Superposed processing method for wood fibre board

A technology of wood fiber board and processing method, which is applied in the direction of wood processing equipment, wooden veneer joint, manufacturing tools, etc., and can solve the problems of wood cracking, expansion, and unusable MDF boards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

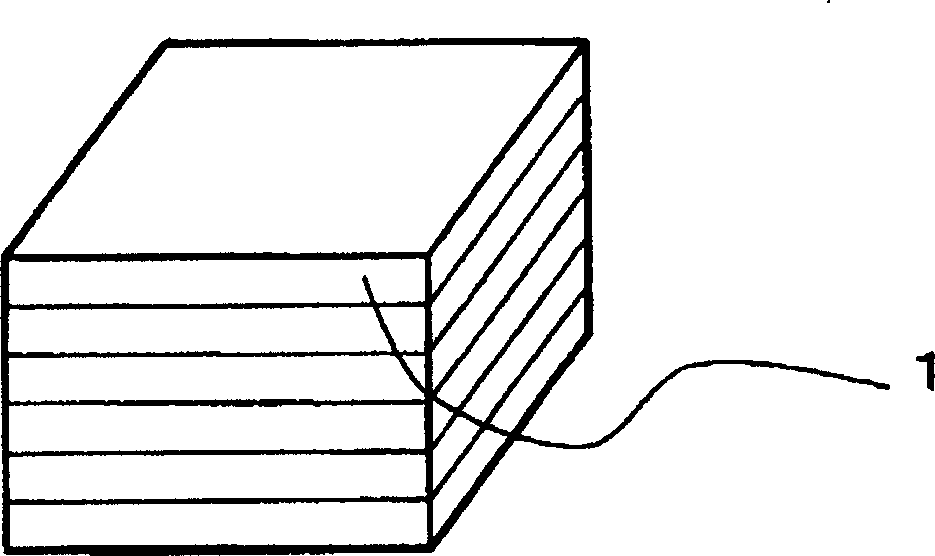

[0039] figure 1 It is an embodiment in which a plurality of wood fiber boards 1 are stacked horizontally.

no. 2 Embodiment

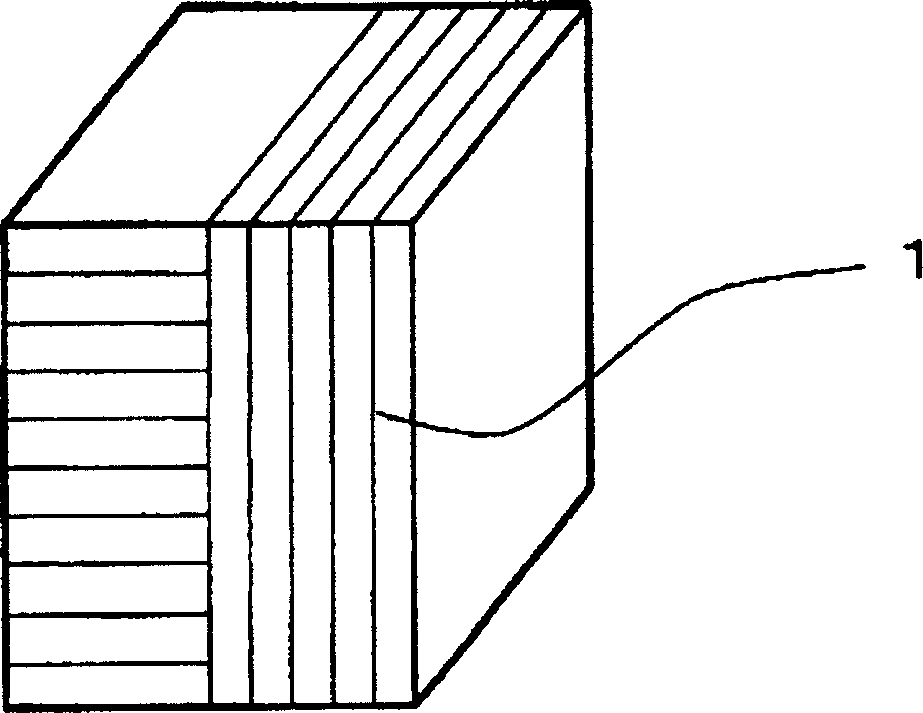

[0041] figure 2 This is an example in which a product in which wood fiber boards 1 are stacked in the horizontal direction and a product in which water quality fiber boards 1 are stacked in the vertical direction are bonded to the side.

no. 3 Embodiment

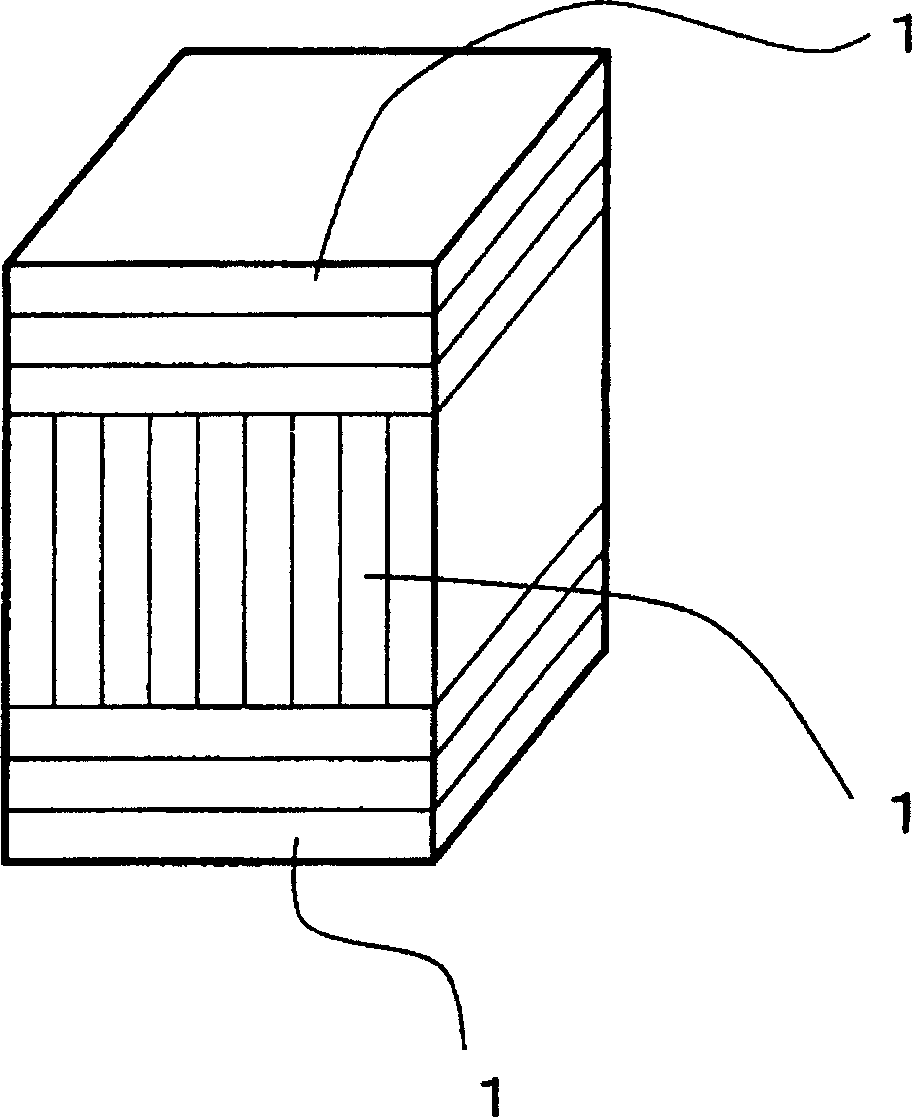

[0043] image 3 This is an embodiment in which a product in which wood fiber boards 1 are stacked in the horizontal direction and a product in which wood fiber boards 1 are stacked in the vertical direction are integrally bonded up and down. This embodiment is formed of 3 layers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com