Internally heating puffing machine

An extruder and internal heating technology, applied in food forming, food science, application, etc., can solve the problems of polluted environment, low thermal efficiency, loose and complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

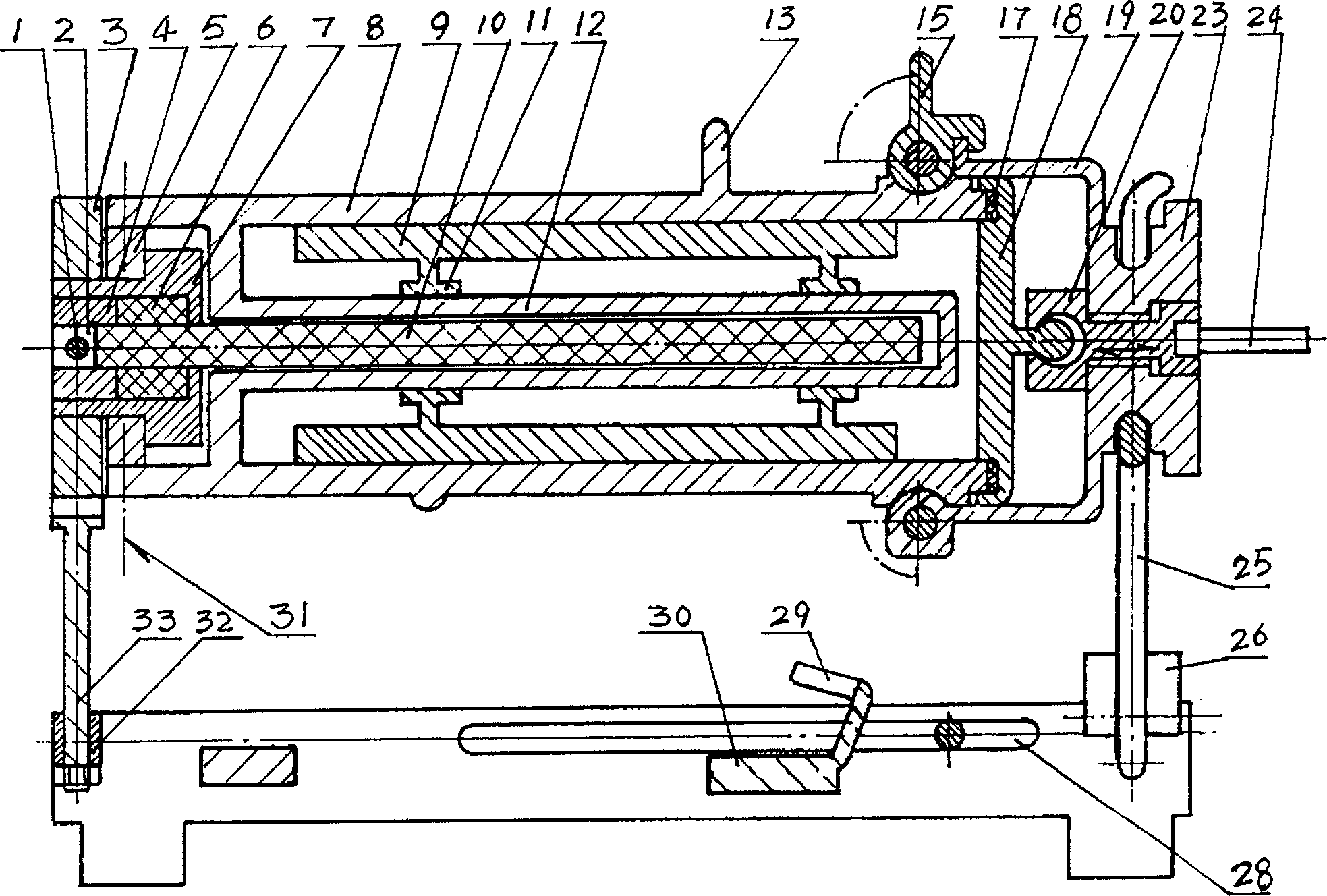

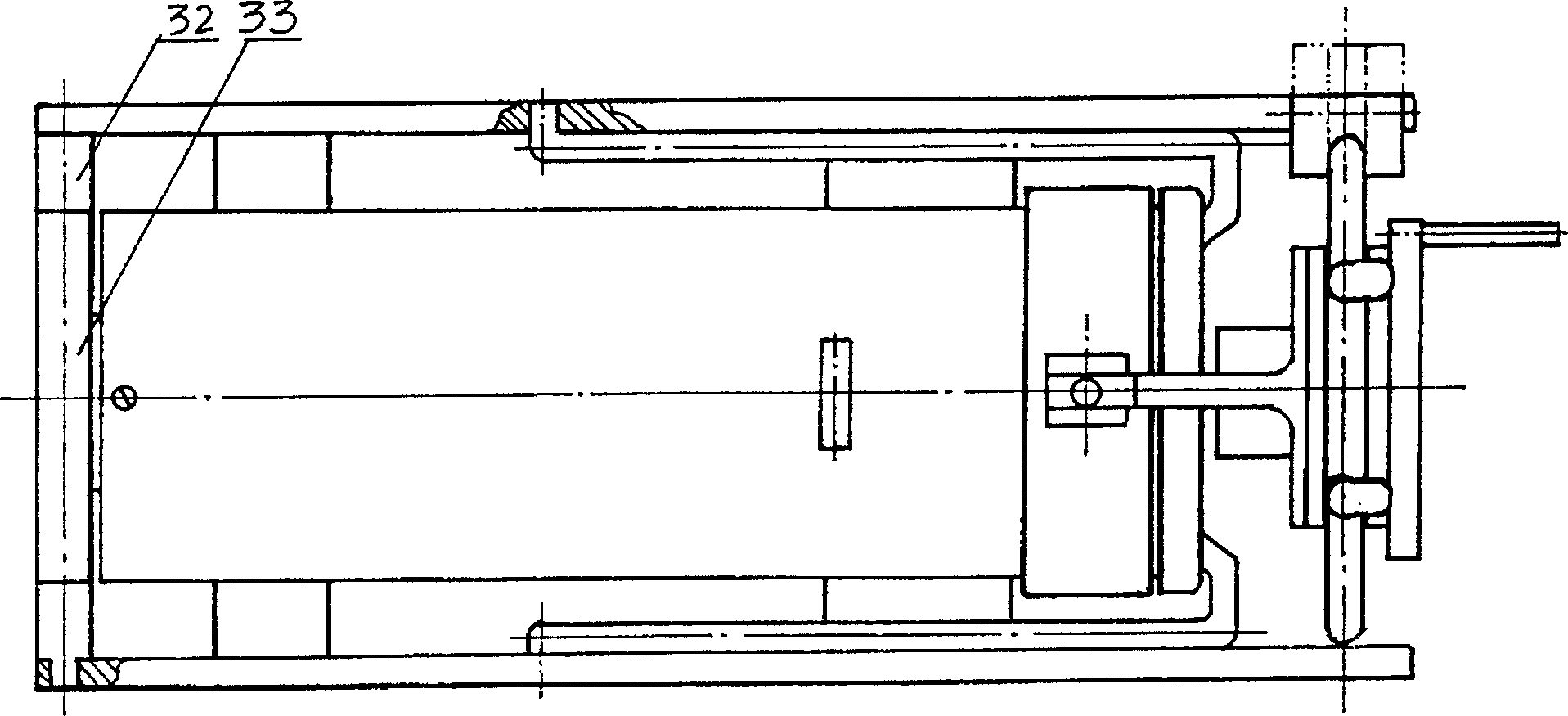

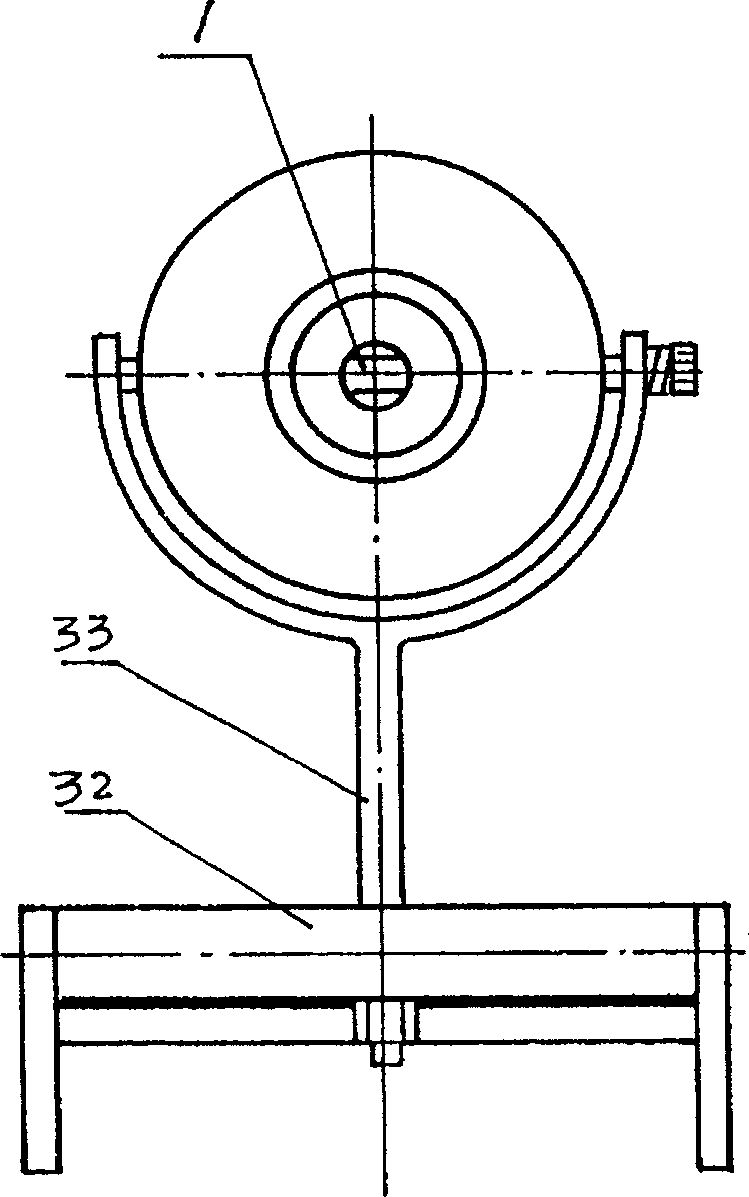

[0017] refer to figure 1 , figure 2 , image 3 , Fig. 4, hollow shaft 7, outer ring 3, shaft chamber plug 4 are fixed together by pin 1. The inner ring 5 is looped on the middle section of the hollow shaft 7 , and the drum body 8 provided with a T-shaped handle 13 is fixedly mounted on the inner ring 5 by bolts 31 . The charged wire end of the electric heating rod 10 inserted in the inner cavity of the bottom 12 of the tube is contained in the transition mechanism formed by the hollow shaft 7, the outer ring 3, the inner ring 5, the shaft cavity plug 4, and the heat insulation sleeve 6. Because the electric heating rod 10 is mainly held by the heat insulating sleeve 6, the heat loss caused by heat conduction can be reduced, and the thermal efficiency of the whole machine can be improved. If necessary, a slip ring made of spring-like parts can be looped on the electric heating rod 10, so that the heat conduction between the rod 10 and the bottom 12 can be more effectively c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com