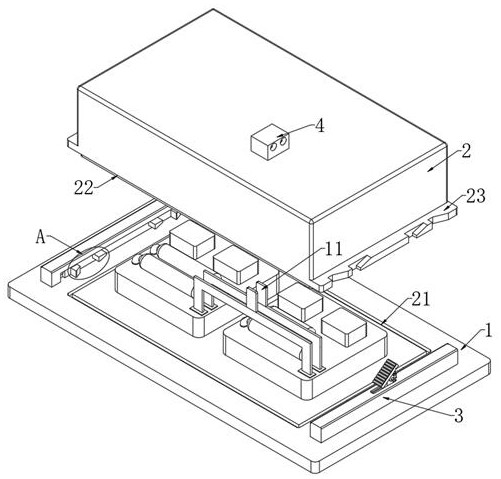

[0028] Example 1, as Figure 1-Figure 6 As shown, a crimping IGBT module packaging device proposed by the present invention includes a substrate 1, an IGBT sub-module is arranged on the upper side of the substrate 1, and an outer casing 2 that can cover the IGBT sub-module is mounted on the substrate 1. The outer casing The lower side of 2 is fixed with a circular frame block 22, and the upper side of the base plate 1 is provided with a circular frame slot 21 which is adapted to the circular frame block 22. The position of 2 is positioned, and at the same time, the sealing between the casing 2 and the substrate 1 is increased. The IGBT sub-module is provided with a conductive terminal 11 for energization. The conductive terminal 11 is made of hard conductive material, and both sides of the casing 2 are fixed. There is a pressing plate 23, and a pressing and fixing mechanism 3 capable of pressing and fixing the pressing plate 23 is installed on the base plate 1;

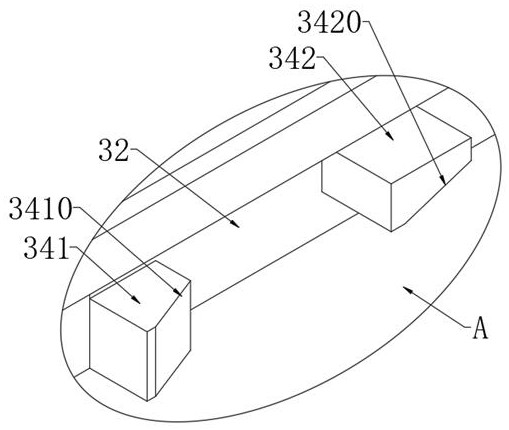

[0029] The p...

Embodiment 2

[0034] Example 2, as figure 1 , figure 2 as well as Figure 7 As shown, in a crimping IGBT module packaging device proposed by the present invention, compared with the first embodiment, a wiring mechanism 4 corresponding to the conductive terminals 11 is fixed on the upper side of the casing 2 in this embodiment. The mounting block 41 at the upper end of the housing 2 is provided with two inner holes 42 for inserting wires on one side of the mounting block 41 , and an inserting through hole communicating with the interior of the casing 2 is formed on the lower side of the inner hole 42 for the inserting wire, and the inserting through holes are connected with the conductive terminals 11 The upper end of the conductive terminal 11 can be inserted into the insertion through hole, and the lower side of the inner hole 42 of the plug-in wire is connected with a receiving groove 43. The receiving groove 43 is provided with a conductive extrusion arc plate 44. The conductive extrus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com