Method for fabricating low-loss optically active device

An active device, optical technology, applied in the direction of optical components, coupling of optical waveguides, instruments, etc., can solve the problems of unfavorable device injection loss, increased total device injection loss, and high optical loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

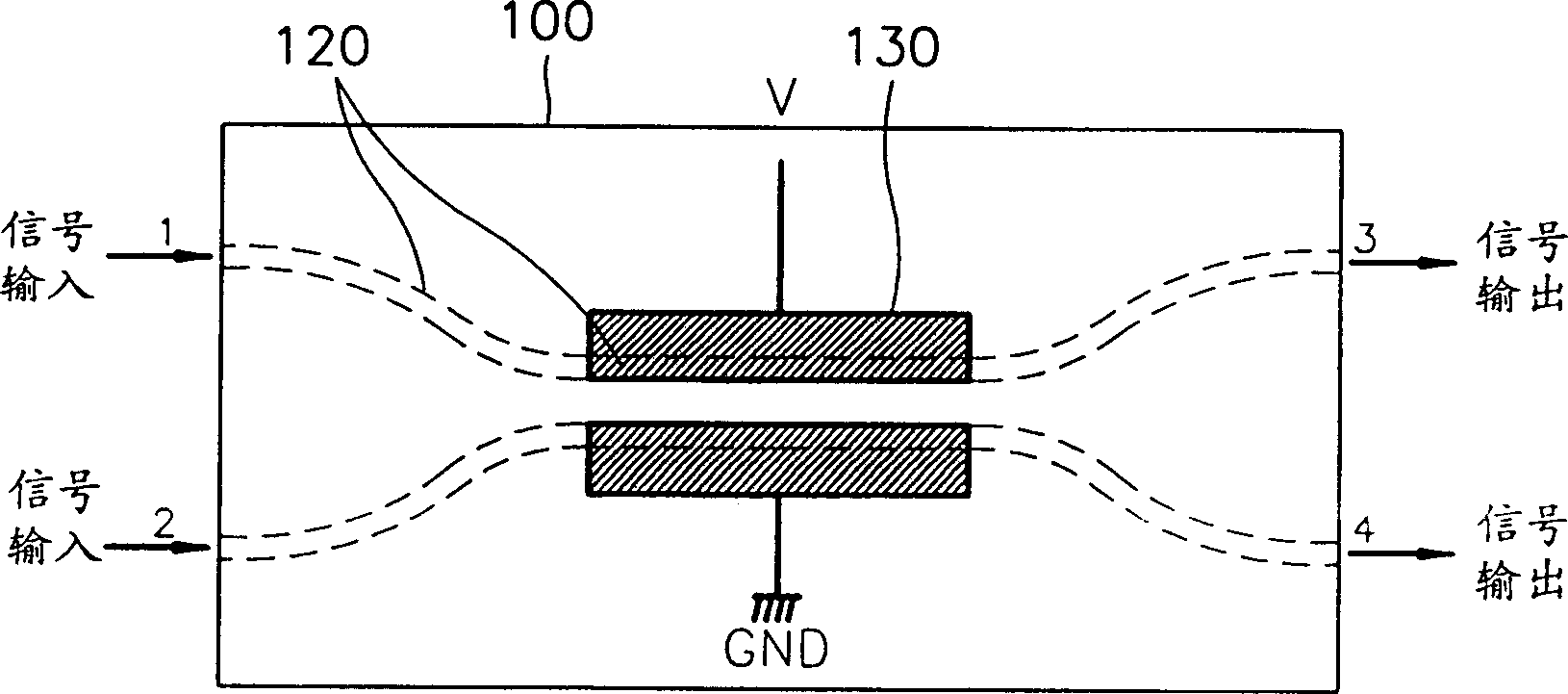

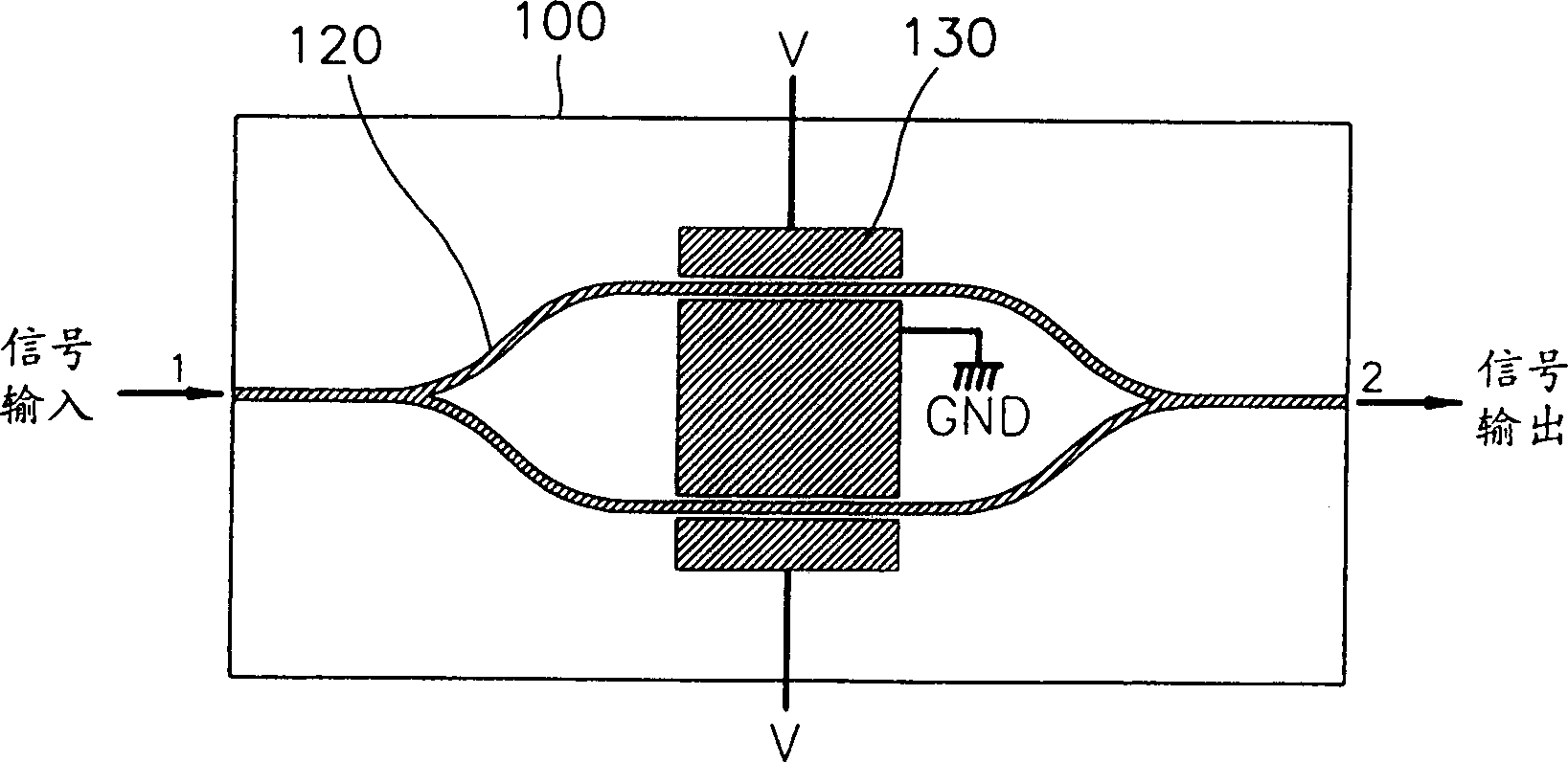

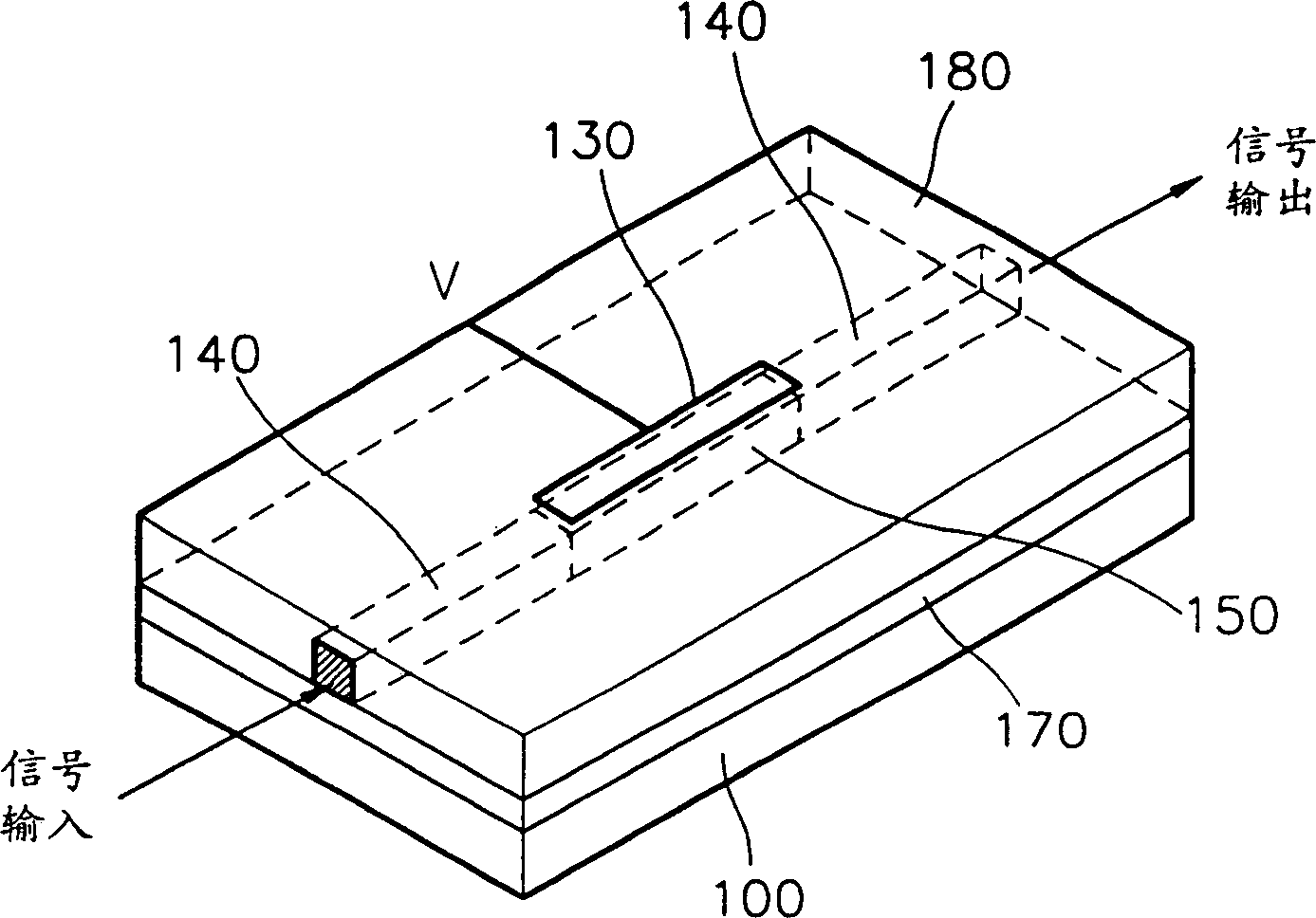

[0029] see figure 2 , the low-loss active device of the present invention is constituted like this: the optical waveguide inner core is made of linear optical polymer and nonlinear optical polymer, the electrode and the optical waveguide inner core that are made of nonlinear optical polymer The formation of regions in the source device where nonlinear interactions occur. The optical active device comprises: a substrate 100; a lower cladding layer 170 arranged on the substrate 100; optical waveguides (140 and 150) for waveguide optical signals arranged on the lower cladding layer 170, which are respectively required non- The nonlinear inner core region 150 of linear action and the linear inner core region 140 that does not require nonlinear action; the upper cladding layer 180 disposed on the optical waveguide (140 and 150) and the lower cladding layer 170; and the nonlinear inner core disposed on electrodes 130 on the area. The nonlinear core region 150 is located between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com