Composition exhibiting reversible color change and exterior parts for clock using same

A color-changing composition and watch technology, applied in the direction of nanotechnology for materials and surface science, color-changing fluorescent materials, time-indicating mechanical devices, etc., can solve the problem that photochromic molecules are not suitable for long-term storage and color change time is long , Incomplete reversibility of color change, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0035] Thus, the present invention can be more fully elucidated by referring to the accompanying drawings. Figure 5 is a cross-sectional view showing a watch dial in one embodiment of the present invention. Such as Figure 5 As shown in , a base metal plating layer 2 is formed on a dial substrate 1 made of brass or nickel silver. The finishing layer 3 is then formed by finishing plating or coating. Also, to improve the efficiency of color change, the white layer 4 may be partially used as a base pattern by screen printing, and the discoloration layer 5 may be formed on the upper surface of the white layer 4 by screen printing. Furthermore, a smaller form 6 is formed on the finishing layer 6 and a dial support 7 is formed on the lower surface of the dial substrate 1 .

[0036] In this case, the discoloration layer 5 can be formed as follows.

[0037] To 50 parts by weight of thermosetting transparent ink made of epioxymelamine as the main component, add 50 parts by weight ...

example 2

[0041] Then, with Nd 2 o 3 Fine particles illustrate an example of the present invention. To 50 parts by weight of thermosetting transparent ink made of epioxymelamine as the main component, add 50 parts of Nd with an average particle size of about 7 microns 2 o 3 Fine particles, then fully stirred, so that the Nd 2 o 3 Fine particles are well dispersed in transparent ink. In this case, an appropriate amount of a solvent made of ethylene glycol monobutyl ether as a main component may be added thereto to control the viscosity. Using the above ink, screen printing can be applied on the upper surface of the white layer 4 of the dial, and the printed layer is cured at 150° C. for 30 minutes, and then dried to form a color-changing layer 5 with a thickness of 70 microns.

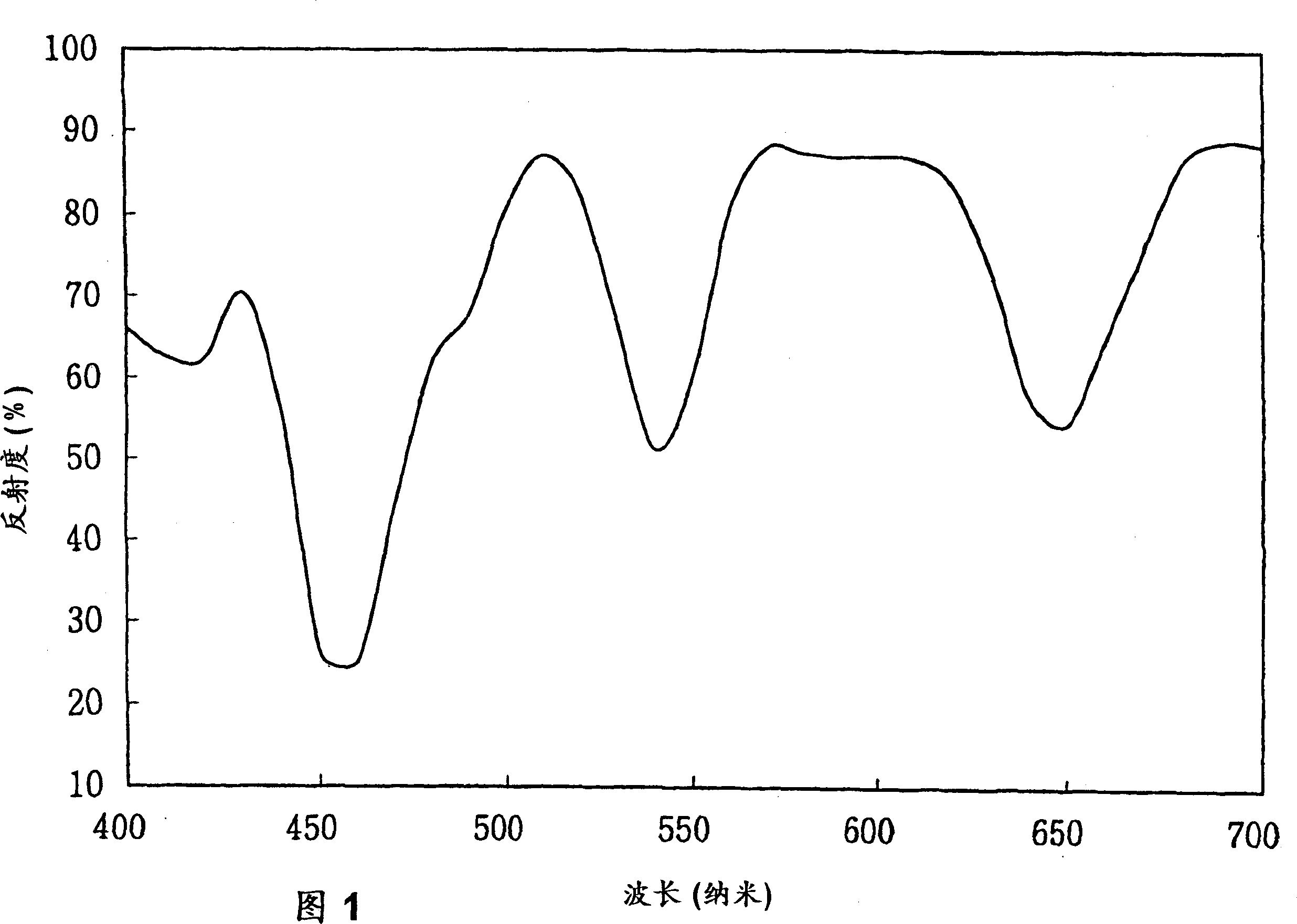

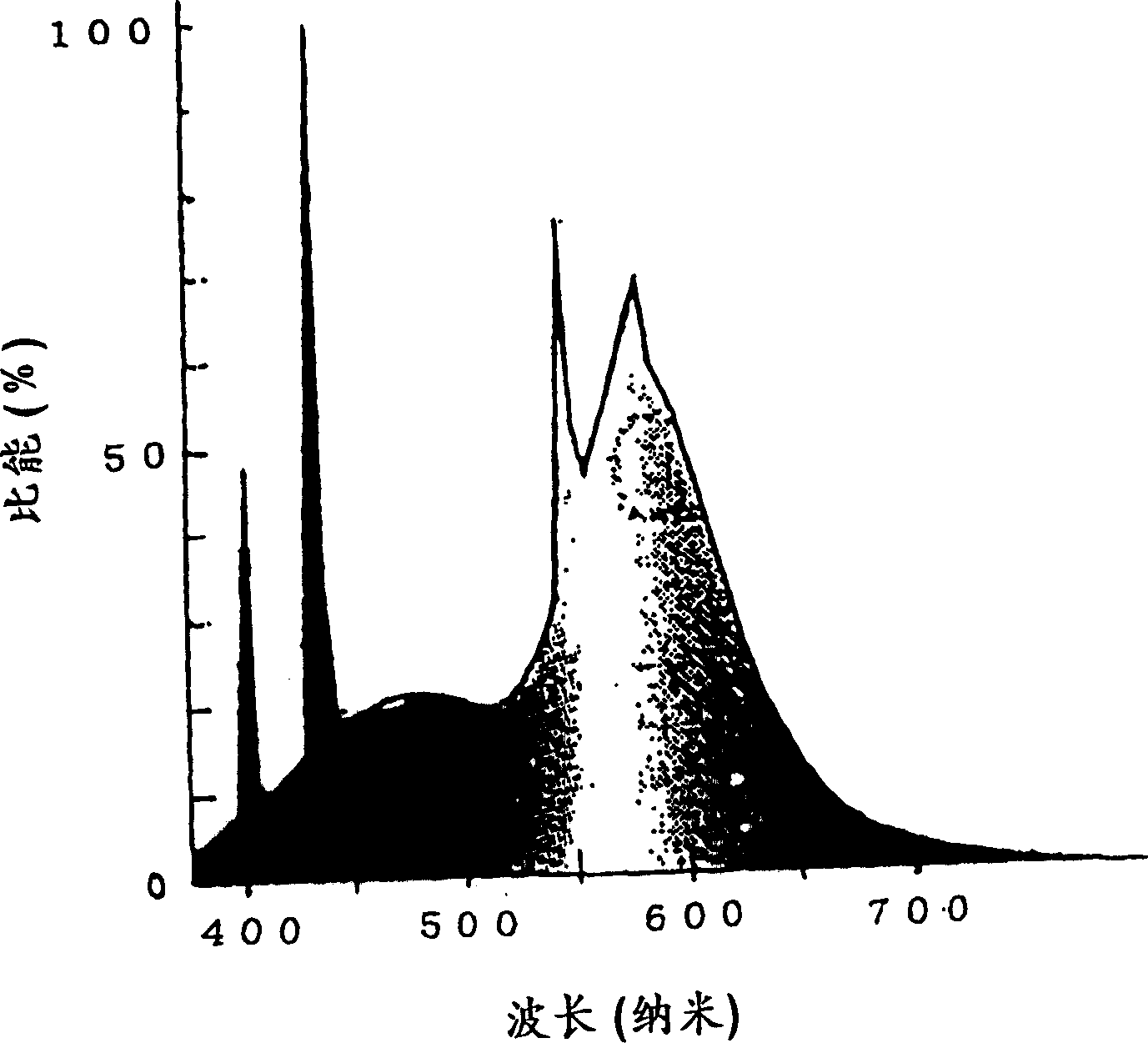

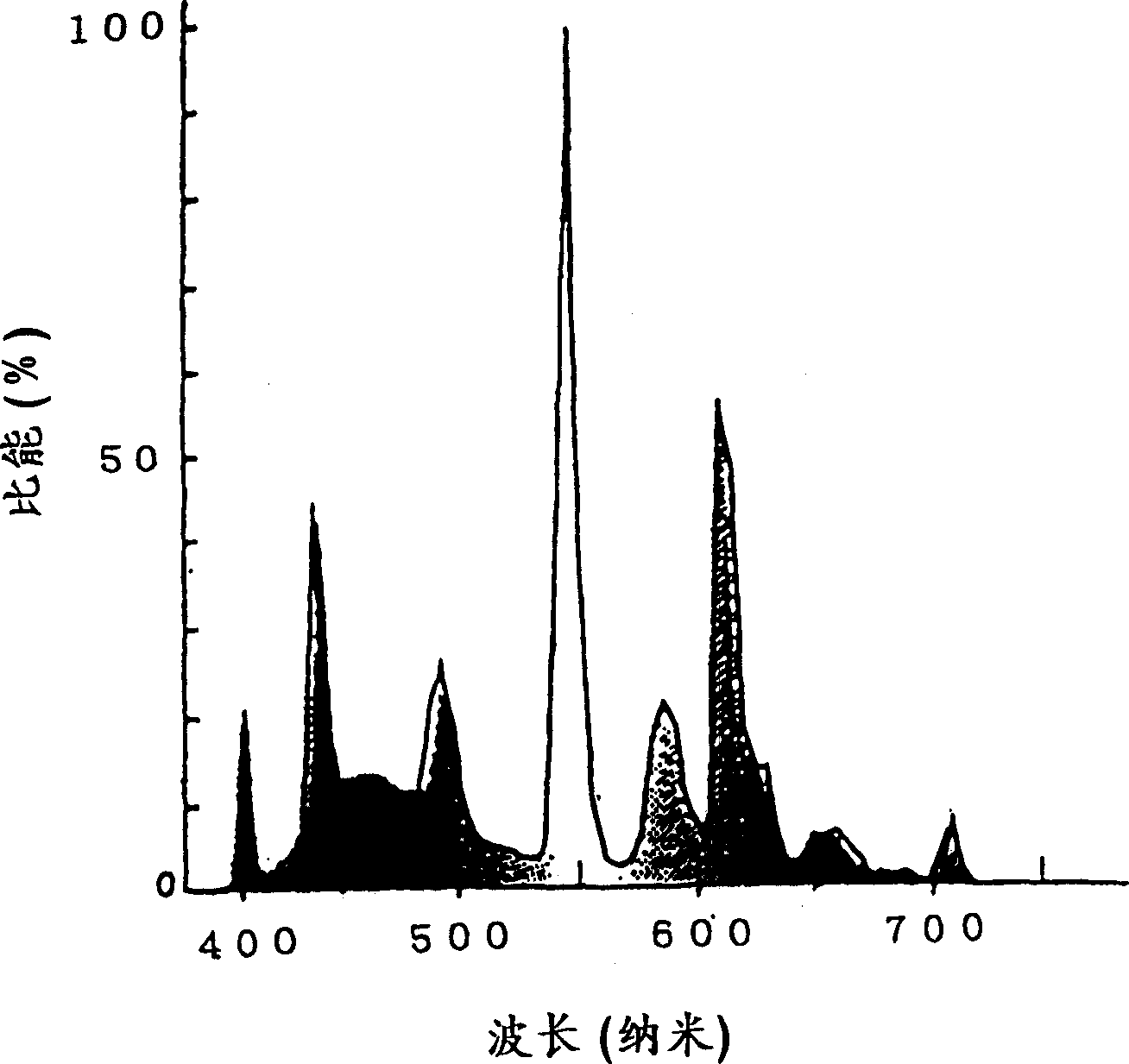

[0042] The upper surface of the dial formed by the above construction method is illuminated by each of the three light sources, namely sunlight, standard light source D 65 For example, highly color reprodu...

example 3

[0044] Then, with Pr 2 o 3 Fine particles show an example of the present invention. In 50 parts by weight of thermosetting transparent ink made of epioxymelamine as the main component, add 50 parts by weight of Pr with an average particle size of about 10 microns 2 o 3 Fine particles, followed by thorough stirring, so that Pr 2 o 3 Fine particles are well dispersed in this transparent ink. In this case, an appropriate amount of a solvent made of ethylene glycol monobutyl ether as a main component may be added thereto to control the viscosity. With the inks described above, screen printing can be applied on the upper surface of the white layer 4 of the dial. The printed layer is melted and baked at 150° C. for 30 minutes for aging treatment, and then dried to form a color-changing layer 5 with a thickness of 70 microns.

[0045] The upper surface of the dial formed by the above construction method is illuminated with each of the three light sources, namely sunlight, stan...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap