Process for composite solvent for separating arylhydrocarbon by extraction and distillation

A technology of extractive distillation and compound solvent, which is applied in the directions of distillation purification/separation, extractive distillation, azeotropic/extractive distillation, etc. It can solve the problems of high operating severity of the recovery tower and the temperature of the recovery tower should not be too high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

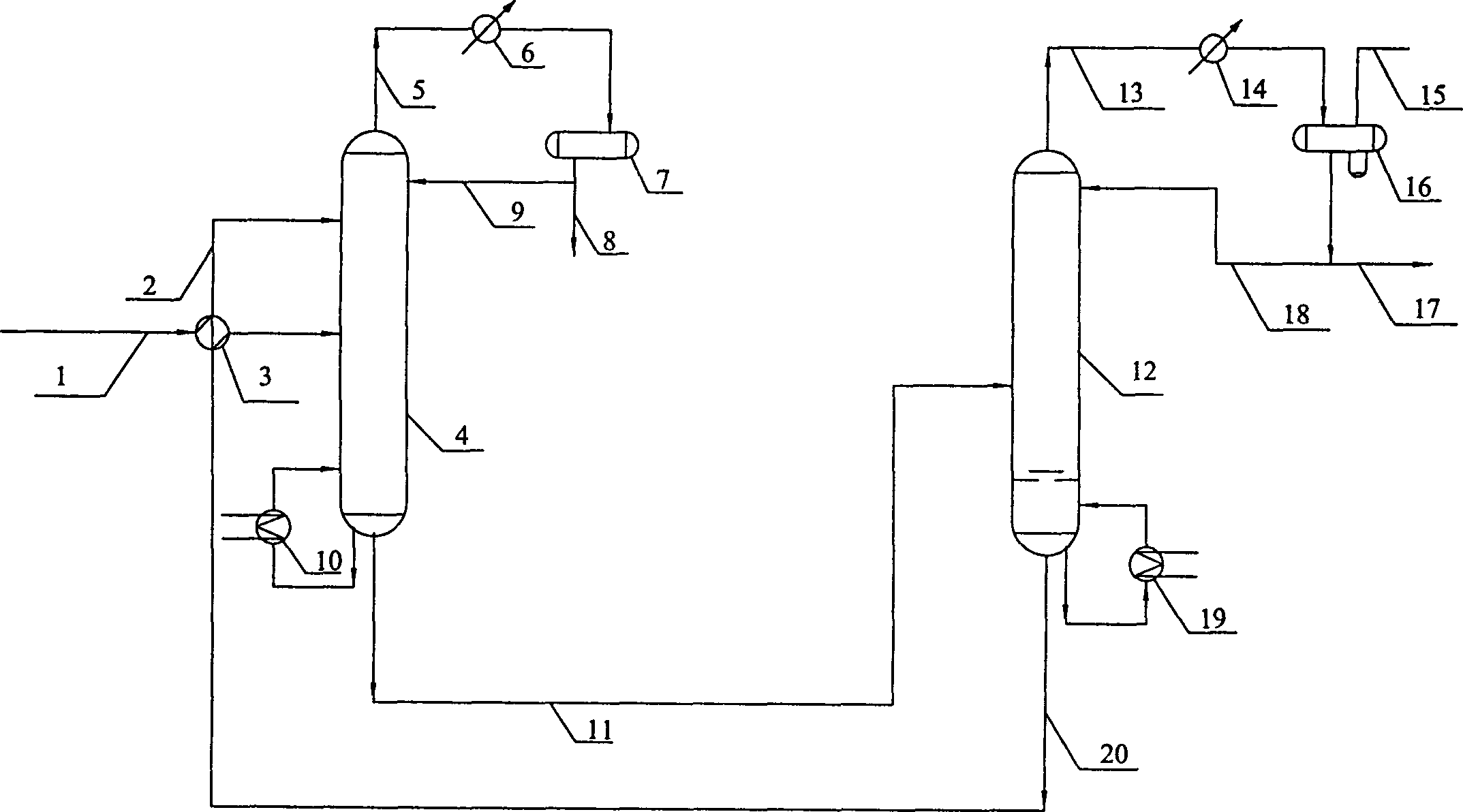

[0022] Benzene is recovered from the benzene fraction of cracking hydrogenated gasoline. The composition of raw materials used is shown in Table 2. The composite solvent used consists of: sulfolane as the main solvent, a mixture of o-xylene and cumene as a cosolvent, and a modifier of N -Formylmorpholine, the content of each component in the composite solvent is listed in Table 1. use figure 1 The process flow shown, the operating conditions of the extractive distillation tower and the solvent recovery tower are shown in Table 3, and the separation results of aromatics are shown in Table 4.

example 2

[0024] Oil C from reforming 6 Benzene products are recovered in the distillate, still using figure 1 process flow. The main solvent of the composite solvent is sulfolane, the auxiliary solvent is o-xylene and cumene, and the modifier is N-methylpyrrolidone. The composition is shown in Table 1, and the raw material composition is listed in Table 2. Extractive distillation tower, solvent recovery tower See Table 3 for the operating conditions and Table 4 for the aromatics separation results.

[0025] As can be seen from the data in Table 3 and Table 4, for the reformed oil with relatively low aromatics content, the composite solvent of the present invention is used for extractive distillation, and when the operating conditions of the recovery tower are relatively mild, not only can it be operated and controlled very stably , and the benzene product with a purity of 99.98% and a sulfur content of 0.2ppm can be obtained with a high recovery rate of 99.6%, and the content of arom...

example 3

[0027] Reclaim benzene from cracking hydrogenated gasoline benzene fraction, raw material used and operating condition are all with example 1, difference is that the main solvent of composite solvent is sulfolane, cosolvent is o-xylene and cumene, without modifier, Its composition is shown in Table 1, and the separation results of aromatics are shown in Table 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com