Rigid-flex circuit board preparation method and prepared circuit board

A soft-rigid combination, circuit board technology, applied in circuit substrate materials, printed circuit manufacturing, structural connection of printed circuits, etc., to achieve the effect of ensuring stability and ensuring bendability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

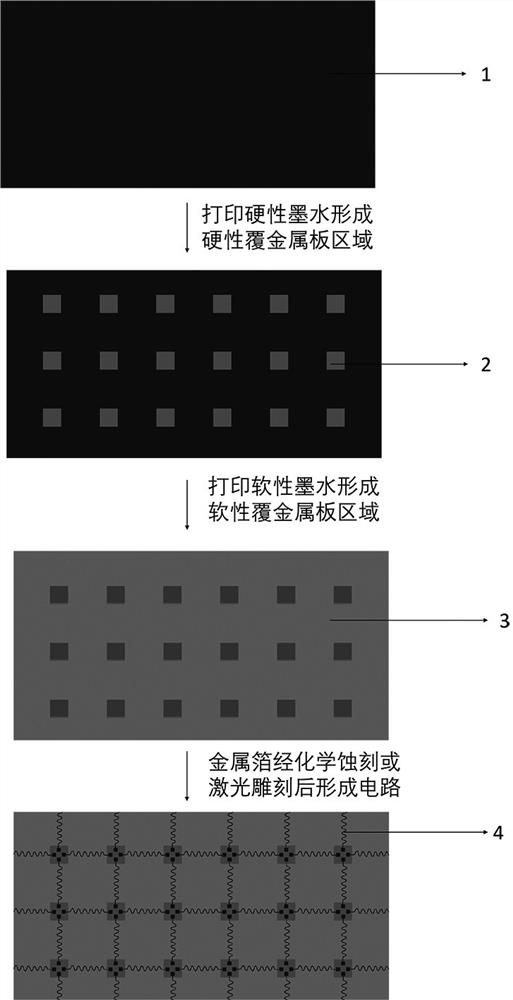

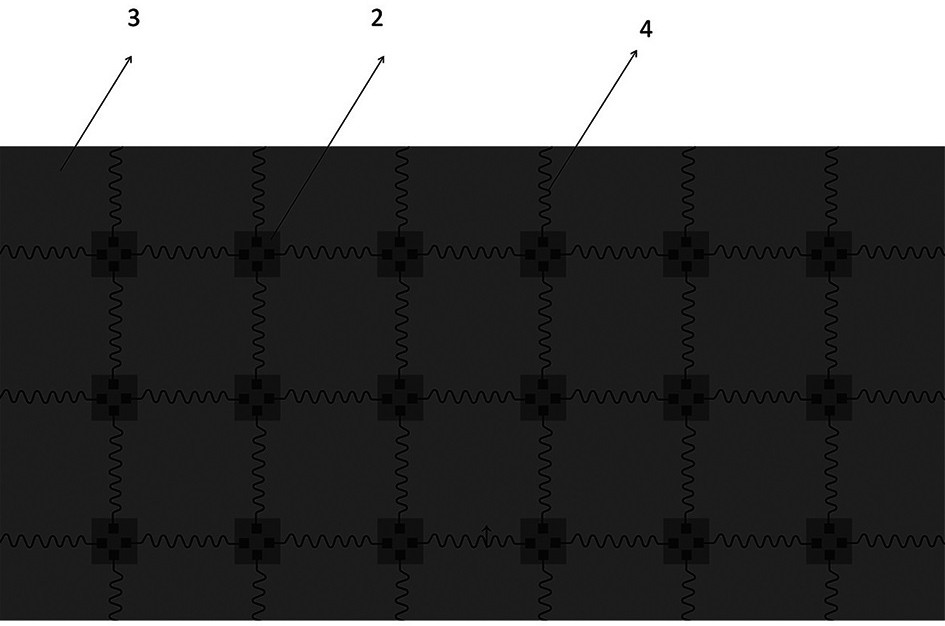

[0026] A method for preparing a single-layer flexible-rigid circuit board, figure 1 It is a schematic diagram of a method for preparing a flexible-rigid circuit board according to Embodiment 1 of the present invention, which includes the following steps:

[0027] (1) According to the distribution pattern of the hard area designed by the circuit board, inkjet print the hard ink on the surface of the copper foil 1 and use a 395nm UV lamp to cure; The hard ink and the soft ink are printed on the same side of the copper foil 1.

[0028] (2) After the hard ink of inkjet printing is cured, a rigid metal-clad plate area is formed, and the rigid area is the component bonding and fixing area; the rigid material substrate 2 formed after the hard ink is cured by light is not easily deformed; the softness of inkjet printing After the ink is cured, a flexible metal clad plate area is formed, and the soft area is a circuit conduction area. The flexible material substrate 3 formed by the th...

Embodiment 2

[0033] A method for preparing a multilayer flexible-rigid circuit board, comprising the following steps:

[0034] Make a 3-layer circuit board, each layer of circuit pattern is different, combined into a complete multi-layer circuit board.

[0035] (1) According to the pre-designed hard area distribution pattern of the first layer of circuit board, inkjet print hard ink on the surface of the aluminum foil and use a 365nm UV lamp to cure; The soft ink is inkjet printed and cured by heat; the hard ink and the soft ink are printed on the same side of the aluminum foil.

[0036] (2) The hard ink for inkjet printing forms a hard metal-clad plate area after curing, and the hard area is the component bonding and fixing area; the hard material substrate formed by the hard ink after light curing is not easy to deform; the soft ink for inkjet printing After curing, a soft metal clad plate area is formed, and the soft area is a circuit conduction area. The flexible material substrate fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com