Colour-mixing L-shaped combined prism

A prism and L-shaped technology, which is applied in the field of color separation and color combination system, can solve the problems of low yield, high price, and difficulty in ensuring that four right-angled ridges are closely connected and seamlessly integrated into one, etc., and achieves simple structure and flexible combination. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

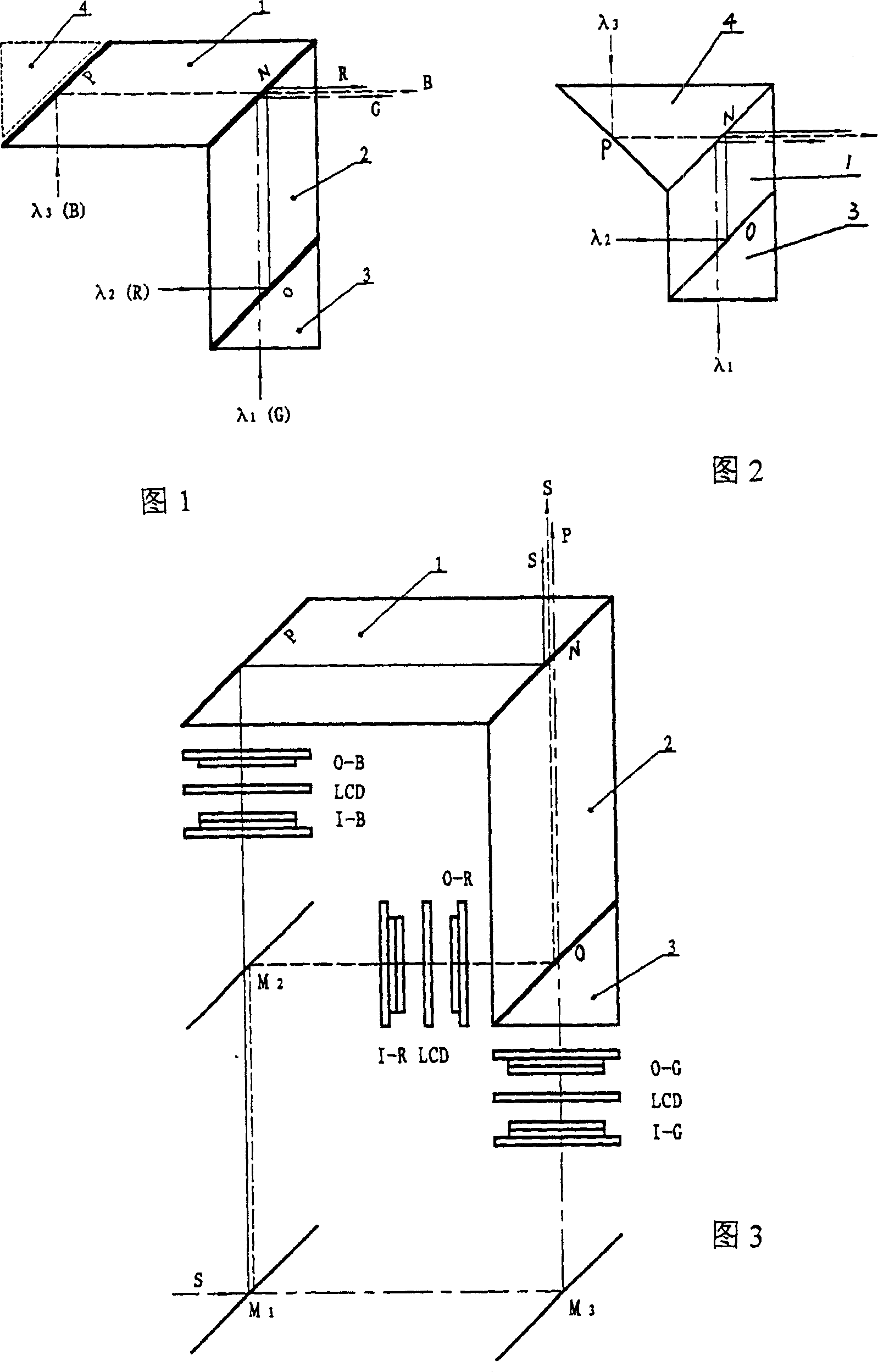

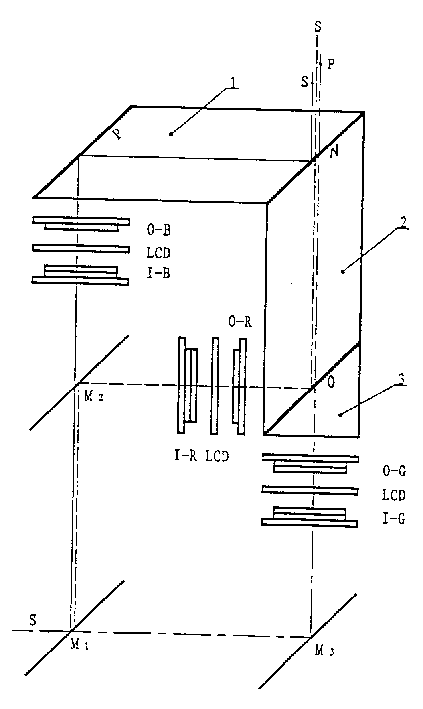

[0021] Fig. 1 is a schematic diagram of the structure of the quasi-L type color combination prism of the present invention.

[0022] As shown in the figure, the quasi-L-shaped color combination prism of the present invention is formed by gluing two parallelogram prism columns 1 and 2 and a right-angled triangular prism column 3 . The gluing surface N of two parallelogram prism columns 1 and 2 is the main color combination surface of the three color channels R, G, and B in the optical engine, and the gluing surface O of the parallelogram prism column 2 and the right-angled triangular prism column 3 is the optical The auxiliary color combining surface of the two color channels R and G in the engine, and the other working surface P of the parallelogram prism column 1 is a reflective surface, which reflects the light beam of another color channel B in the optical engine.

[0023] If the right-angled triangular prism column 4 is also glued on the P working surface of the parallelog...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap